Micro-nano iron sulfide/porous carbon composite material, preparation method thereof and seaweed biomass application

A composite material, iron sulfide technology, applied in the direction of iron sulfide, application, fertilizer mixture, etc., to achieve the effect of low cost, guaranteed operability and safety, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

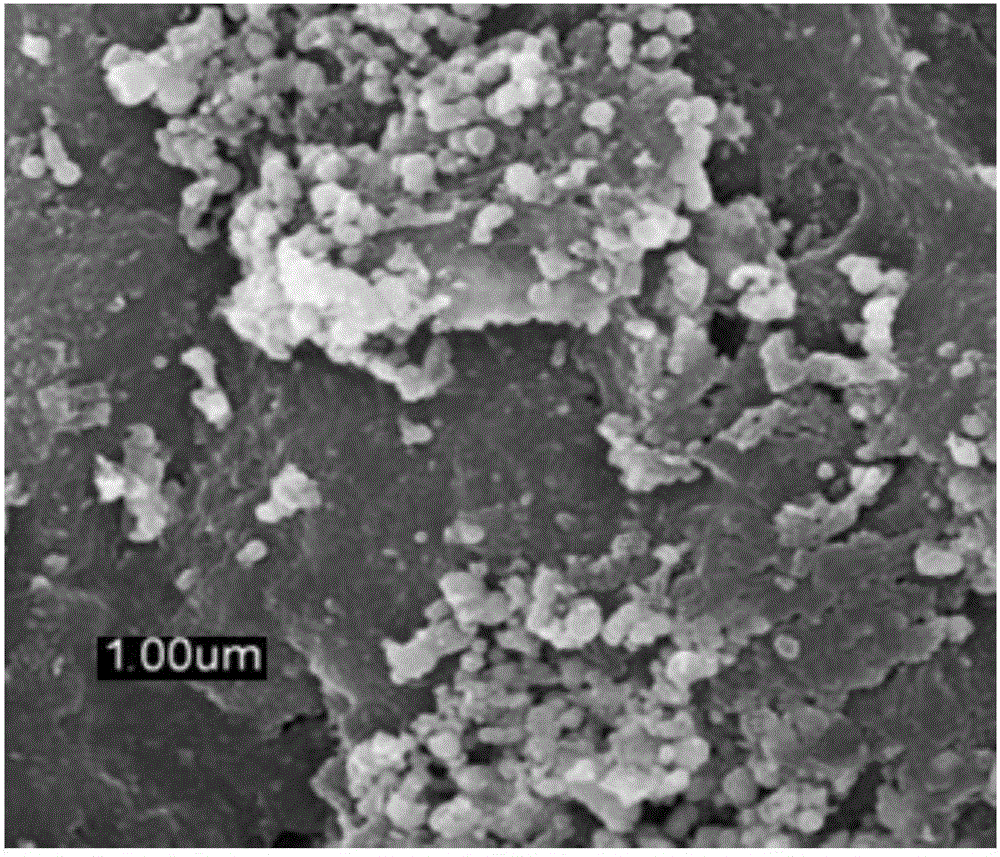

[0027] During the outbreak of green tide, the green tide alga Enteromorpha was salvaged in the coastal waters of Qingdao or the accumulated Enteromorpha was collected and crushed until the biomass particle size was 1×10 7 MPN / g) and ferrous sulfate were added to the above-mentioned seaweed slurry according to the ratio of 1% (mass ratio), homogenized and mixed, and the sulfate bioreduction reaction in the homogenized slurry was started at a temperature of 35 ° C. After 72 hours of reaction, sulfide The iron / seaweed biomass mixture was directly put into the hydrothermal reactor, and subjected to a rapid hydrothermal reaction at 170°C for 24 hours. After the hydrothermal reaction was completed, the black solid remaining at the bottom of the reactor was collected, dried in vacuum, and analyzed by scanning electron microscopy. The iron sulfide particles on the surface are micro-nano particles, so that the micro-nano iron sulfide / seaweed-based biochar composite material is prepared....

Embodiment 2

[0029] Collect the dried Gracilaria and asparagus, wash the seaweed to remove the salt, then crush the biomass to a particle size of 1×10 7 MPN / g) and ferrous sulfate are added to the seaweed slurry according to the ratio of 2% (mass ratio), homogenized and mixed, and the sulfate bioreduction reaction is started at a temperature of 25 ° C. After 120 hours of reaction, micronano iron sulfide / seaweed raw materials are generated. mixture of substances. The generated iron sulfide / seaweed biomass mixture was directly put into the hydrothermal reaction kettle, and the rapid hydrothermal reaction was carried out at 190°C for 10 hours. The black solid remaining at the bottom of the reaction kettle was collected and freeze-dried. The iron sulfide loaded on the porous carbon was observed by scanning electron microscope The particles are micro-nano particles, and the micro-nano iron sulfide / seaweed-based biochar composite material is prepared. The average particle size of the prepared p...

Embodiment 3

[0031] Collect kelp processing waste in a kelp processing factory, wash the kelp processing waste, remove the salt, then crush the kelp processing waste to a particle size of 1×10 7 MPN / g) and ferrous sulfate are added to the seaweed pulp in a ratio of 5% (mass ratio), homogenized and mixed, and the sulfate bioreduction reaction is started at a temperature of 15°C, and the iron sulfide / seaweed biomass mixture is generated after 240 hours of reaction . Put the mixture directly into the hydrothermal reaction kettle, and perform a rapid hydrothermal reaction at 220°C for 2 hours. After the hydrothermal reaction is over, collect the black solid remaining at the bottom of the reaction kettle and dry it in vacuum. The iron sulfide loaded on the porous carbon is observed by scanning electron microscope. The particles are micro-nano particles, that is, the micro-nano iron sulfide / seaweed-based biochar composite material is prepared. The average particle size of the prepared porous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com