Sludge film composite SBR water treatment process

A water treatment and process technology, applied in the field of mud film composite SBR water treatment process, can solve the problems of packing leakage, discharge with water, poor effect, etc., and achieve the effects of high volume load, continuous water in and out, and simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

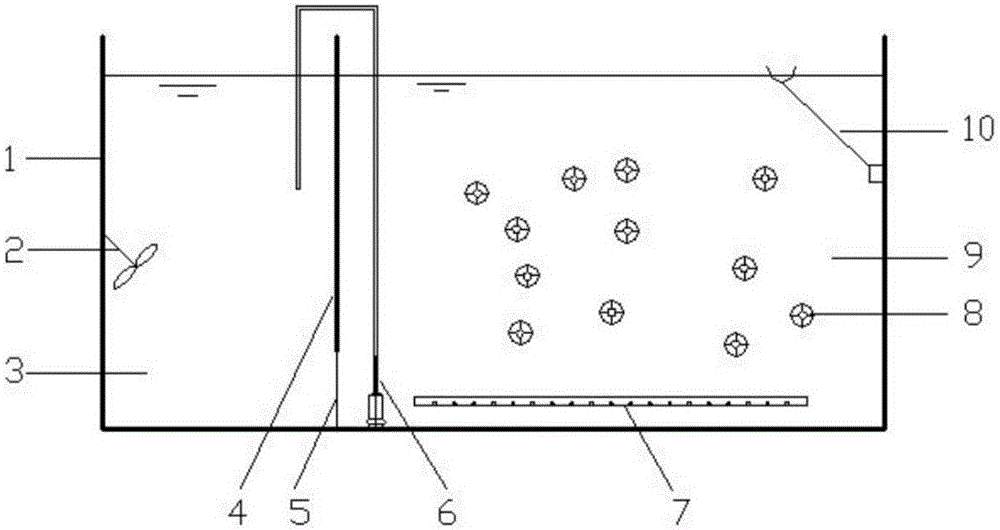

Embodiment 1

[0031] Take the effluent from the primary sedimentation tank of a city sewage treatment plant in winter as the influent water, the water temperature is 12-15°C, the concentration of BOD in the water is 165-180mg / L, the concentration of ammonia nitrogen is 30-40mg / L, the concentration of TN is 35-50mg / L, and the concentration of TP is 2- 3mg / L. Reactor effective volume 3.0m 3 , of which 1.2m in zone A 3 , 1.8m in zone B 3 . The specific surface area of the suspended filler used is 620m 2 / m 3 , the filling rate is 20%, and the specific gravity before filming is 0.98. The design operation cycle is: water inflow 2h, reaction 1h, precipitation 0.5h, decanting water 0.5h. Single water change 0.8m 3 .

[0032] When starting up, the return sludge of the water plant is used as inoculation sludge, and new suspended filler is added. In the start-up phase, the single water change volume is 0.4m 3 . After 3 days of start-up, the filler is wetted and begins to hang the film, a...

Embodiment 2

[0034] Take the effluent from the primary sedimentation tank of a sewage treatment plant in winter as the influent, the water temperature is 12-15°C, the concentration of BOD in the water is 125-150mg / L, the concentration of ammonia nitrogen is 32-44mg / L, the concentration of TN is 37-50mg / L, and the concentration of TP is 2-3mg / L. Reactor volume 5.4m 3 , of which 2.4m in zone A 3 , 3.0m in Zone B 3 . A total of 2 monomer reactors are operated alternately. The specific surface area of the suspended filler used is 620m 2 / m 3 , the filling rate is 25%, and the specific gravity before filming is 0.98. Due to the lack of carbon source in the water, a carbon source dosing device is installed in Area A to supplement the carbon source during the water inflow and reaction stage. The design operation cycle is: water inflow 2h, reaction 1h, precipitation 0.5h, decanting water 0.5h. 2 reactors alternately feed water to realize continuous water inlet and outlet operation, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com