Waterproof plastic and wood composite material and preparation method thereof

A technology of wood-plastic composite material and wood powder, which is applied in the field of waterproof wood-plastic composite material and its preparation, and can solve the problems of deformation, affecting the performance of materials, and the surface of hollow drum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

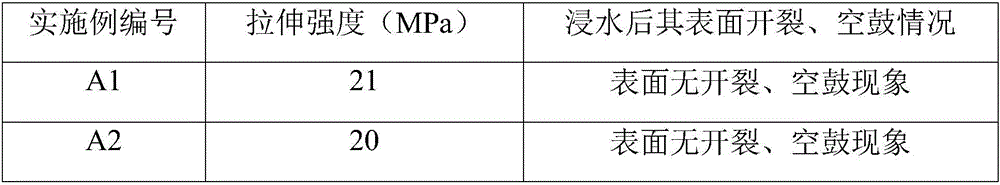

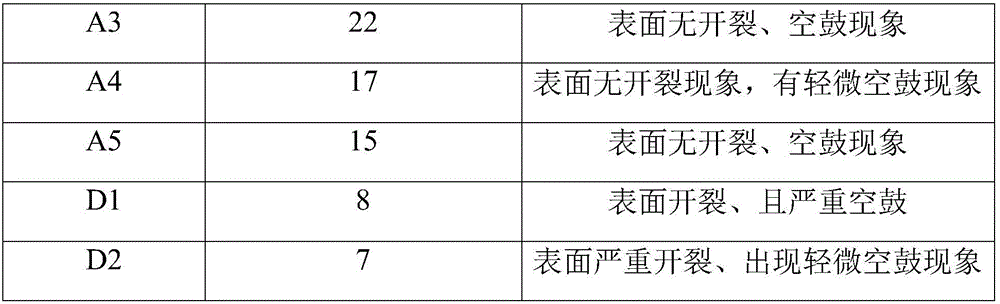

Examples

preparation example Construction

[0013] The invention provides a method for preparing a waterproof plastic-wood composite material, wherein the preparation method includes: mixing polypropylene and low-density polyethylene, soaking in sodium hydroxide solution, and filtering for later use; Dry at 80-100°C for 10-30min and set aside; mix the treated polypropylene, low-density polyethylene, wood powder, wollastonite, azodicarbonamide, silane coupling agent KH550 and epoxy resin, The waterproof plastic-wood composite material is obtained after hot pressing and shaping.

[0014] In order to make the prepared wood-plastic composite material have better waterproof performance and further improve its mechanical strength, in a preferred embodiment of the present invention, relative to 100 parts by weight of polypropylene, the low-density polyethylene The consumption of said wood powder is 70-90 parts by weight, the consumption of said wood powder is 150-180 parts by weight, the consumption of said wollastonite is 10-...

Embodiment 1

[0022] 100g polypropylene and 75g low-density polyethylene are mixed and soaked in sodium hydroxide solution (concentration is 30% by weight), filtered and set aside; 160g wood powder is dried at 80°C for 10min, set aside; treated Polypropylene, low-density polyethylene, wood powder, 14g wollastonite, 4g azodicarbonamide, 8g silane coupling agent KH550 and 18g epoxy resin were mixed and hot-pressed (at a temperature of 120°C) to obtain a waterproof plastic. Wood composite A1.

Embodiment 2

[0024] 100g polypropylene and 85g low-density polyethylene are mixed and soaked in sodium hydroxide solution (concentration is 45% by weight), filtered and set aside; 170g wood flour is dried at 100°C for 30min, set aside; treated Polypropylene, low-density polyethylene, wood flour, 16g wollastonite, 6g azodicarbonamide, 10g silane coupling agent KH550 and 20g epoxy resin were mixed and hot-pressed (at a temperature of 130°C) to obtain a waterproof plastic. Wood composite A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com