Diluent for fluorinated polyurethane enamel and spraying method thereof

A fluoropolyurethane enamel and thinner technology, applied in the field of coatings, can solve the problems of being easily affected by the surrounding environment, uneven color tone, increasing construction difficulty, etc., and achieve difficult control of the quality of the paint film, smooth appearance, and uniform and continuous paint film. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The experimental material is No. 12 duralumin, thickness δ1.5, size 100cm×100cm anodized aluminum plate sample, after being cleaned by white cloth dipped in diluent respectively, spray TB06-9 zinc yellow epoxy polyurethane primer, primer The paint thickness is 30μm±5μm, and it is dried at 40℃~50℃ for 6h.

[0025] Fluorine polyurethane enamel is TS96-71 fluorine polyurethane enamel, commercially available

[0026] First, the deployment of paint:

[0027] Step a Weigh the two components of fluoropolyurethane matt enamel according to the specified ratio, add the fluorine-containing hydroxyl resin, dispersant, pigment, matting agent and curing agent in component one into the stirring container in sequence, and while stirring continuously, Slowly add the isocyanate resin of component two to prepare fluoropolyurethane enamel.

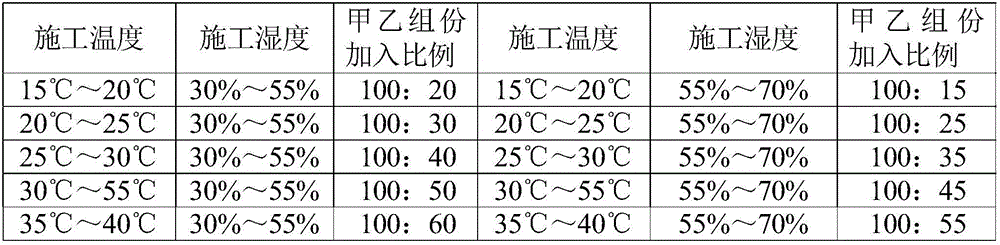

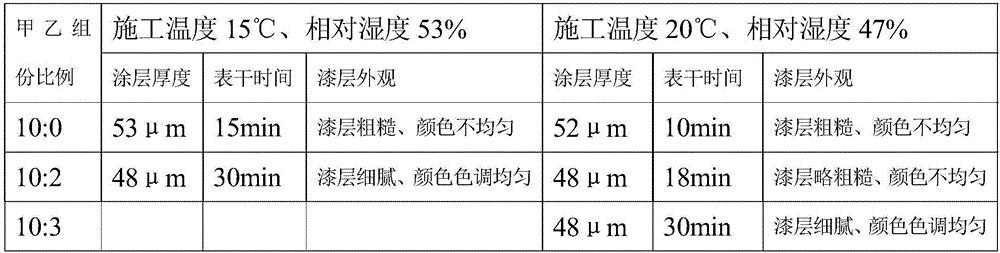

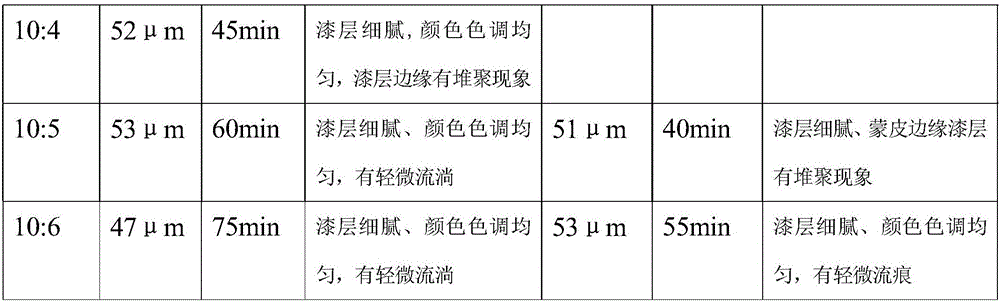

[0028] In step b, mix components A and B of the diluent in proportions of 10:0, 10:2, 10:3, 10:4, 10:5, and 10:6, and stir evenly. The mass account...

Embodiment approach

[0034] Take 5 identical aluminum plate samples, and spray 2 coats of topcoat randomly on the test pieces placed on the upper surface of the wing in different construction environments of different temperatures and humidity respectively. The connection width is 50%, and the spray gun distance is 150mm-250mm. In order to ensure the accuracy of the experimental results, the thickness of the topcoat was controlled at 50 μm ± 5 μm, and the painted test piece was dried at 40°C to 50°C for 6 hours. Check and verify the paint adhesion, paint appearance quality and surface drying time of the test piece. The experimental results are shown in Table 2. Among them, the adhesion is tested by the cross-cut method, and the adhesion in this embodiment is 0 grade; the dry time refers to the time required for the surface of a wet paint film of a certain thickness to change from liquid to solid under specified drying conditions . The appearance of the paint film is checked by comparing it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com