Preparation of mineral radiative powder and application thereof to building heat-insulating coating

A technology of radiant powder and minerals, applied in the field of materials, can solve the problems of low emissivity of fillers, limiting the heat insulation effect of coatings, and the failure of coatings to achieve heat insulation, and achieve improved wet rub resistance, improved rheology, and improved Effect of Coating Hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The first step: first prepare mineral radiation powder, the ratio of raw materials is shown in Table 1, and the unit is Kg;

[0031] Table I

[0032]

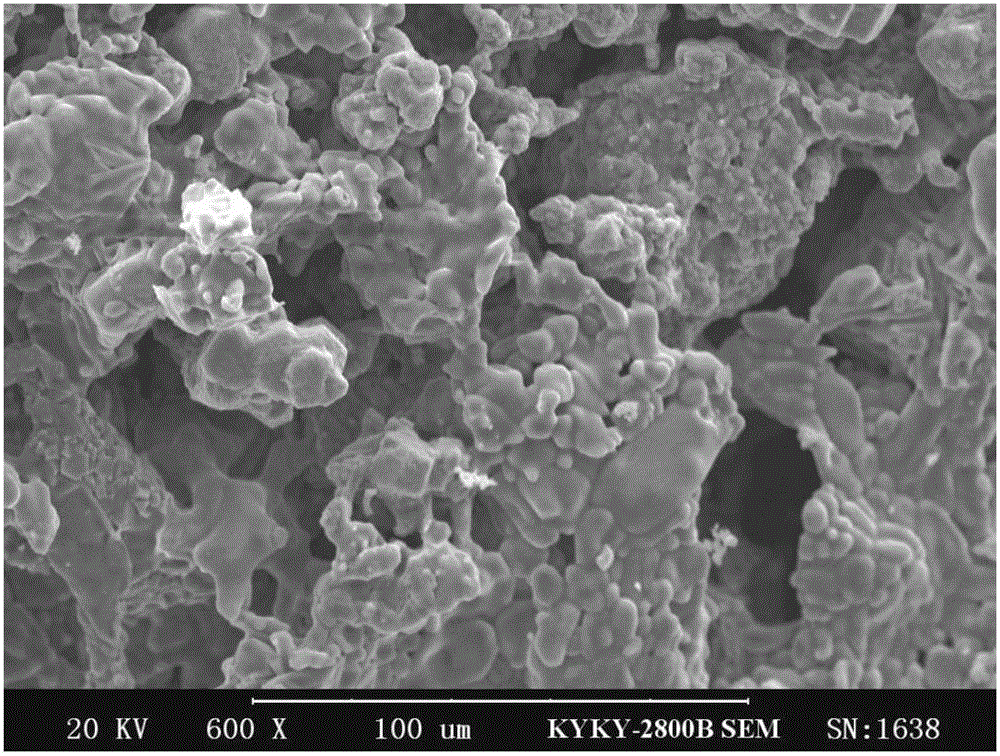

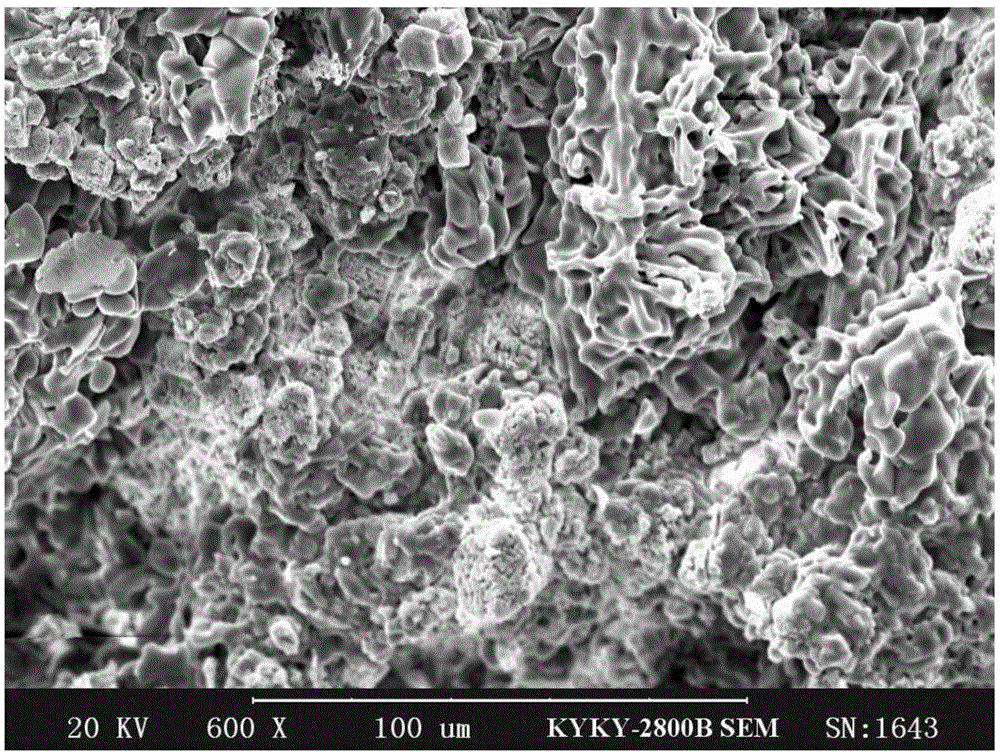

