Vertical shaft storage system for spent fuel of nuclear power station

A technology for spent fuel and nuclear power plants, applied in the field of reactor engineering, to achieve the effects of ensuring integrity, ensuring safe storage, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

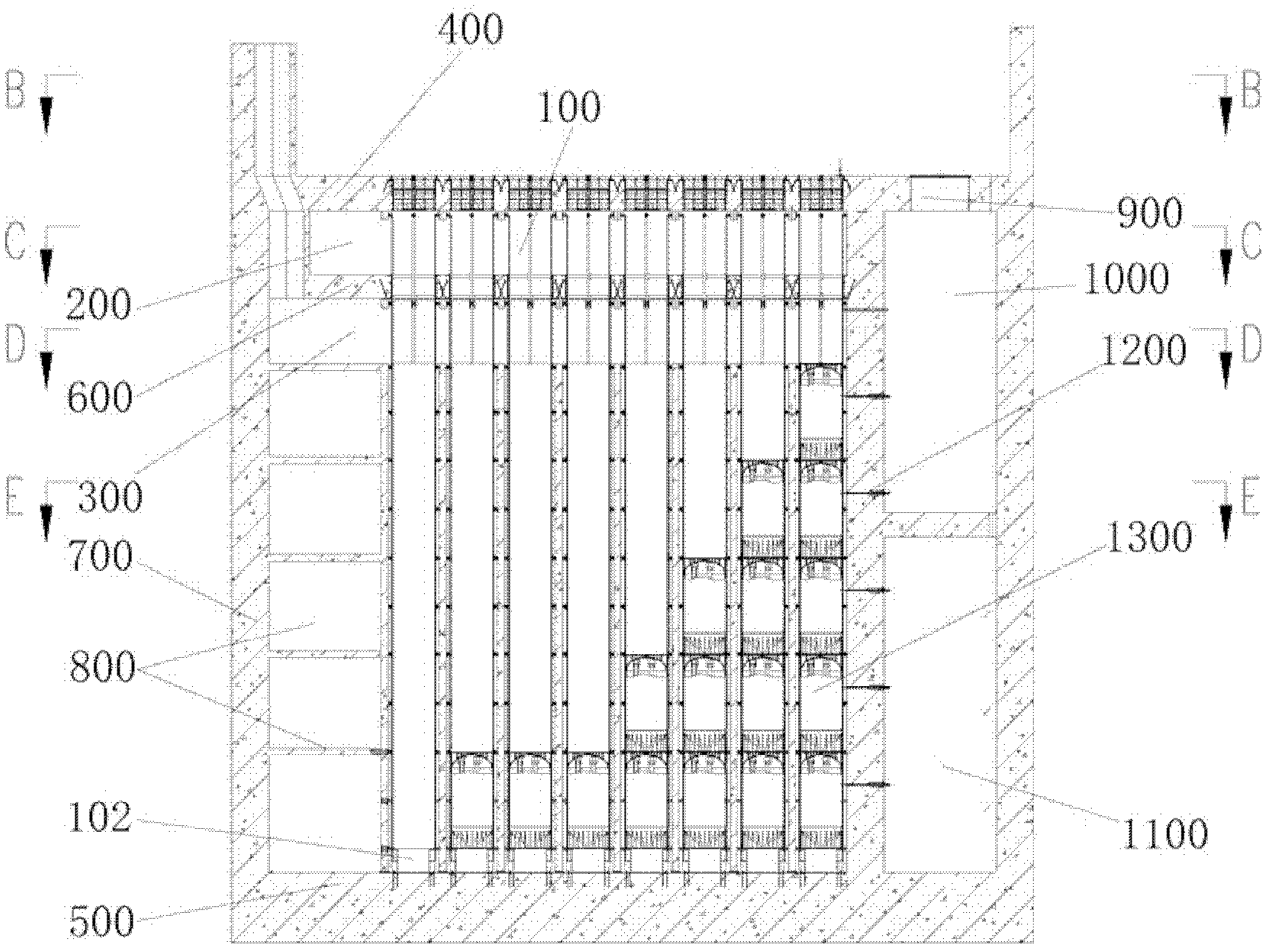

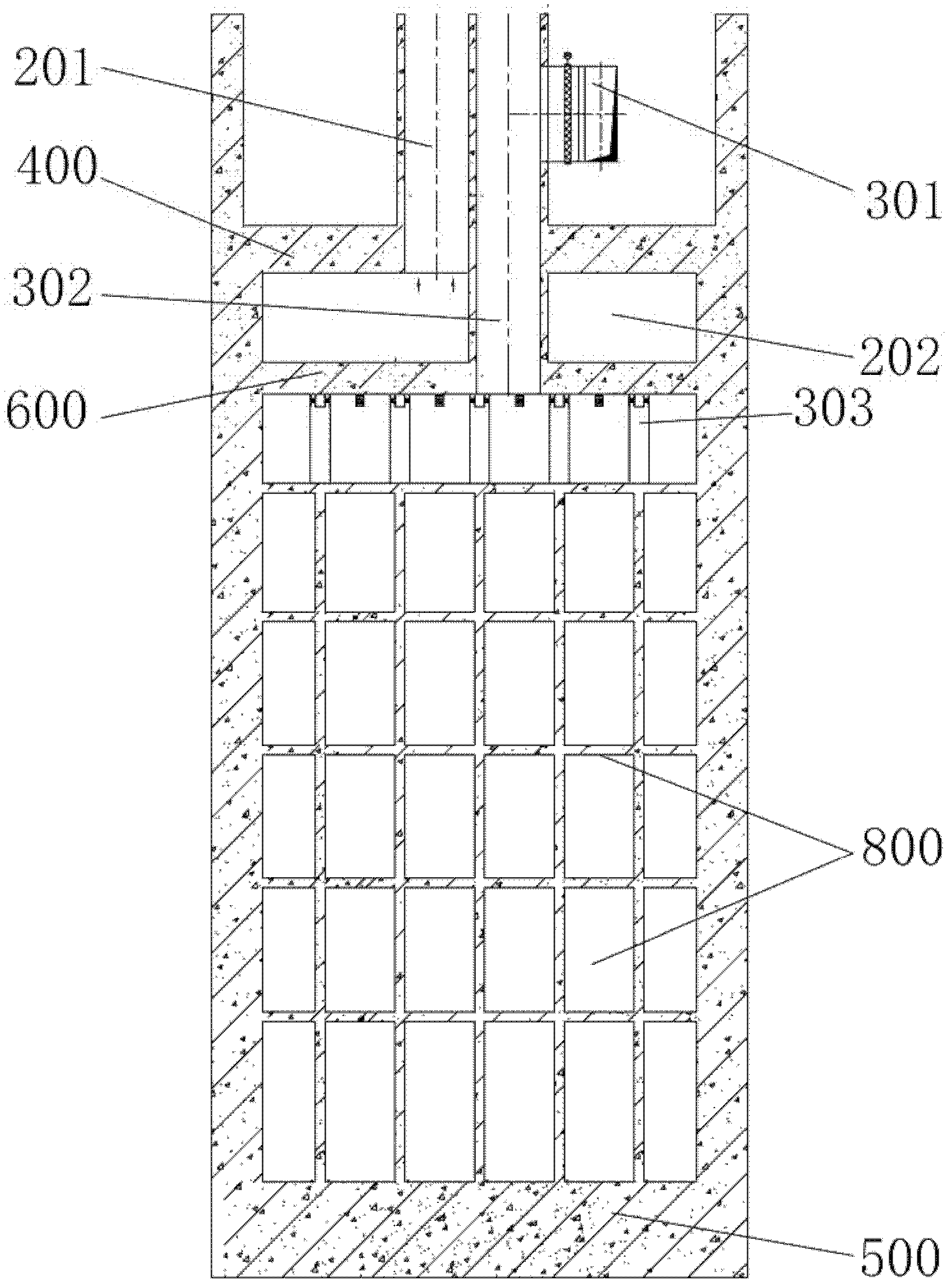

