Intelligent conveying device of containers in warehouse

An intelligent handling and container technology, applied in the direction of hoisting device, lifting frame, etc., can solve the problems of low degree of automation and integration, difficult to meet the requirements of high efficiency, process and rapid response, and large space occupation, so as to improve the handling efficiency and Safety, reduced labor and handling cycles, smooth hoisting and handling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

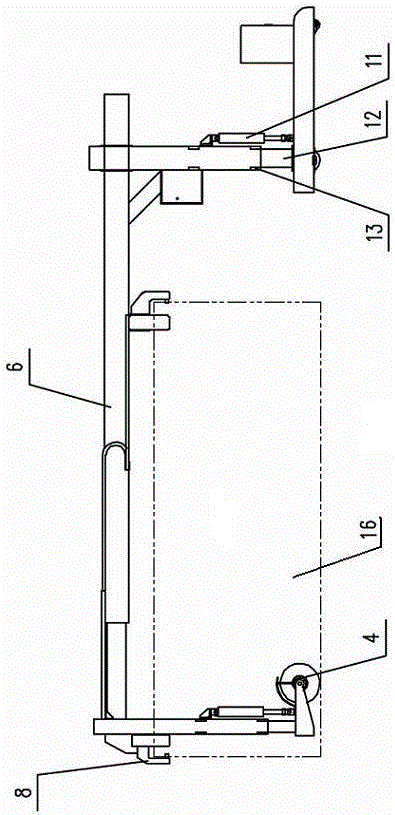

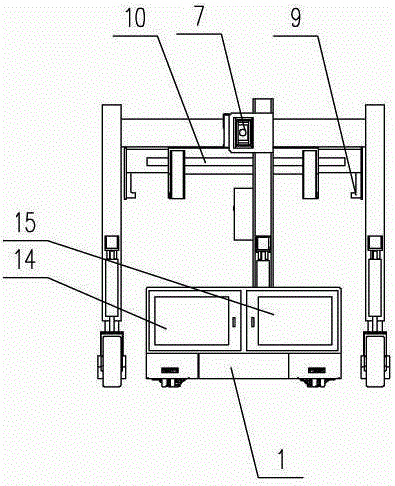

[0017] The structure of the container intelligent handling device in the warehouse of the present invention is as follows: figure 1 and figure 2 Shown, will be made up of car body chassis device 1, driving power system, length adjustment mechanism, clamping mechanism, hydraulic jacking mechanism, hydraulic control system 14, electrical control system 15.

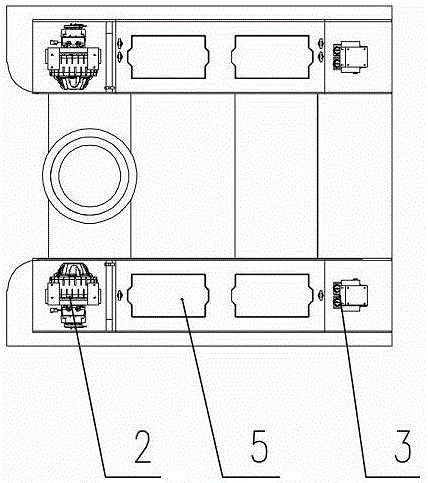

[0018] The structure of the car body chassis device 1 is as image 3 As shown, it is a welded part with good structural strength, which is used to install other equipment components and plays an integral role in supporting the container hoisting. The driving wheel set 2, universal wheel set 3, battery set 5, hydraulic pressure Both the control system 14 and the electrical control system 15 are installed on the vehicle body chassis device 1 .

[0019] The driving power system is composed of a drive wheel set 2, a universal wheel set 3, a rear directional wheel set 4, and a battery pack 5. The drive wheel set 2 has 2 drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com