Base station equipment lifting auxiliary device

A technology for auxiliary devices and base station equipment, which is applied to hoisting devices, mechanical equipment, portable lifting devices, etc., can solve the problems of inconvenient adjustment of angle, safe fixation, increased weight of high-altitude working parts, and inability to ensure the stability of hoisting. The effect of hoisting, improving stability and quick connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

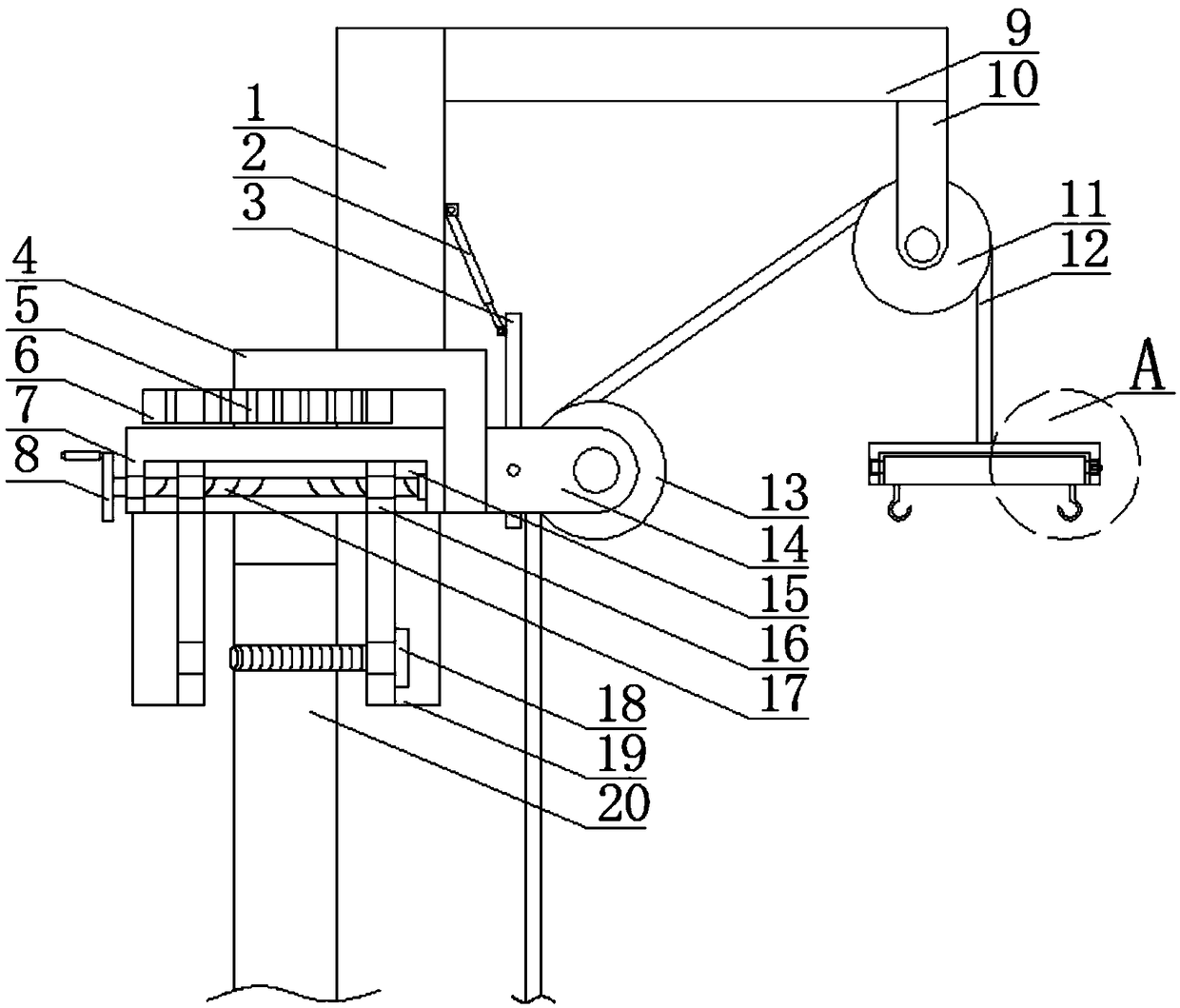

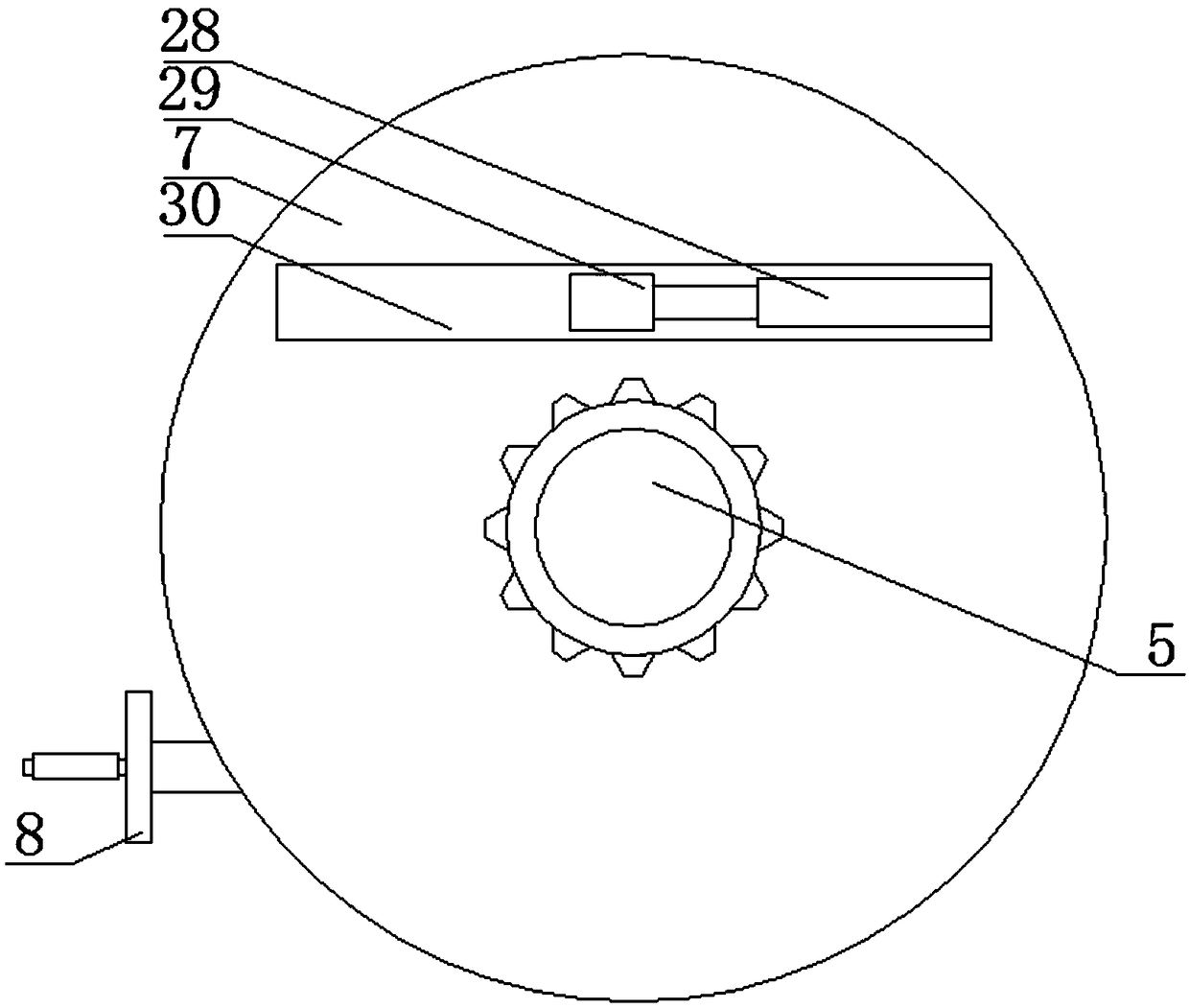

[0026] refer to figure 1 , 3 , a base station equipment hoisting auxiliary device, comprising a turntable 7, the upper end of the turntable 7 is rotatably connected with a gear 5, the upper end side of the turntable 7 is provided with a bearing groove 30, and a second electric telescopic motor is fixed on the side wall of one end of the bearing groove 30. Rod 28, one end of the second electric telescopic rod 28 is fixed with bearing block 29, and the second electric telescopic rod 28 can push bearing block 29 to reciprocate in bearing groove 30, and the upper end of bearing block 29 is fixed with straight rack 6, and straight The rack 6 is meshed with the gear 5, so that the bearing block 29 can drive the spur rack 6 to reciprocate, and the movement of the spur rack 6 can drive the gear 5 to rotate, thereby facilitating the adjustment of the direction and the installation by the staff;

[0027] The upper end of the gear 5 is fixed with an L-shaped plate 4, and the rotation of...

Embodiment 2

[0030] refer to figure 1 , 3 , 4, a base station equipment hoisting auxiliary device, comprising a turntable 7, the upper end of the turntable 7 is rotatably connected with a gear 5, and one side of the upper end of the turntable 7 is provided with a bearing groove 30, and one end side wall in the bearing groove 30 is fixed with a second Electric telescopic rod 28, one end of the second electric telescopic rod 28 is fixed with bearing block 29, and the second electric telescopic rod 28 can push bearing block 29 to reciprocate in bearing groove 30, and the upper end of bearing block 29 is fixed with straight rack 6, And the spur rack 6 is meshed with the gear 5, so that the bearing block 29 can drive the spur rack 6 to reciprocate, and the movement of the spur rack 6 can drive the gear 5 to rotate, thereby making it easy to adjust the direction and convenient for the staff to install;

[0031] The upper end of the gear 5 is fixed with an L-shaped plate 4, and the rotation of t...