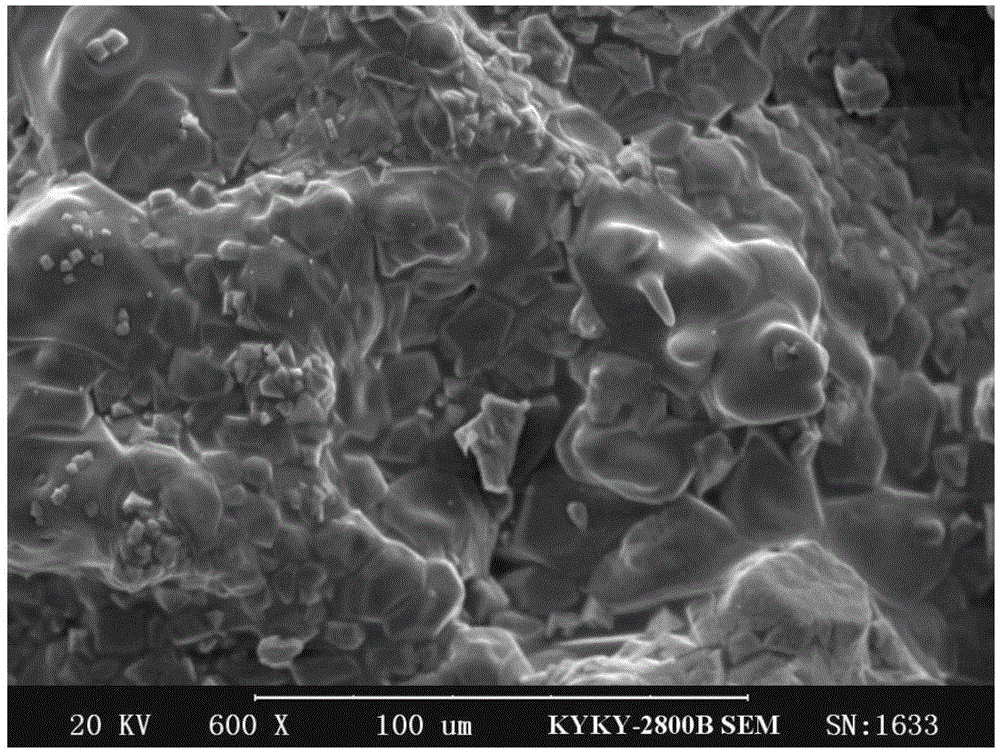

[0033] The preparation method is as follows: After uniformly mixing the components in Table 1 in proportion, they are still pressed and formed under a pressure of 20 MPa, then sintered at 900°C for 30 minutes, and then heated to 1000°C for 30 minutes to continue sintering for 30 minutes, and finally again It is sufficient to raise the temperature to 1250°C in 30 minutes and continue for 30 minutes. The SEM photos of the powder calcined at three temperatures are shown in Figure 1-3 ,From Figure 1-3 It can be seen that as the calcination temperature increases, the lattice structure changes continuously. At 900°C, the edges of the powder particles begin to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com