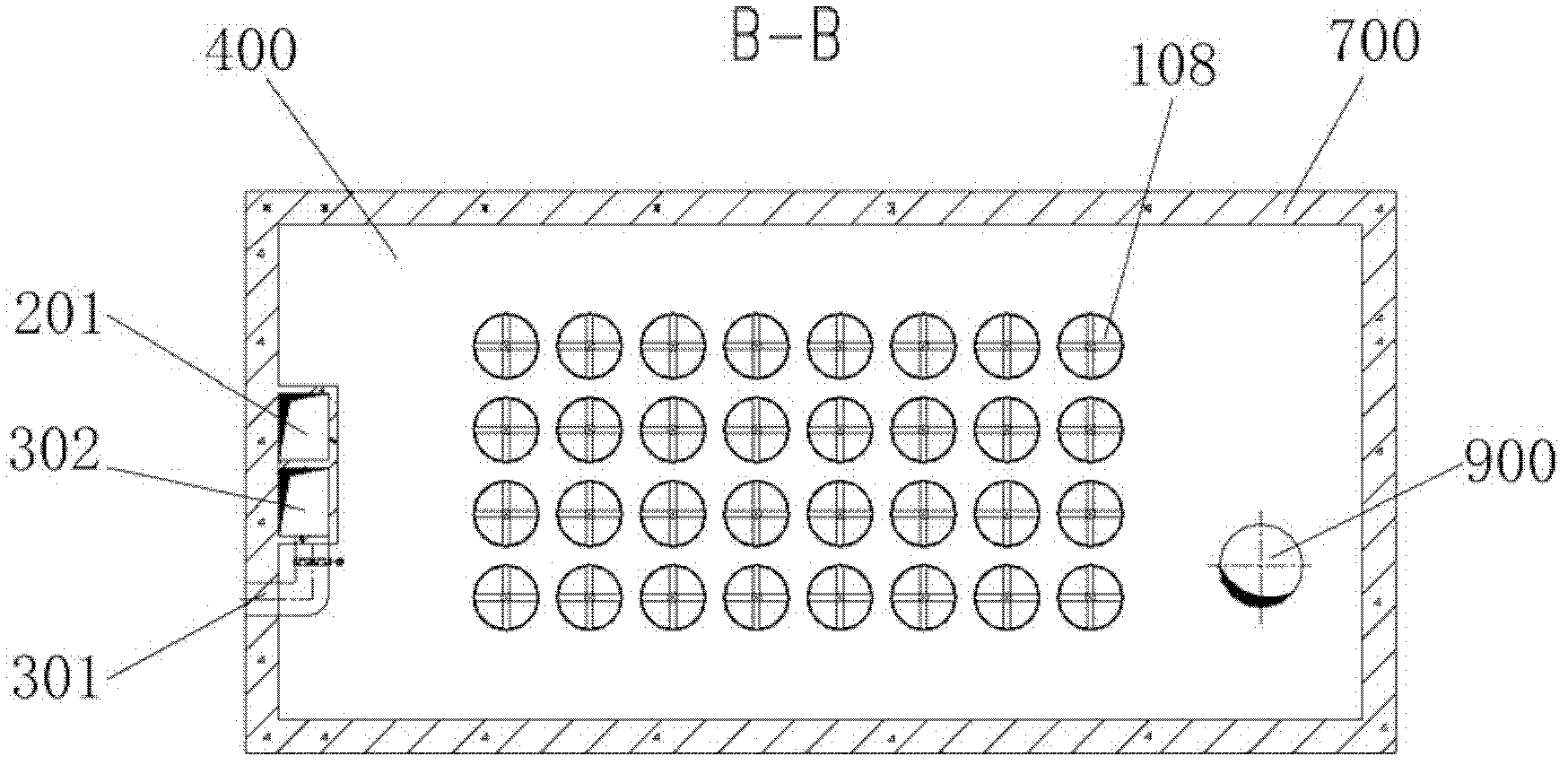

[0033] figure 1 It is a front sectional view of the nuclear power plant spent fuel storage shaft system described in the embodiment of the present invention. Such as figure 1 As shown, the system mainly includes: a shaft array composed of a plurality of shafts 100, a hot air unit 200, a cold air unit 300, a shaft top plate 400, a shaft bottom plate 500, a heat insulation board 600, a shielding wall 700, an anti-seismic support plate 800, a transfer Hole 900 , transfer room 1000 , temperature measurement room 1100 and temperature measurement device 1200 . The spent fuel storage tanks 1300 may be stacked in the shaft 100 .

[0034] The shafts 100 are all arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com