Anti-flaming coating for plastic products

A technology for flame retardant coatings and plastic products. It is used in fire retardant coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc. It can solve the problems of high halogen content, toxicity, and harm to human health, and achieve thermal stability. The effect of improved thermal stability and flame retardant performance, less addition, improved thermal stability and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

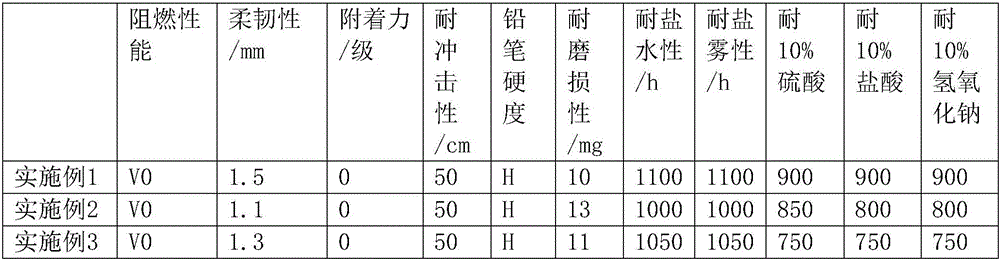

Embodiment 1

[0015] A flame-retardant coating for plastic products, which is composed of the following substances in parts by mass: 25 parts of water-based polyurethane resin, 4 parts of flame-retardant system composition, 11.5 parts of hydrophobic polymer compound, 3.5 parts of barium hydroxide octahydrate, petroleum 4.5 parts of ether, 1.5 parts of high temperature resistant binder, 3 parts of carbonate coupling agent, 2 parts of mixture of cycloalkane and paraffin, 1.5 parts of polyol, 1.5 parts of emulsifier, 4 parts of filler, 25 parts of water; The combustion system composition is formed by mixing silicon compounds, graphene oxide and polyamide.

[0016] The mixing ratio of the silicon compound, graphene oxide and polyamide is 10:1:5. The silicon compound is a mixture of silicon carbide and silicon sulfide, and the ratio of silicon carbide to silicon sulfide is 2:1. The emulsifier is a mixture of cyclohexanone peroxide and polylactate, and the ratio of cyclohexanone peroxide to poly...

Embodiment 2

[0018] A flame-retardant coating for plastic products, which is composed of the following substances in parts by mass: 20 parts of water-based polyurethane resin, 3 parts of flame-retardant system composition, 8 parts of hydrophobic polymer compound, 2 parts of barium hydroxide octahydrate, petroleum 3 parts of ether, 1 part of high temperature resistant binder, 2 parts of carbonate coupling agent, 1 part of mixture of cycloalkane and paraffin, 1 part of polyol, 1 part of emulsifier, 3 parts of filler, 20 parts of water; The combustion system composition is formed by mixing silicon compounds, graphene oxide and polyamide.

[0019] The mixing ratio of the silicon compound, graphene oxide and polyamide is 10:1:5. The silicon compound is a mixture of silicon carbide and silicon sulfide, and the ratio of silicon carbide to silicon sulfide is 2:1. The emulsifier is a mixture of cyclohexanone peroxide and polylactate, and the ratio of cyclohexanone peroxide to polylactate is 1:2. ...

Embodiment 3

[0021] A flame-retardant coating for plastic products, which is composed of the following substances in parts by mass: 30 parts of water-based polyurethane resin, 5 parts of flame-retardant system composition, 15 parts of hydrophobic polymer compound, 5 parts of barium hydroxide octahydrate, petroleum 6 parts of ether, 2 parts of high temperature resistant binder, 4 parts of carbonate coupling agent, 3 parts of mixture of cycloalkane and paraffin, 2 parts of polyol, 2 parts of emulsifier, 5 parts of filler, 30 parts of water; The combustion system composition is formed by mixing silicon compounds, graphene oxide and polyamide.

[0022] The mixing ratio of the silicon compound, graphene oxide and polyamide is 10:1:5. The silicon compound is a mixture of silicon carbide and silicon sulfide, and the ratio of silicon carbide to silicon sulfide is 2:1. The emulsifier is a mixture of cyclohexanone peroxide and polylactate, and the ratio of cyclohexanone peroxide to polylactate is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com