Preparation method of micro-crosslinked-structure high-temperature-resistant salt-resistant well cementing cement slurry filtrate loss reducer

A technology of cementing cement slurry and fluid loss reducing agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of no guidance plan and low reaction temperature, etc., and achieve strong water-locking ability, The effect of lowering the reaction temperature and increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

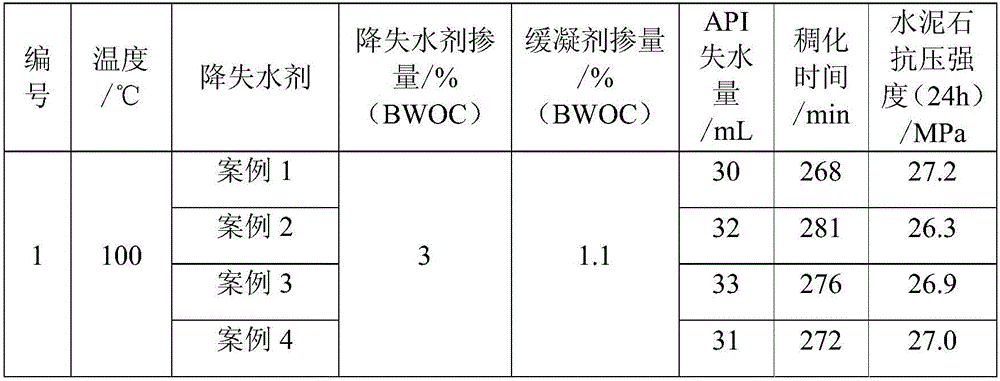

Embodiment 1

[0022] Example 1: The preparation method of the micro-crosslinked high-temperature and salt-resistant cementing slurry fluid loss reducer of the present invention includes the following process steps: ① Weigh 2 -Acrylamido-2-methylpropanesulfonic acid, acrylamide, unsaturated polycarboxylic acid (itaconic acid), N-vinylpyrrolidone, these four kinds of raw materials are dissolved in deionized water to obtain a solution, and the pH of the solution is adjusted value to 7 (mass percent concentration can be used to adjust the pH value of 30% NaOH solution), add 0.2% of the crosslinking agent N, N-methylenebisacrylamide and the total amount of reaction monomers 0.5% molecular weight regulator sodium methacryl sulfonate, prepared into a solution with a monomer concentration of 20%. ② Afterwards, pour this solution into a three-neck flask equipped with a thermometer and a stirring device, heat (react) in an oil bath, and raise the temperature to 45°C. ③ After the temperature stabiliz...

Embodiment 2

[0023] Example 2: The preparation method of the micro-crosslinked high temperature and salt resistant cement slurry fluid loss reducer of the present invention includes the following process steps: ① Weigh 2 -Acrylamido-2-methylpropanesulfonic acid, acrylamide, unsaturated polycarboxylic acid (maleic acid), N-vinylpyrrolidone, these four kinds of raw materials are dissolved in deionized water to obtain a solution, and the pH of the solution is adjusted value to 6.5 (mass percent concentration can be used to adjust the pH value of 30% NaOH solution), add 0.13% of the crosslinking agent N, N-methylenebisacrylamide and the total amount of reaction monomers It is 0.45% molecular weight regulator thioglycolic acid, and it is prepared into a solution with a monomer concentration of 18%. ②Pour this solution into a three-neck flask equipped with a thermometer and a stirring device, heat it in an oil bath, and raise the temperature to 48°C. ③ After the temperature stabilizes, add an i...

Embodiment 3

[0024] Example 3: The preparation method of the micro-crosslinked high temperature and salt resistant cement slurry fluid loss reducer of the present invention includes the following process steps: ① Weigh 2 -Acrylamido-2-methylpropanesulfonic acid, acrylamide, unsaturated polycarboxylic acid (fumaric acid), N-vinylpyrrolidone, these four kinds of raw materials are dissolved in deionized water to obtain a solution, and the pH of the solution is adjusted value to 7.5 (mass percentage concentration can be used to adjust the pH value of 30% NaOH solution), add the crosslinking agent N that accounts for 0.18% of the total amount of reaction monomers, N-methylenebisacrylamide and the total amount of reaction monomers It is 0.58% molecular weight regulator mercaptopropionic acid, and it is prepared into a solution with a monomer concentration of 23%. ②Pour this solution into a three-neck flask equipped with a thermometer and a stirring device, heat it in an oil bath, and raise the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com