Control structure for portable numerical control (NC) flame cutting machine

A technology of flame cutting machine and control structure, applied in gas flame welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of operator's health hazards, large iron dust and dust, low production efficiency, etc., to improve health Guarantee, production cost reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

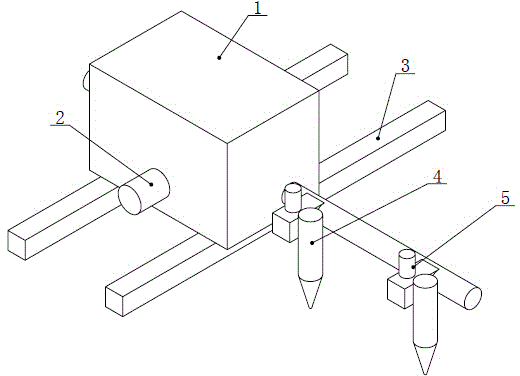

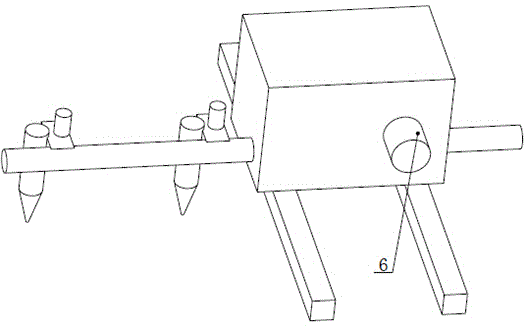

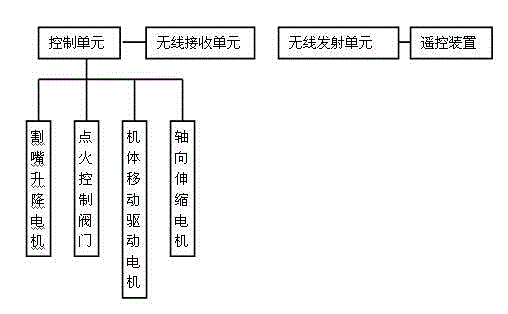

[0012] Such as Figure 1~Figure 3 As shown, a control structure of a portable numerical control flame cutting machine includes a remote control device. The remote control device is connected to the wireless receiving unit of the control unit through a wireless transmitting unit connected to itself. The control unit is connected with a cutting tool that drives the cutting nozzle 4 to lift Nozzle lifting motor 5, ignition control valve for controlling the ignition of the cutting nozzle 4, axial telescopic motor 6 for driving the cutting nozzle 4 to move axially, and a body moving drive motor 2 for driving the cutting machine body 1 to move horizontally on the horizontal guide rail 3, remote control The device is equipped with cutting nozzle lifting motor button, ignition control valve button, axial telescopic motor button and body moving drive motor button, through the buttons to realize the corresponding start, electric, feed movement, each cutting nozzle lifting motor and ignit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com