A pass-through electrolytic deburring machine

A deburring machine and raceway technology, applied in electric machining equipment, electrochemical machining equipment, accessories, etc., can solve the problems of inconvenient maintenance and replacement of bearings, damage to positioning blocks and workpieces, slowing down the production cycle, etc. The effect of convenient maintenance and replacement of accessories, increasing contact area, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

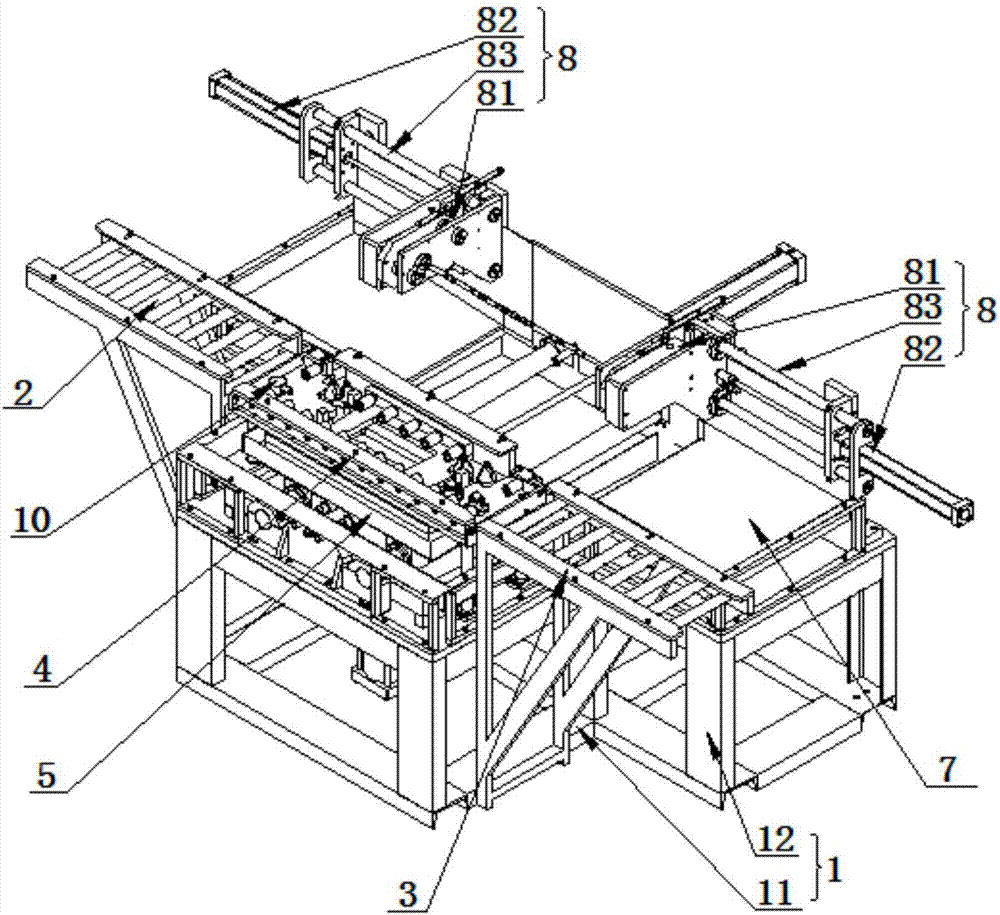

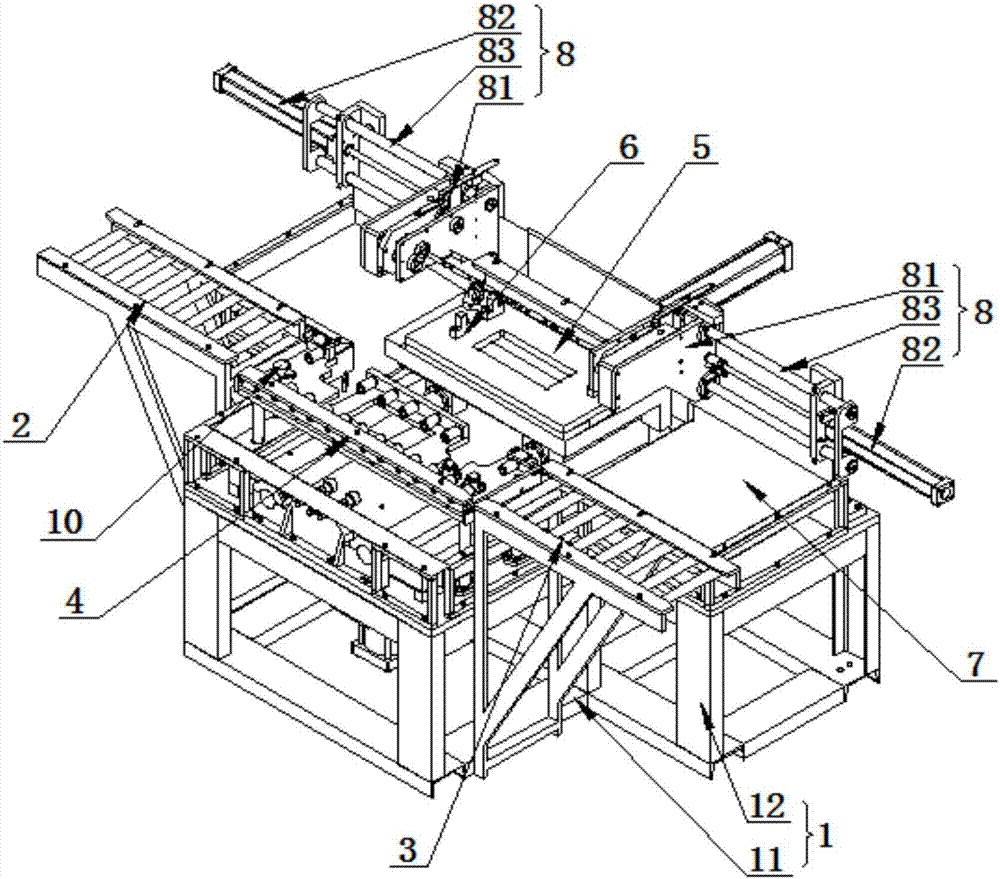

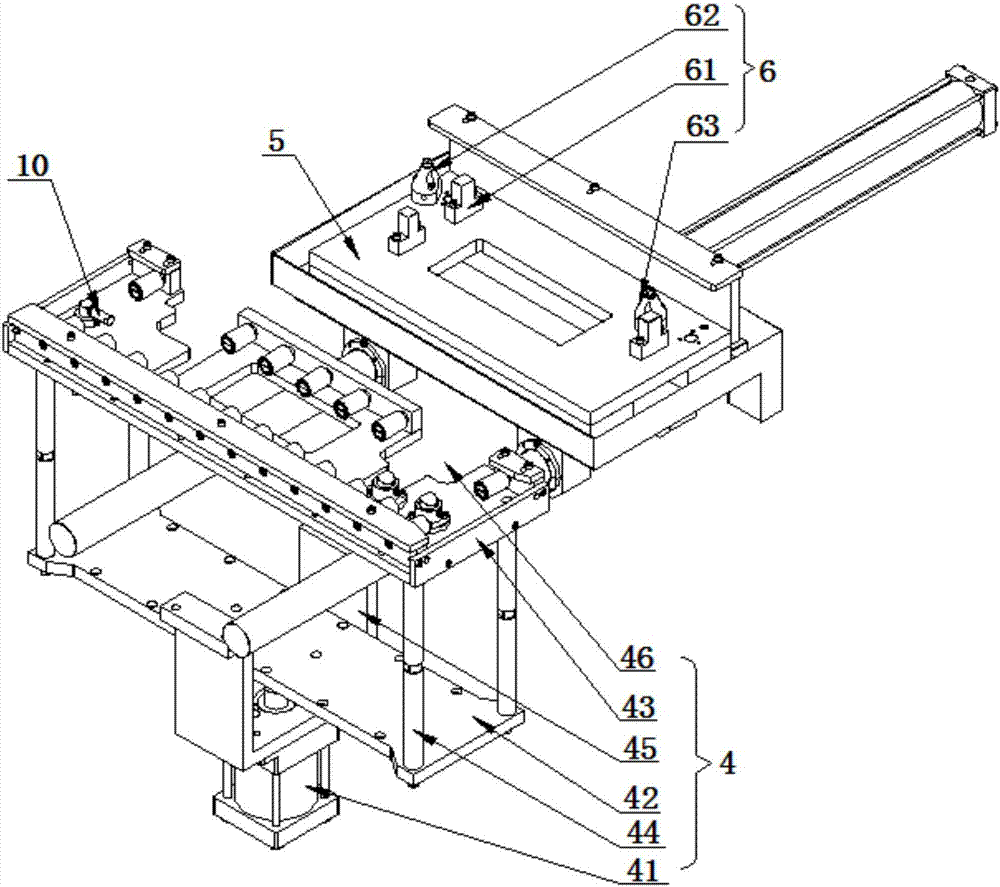

[0030] refer to Figure 1-9 , a through-type electrolytic deburring machine of the present invention includes a base 1, and a first raceway 2 and a second raceway 3 connected with the cylinder block production line are symmetrically arranged at both ends of the base 1, so that the cylinder block electrolysis The deburring process is on the same production line as other processes of the cylinder block. On the base 1 between the first raceway 2 and the second raceway 3, there is a lifting raceway 4 that can move up and down to control the cylinder block. Move up and down to realize the lifting of the station of the cylinder block. A worktable 5 that can move back and forth is provided under the lifting raceway 4 to realize the station conversion of the cylinder block; on the workbench 5, there is a workpiece for supporting the cylinder block. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com