Deep well solidification barrel recovery system and its recovery method

A recovery system and deep well technology, applied in chemical instruments and methods, cleaning methods and utensils, load hanging components, etc., can solve the problems of easy falling off of curing barrels, high operational health risks, and low recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

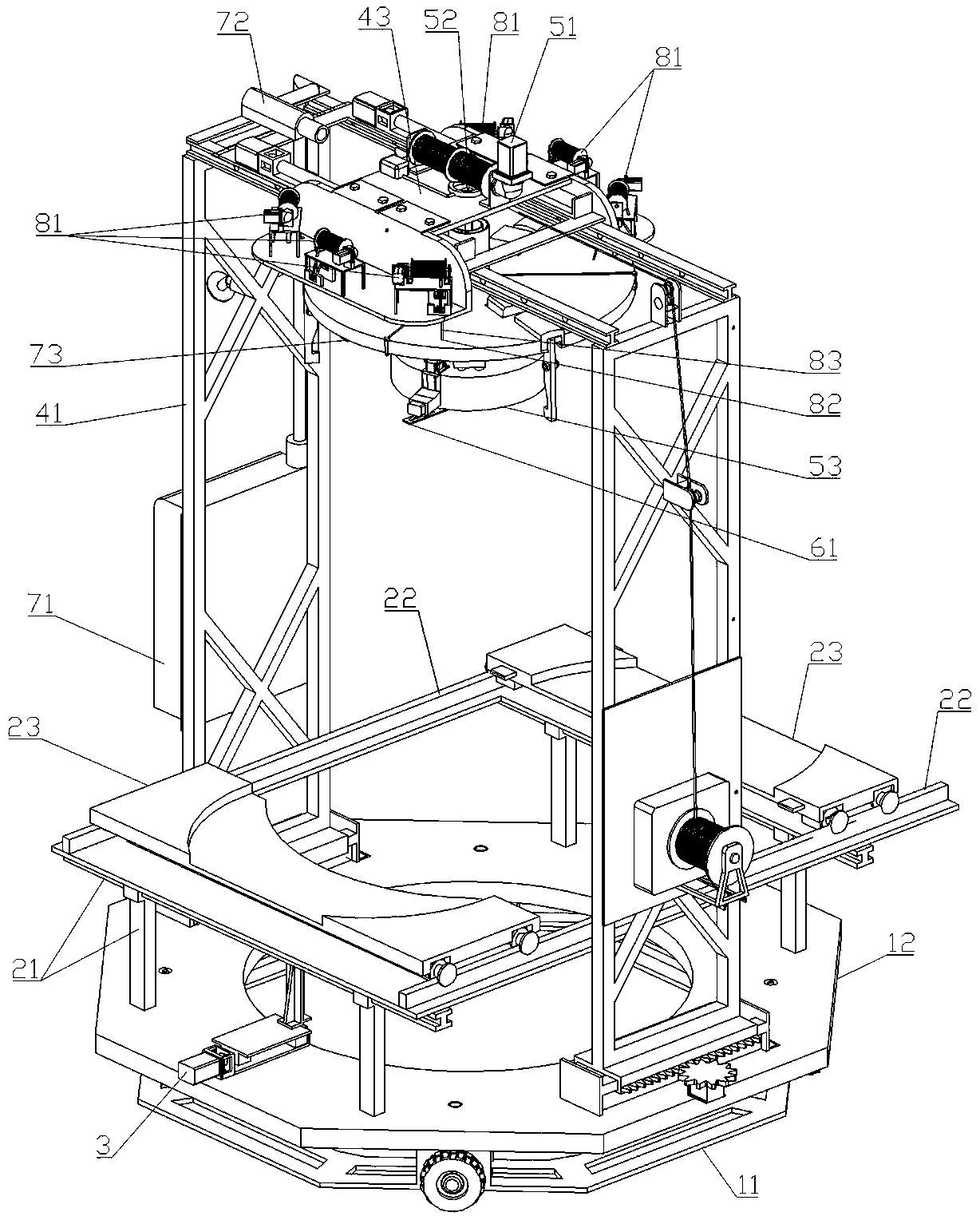

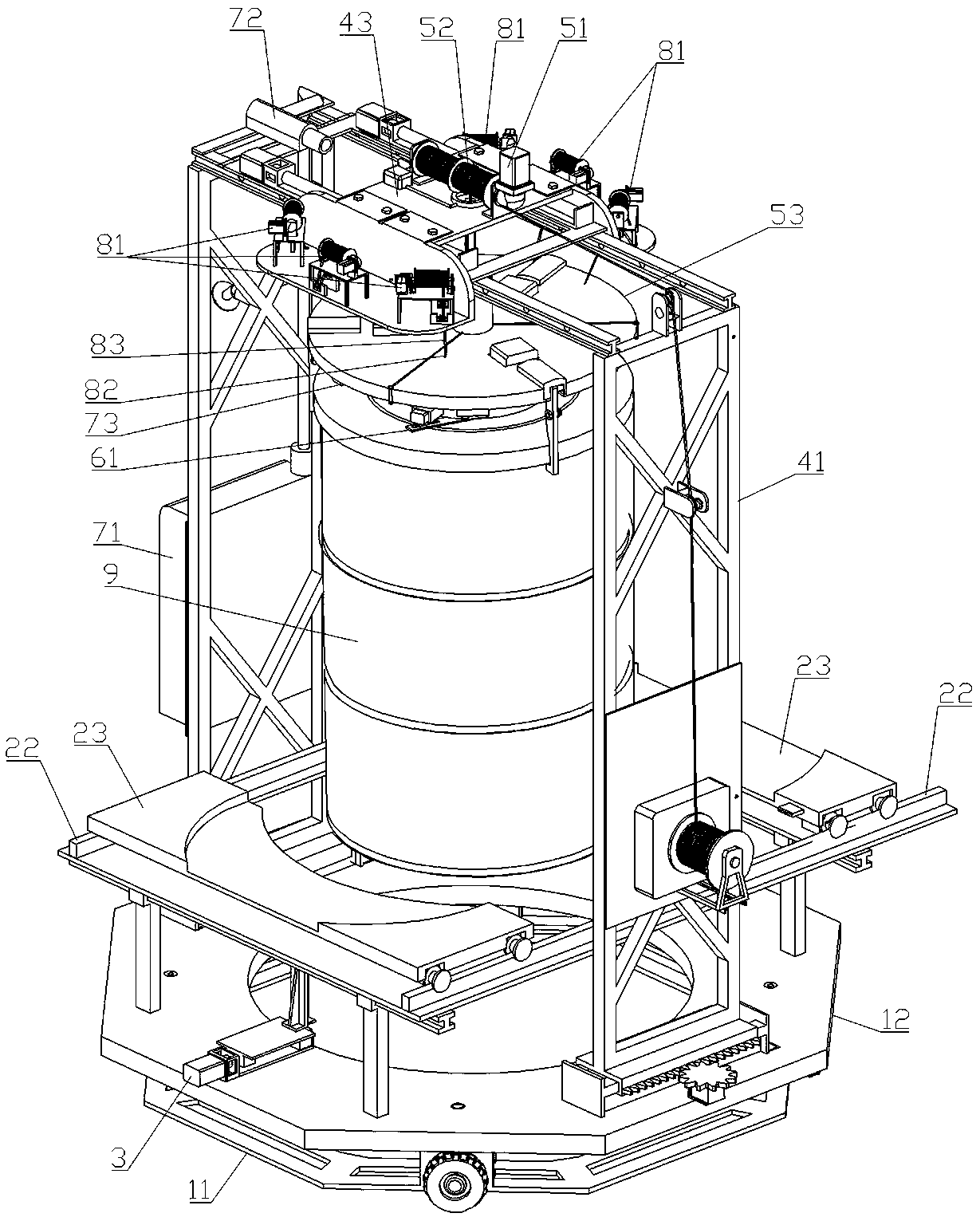

[0085] Such as Figure 1-10 As shown, the lifting system for deep well solidification barrels includes traveling device, horizontal transfer device, logging center device 3, suspension plate shifting mechanism, suspension plate, barrel surface cleaning device, spray dust suppression mechanism, suspension plate deviation adjustment mechanism, and positioning device and control devices.

[0086] The running gear comprises a remote control car 11 and a total load plate 12 . The remote control car 11 includes a car body A and a power source A for driving the car body A to move, and a through hole A is provided in the middle of the remote control car. The total carrying plate 12 is fixedly connected to the upper end of the remote control car 11, and a through hole B is arranged on it, and the through hole B communicates with the through hole A up and down to form a passage 13 for the curing bucket 9 to pass through.

[0087]The horizontal transfer device includes a supporting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com