Pipeline structure and rapid laying method for single-layer vacuum pipeline or double-layer vacuum pipeline of pipeline structure

A double-layer vacuum and vacuum pipeline technology, applied in the direction of roads, tracks, tunnel systems, etc., can solve the problems of high structural elastic modulus, high production cost, low erection efficiency, etc., and achieve low cost, convenient processing, and convenient and rapid erection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

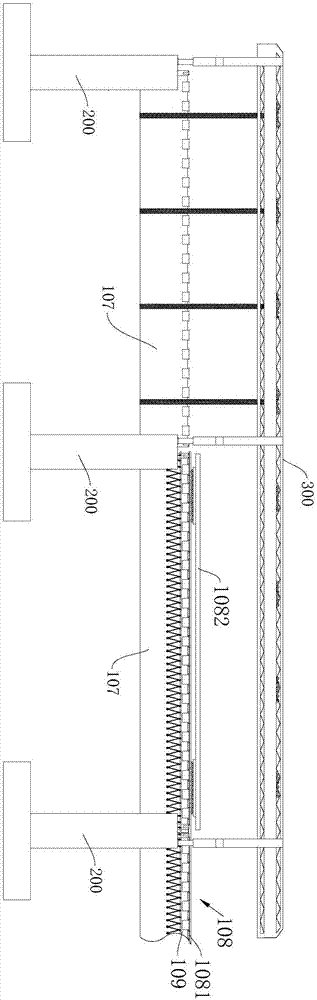

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

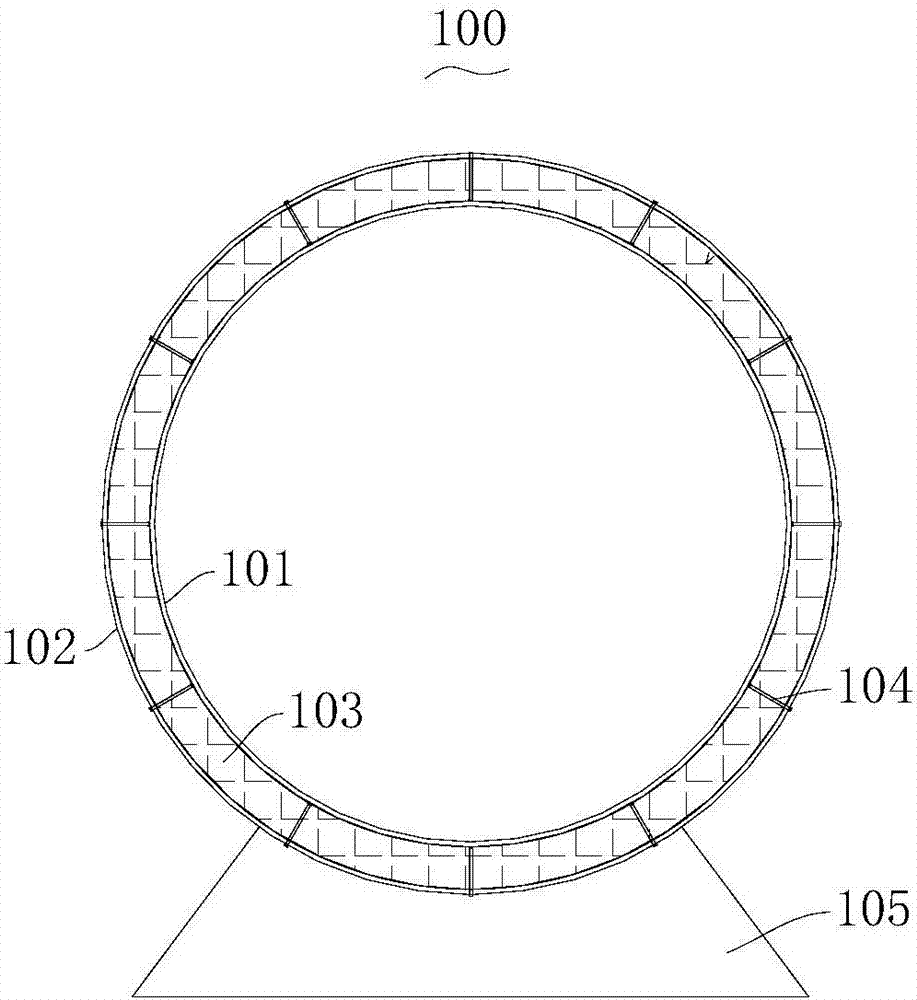

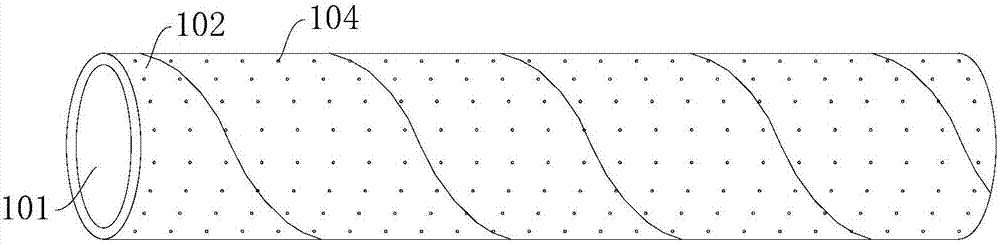

[0028] combine Figure 1 to Figure 2 As shown, this embodiment provides a pipeline structure, including an inner spiral tube 101, an outer spiral tube 102, and a high-strength rigid filling arranged between the inner layer spiral tube 101 and the outer layer spiral tube 102. material 103, and a tension member 104 for combining the inner layer spiral tube 101 and the outer layer spiral tube 102 with the hard filler 103, and the tension member 104 is respectively connected with the inner layer spiral tube 101 Fastened with the outer spiral tube 102, and the inner diameter of the inner spiral tube 101 is greater than or equal to 3m and less than or equal to 15m. In this embodiment, the inner diameter of the inner spiral tube 101 is preferably 6m.

[0029] In this embodiment, the inner spiral tube 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com