Embodiment 3

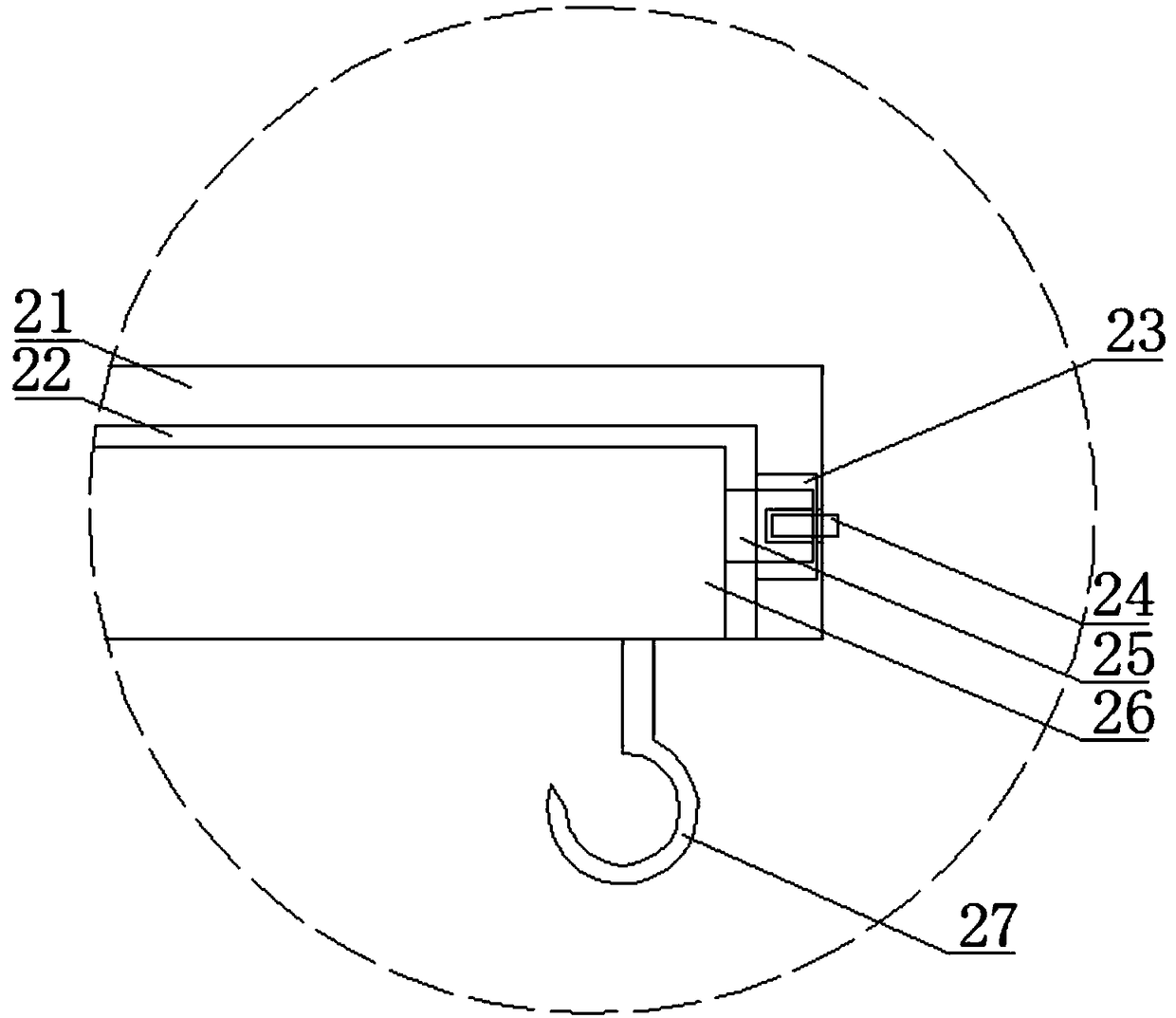

[0038] refer to figure 1 , 2 3. An auxiliary device for hoisting base station equipment, comprising a turntable 7, the upper end of the turntable 7 is rotatably connected with a gear 5, and one side of the upper end of the turntable 7 is provided with a bearing groove 30, and a side wall at one end in the bearing groove 30 is fixed with a second Electric telescopic rod 28, one end of the second electric telescopic rod 28 is fixed with bearing block 29, and the second electric telescopic rod 28 can push bearing block 29 to reciprocate in bearing groove 30, and the upper end of bearing block 29 is fixed with straight rack 6, And the spur rack 6 is meshed with the gear 5, so that the bearing block 29 can drive the spur rack 6 to reciprocate, and the movement of the spur rack 6 can drive the gear 5 to rotate, thereby making it easy to adjust the direction and convenient for the staff to install;

[0039] The upper end of the gear 5 is fixed with an L-shaped plate 4, and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com