Photocatalytic nano spray coating and preparation method thereof

A technology of spraying paint and photocatalysis, which is applied in the direction of asphalt paint, coating, etc., can solve the problems of reducing the anti-skid and water seepage performance of the road surface, large color difference of asphalt pavement, poor storage stability, etc., and achieve good wear resistance and low wear , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Make 1kg of photocatalytic nano-spray paint, in which anatase nano-TiO 2 The content is 16% of the quality of the soap solution, and the specific steps are as follows:

[0023] Step 1, preparation of soap solution: add stabilizer CaCl with 0.4% soap solution mass into high-purity water 2 , after heating and fully stirring and dissolving, add the slow-cracked emulsifier SY-CME with 4% soap liquid mass to the solution to dissolve, and then add 3.2% soap liquid mass of sodium polyacrylate dispersant (addition of sodium polyacrylate dispersant) The amount of anatase nano-TiO 2 20% of the mass of the soap solution), and fully stir to dissolve, then slowly add anatase nano-TiO with a mass of 16% of the soap solution 2 , stirred for 15min, kept at 70℃ for later use;

[0024] Step 2, heating the asphalt to a flowing state, keeping the temperature at 140°C for use;

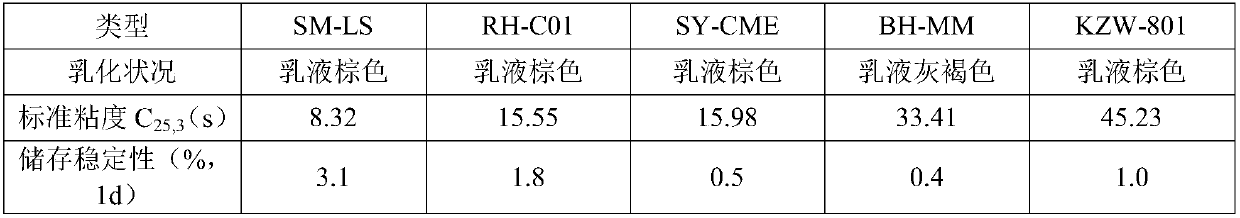

[0025] Step 3, emulsification: first add 0.505kg of soap liquid to the emulsifier, then add 0.485kg of asphal...

Embodiment 2

[0027] Make 1kg of photocatalytic nano-spray paint, in which anatase nano-TiO 2 The content is 10% of the quality of the soap solution, and the specific steps are as follows:

[0028] Step 1, preparation of soap solution: add stabilizer NH of 2% by mass of soap solution to high-purity water 4 Cl, after heating and fully stirring and dissolving, add the slow-cracked emulsifier SY-CME of 3% by mass of soap liquid to the solution to dissolve, and then add sodium polyacrylate dispersant of 2% by mass of soap solution (the amount of sodium polyacrylate dispersant). The amount added is anatase nano-TiO 2 20% of the mass of the soap solution), and fully stir to dissolve, then slowly add anatase nano-TiO with a mass of 10% of the soap solution 2 , stirred for 15min, kept at 65℃ for later use;

[0029] Step 2, heating the asphalt to a flowing state, keeping the temperature at 135°C for use;

[0030] Step 3, emulsification: first add 0.5kg of soap liquid to the emulsifier, then add ...

Embodiment 3

[0032] Make 1kg of photocatalytic nano-spray paint, in which anatase nano-TiO 2 The content is 20% of the quality of the soap solution, and the specific steps are as follows:

[0033] Step 1, preparation of soap solution: add 1% soap solution mass oxalic acid stabilizer into high-purity water, heat and fully stir to dissolve, add 6% soap solution mass SY-CME slow-breaking emulsifier to the solution to dissolve, then Then add 6% sodium polyacrylate dispersant (the amount of sodium polyacrylate dispersant is anatase type nano-TiO) 2 30% of the mass of the soap solution), and fully stir to dissolve, then slowly add anatase nano-TiO with 20% of the mass of the soap solution 2 , stirred for 15min, kept at 68°C for use;

[0034] Step 2, heating the asphalt to a flowing state, keeping the temperature at 138°C for use;

[0035] Step 3, emulsification: firstly add 0.51kg of soap liquid into the emulsifier, then add 0.485kg of asphalt into the emulsifier, emulsification for 3 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com