Roll-expanding mechanical plug for steam generator heat transfer tube of nuclear power plant and manufacturing method thereof

A technology of a steam generator and a manufacturing method, applied in the field of nuclear power, can solve the problems of affecting the use effect and life of the plug, technical difficulty, corrosion failure, etc., and achieve good installation performance, good corrosion resistance and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

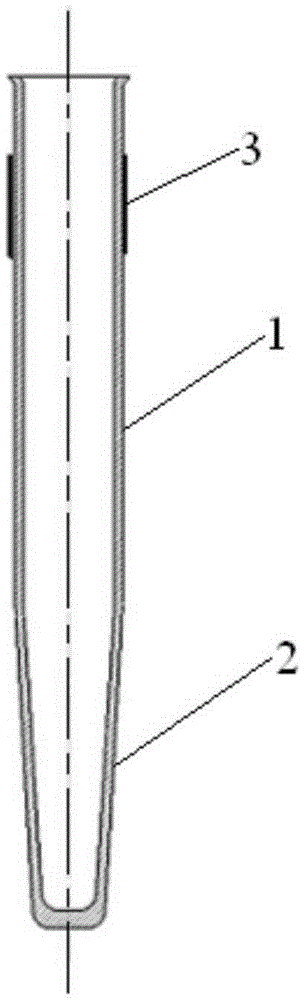

[0042] see figure 1 , a roll-expanding mechanical plug for steam generator heat transfer tubes in nuclear power plants, comprising an upper tube body 1 and a lower tube body 2, the upper tube body 1 and the lower tube body 2 are connected, and the upper end of the upper tube body 1 is open, The lower end of the lower pipe body 2 is closed, and the outer wall of the upper pipe body 1 is sprayed with a plasma sprayed layer 3 , and the plasma sprayed layer 3 is spaced from the top of the upper pipe body 1 .

[0043] In the present invention, the upper pipe body 1 and the lower pipe body 2 have an integral structure, the inner diameter of the upper pipe body 1 is equal from top to bottom, the inner diameter of the lower pipe body 2 gradually decreases from top to bottom, the upper pipe body 1 is a straight line section, and the lower pipe body The main body 2 is a tapered section, the tapered section allows the plug to enter the damaged heat transfer tube more smoothly, and the st...

Embodiment 2

[0071] A roll-expanding mechanical plug for steam generator heat transfer tubes in nuclear power plants, comprising an upper tube body 1 and a lower tube body 2, the upper tube body 1 and the lower tube body 2 are connected and have an integrated structure, and the upper tube body 1 The upper end is open, the lower end of the lower tube body 2 is closed, and a circle of plasma sprayed layer 3 is sprayed on the outer wall of the upper tube body 1. The plasma sprayed layer 3 is spaced from the top of the upper tube body 1. The plasma sprayed layer 3 is along the length direction of the upper tube body 1. The length is 8-10mm; the inner diameter of the upper pipe body 1 is equal from top to bottom, and the inner diameter of the lower pipe body 2 is reduced from top to bottom.

[0072] The manufacturing method of the roll-expanding mechanical plug for the steam generator heat transfer tube of the above-mentioned nuclear power plant:

[0073] 1) Calculate the outer diameter of the ...

Embodiment 3

[0096] A roll-expanding mechanical plug for steam generator heat transfer tubes in nuclear power plants, comprising an upper tube body 1 and a lower tube body 2, the upper tube body 1 and the lower tube body 2 are connected and have an integrated structure, and the upper tube body 1. The upper end is open, the lower end of the lower tube body 2 is closed, and a circle of plasma sprayed layer 3 is sprayed on the outer wall of the upper tube body 1. The plasma sprayed layer 3 is spaced from the top of the upper tube body 1. The plasma sprayed layer 3 is along the length of the upper tube body 1. The length of the direction is 8-10 mm; the inner diameter of the upper pipe body 1 is equal from top to bottom, and the inner diameter of the lower pipe body 2 is reduced from top to bottom.

[0097] The manufacturing method of the roll-expanding mechanical plug for the steam generator heat transfer tube of the above-mentioned nuclear power plant:

[0098] 1) Calculate the outer diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com