Biomass binder for clean briquette and preparation method thereof

A biomass and binder technology is applied in the field of biomass binder for clean briquette and its preparation, which can solve the problems of high volatile content in combustion carried-out, insufficient cohesive coal reserves and high ash content, and achieves the goal of making Take the effect of low risk, strong bonding ability and good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

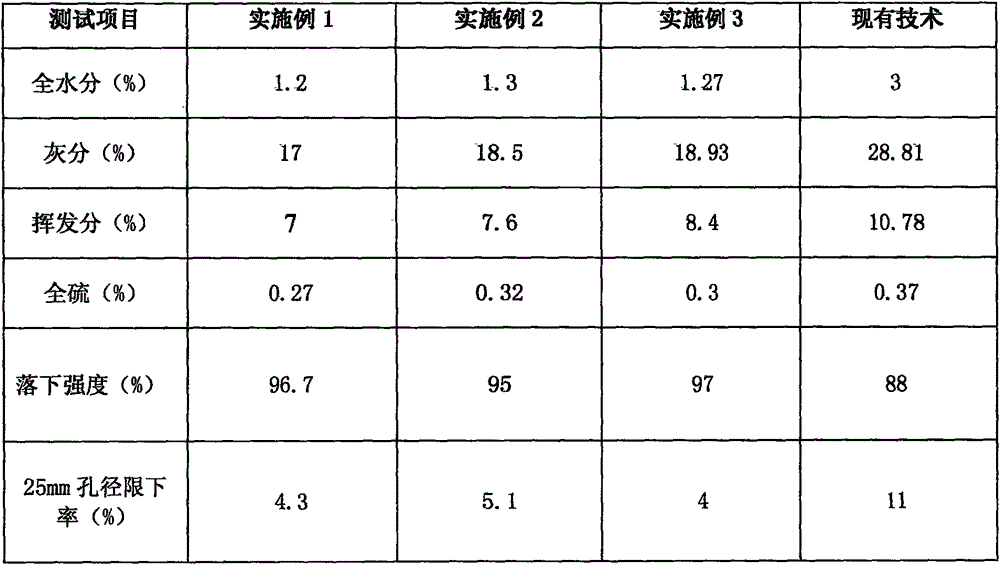

Examples

Embodiment 1

[0028] Embodiment 1: A biomass binder for clean briquettes, comprising the following raw material composition by weight ratio: 10 parts of cornstarch, 5 parts of corn stalks, 5 parts of sawdust, 3 parts of bentonite, 10 parts of sodium hydroxide, 40 parts of water.

[0029] The preparation method of the present embodiment is as follows:

[0030] (1) The cornstarch, corn stalks, sawdust and bentonite are respectively ground by a ball mill and sieved, and the sieving particle size is not less than 200 mesh;

[0031] (2) The corn starch, corn stalks, sawdust and bentonite powder in the step (1) are mixed according to the weight ratio of 10:5:5:3;

[0032] (3) Sodium hydroxide with a mass purity of not less than 99% is dissolved in water at 40-50° C., and the sodium hydroxide and water are stirred evenly according to the weight ratio of 10:40;

[0033] (4) atomize and spray the hot sodium hydroxide solution obtained in step (3) into the mixture obtained in step (2) in a stirrer,...

Embodiment 2

[0034] Embodiment 2: A biomass binder for clean briquettes, comprising the following raw material composition by weight ratio: 15 parts of cornstarch, 10 parts of corn stalks, 8 parts of sawdust, 5 parts of bentonite, 15 parts of sodium hydroxide, 60 parts of water.

[0035] The preparation method of the present embodiment is as follows:

[0036] (1) The cornstarch, corn stalks, sawdust and bentonite are respectively ground by a ball mill and sieved, and the sieving particle size is not less than 200 mesh;

[0037] (2) The corn starch, corn stalks, sawdust and bentonite powder in the step (1) are mixed according to the weight ratio of 15:10:8:5;

[0038] (3) Sodium hydroxide with a mass purity of not less than 99% is dissolved in water at 45-75° C., and the sodium hydroxide and water are stirred evenly according to a weight ratio of 10:40;

[0039] (4) atomize and spray the hot sodium hydroxide solution obtained in step (3) into the mixture obtained in step (2) in a stirrer,...

Embodiment 3

[0040] Embodiment 3: A biomass binder for clean briquettes, comprising the following raw material composition by weight ratio: 20 parts of cornstarch, 15 parts of corn stalks, 10 parts of sawdust, 8 parts of bentonite, 20 parts of sodium hydroxide, 80 parts of water.

[0041] The preparation method of the present embodiment is as follows:

[0042] (1) The cornstarch, corn stalks, sawdust and bentonite are respectively ground by a ball mill and sieved, and the sieving particle size is not less than 200 mesh;

[0043] (2) The corn starch, corn stalks, sawdust and bentonite powder in the step (1) are mixed according to the weight ratio of 15:10:8:5;

[0044] (3) Sodium hydroxide having a mass purity of not less than 99% is dissolved in water at 45-80° C., and the sodium hydroxide and water are stirred evenly according to a weight ratio of 10:40;

[0045] (4) atomize and spray the hot sodium hydroxide solution obtained in step (3) into the mixture obtained in step (2) in a stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com