High rib aluminum alloy wallboard manufacturing method

A manufacturing method and technology of aluminum alloy, applied in the direction of sheet/board, building components, etc., to achieve the effect of ensuring manufacturing efficiency and accuracy, ensuring manufacturing accuracy, and ensuring the strength of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

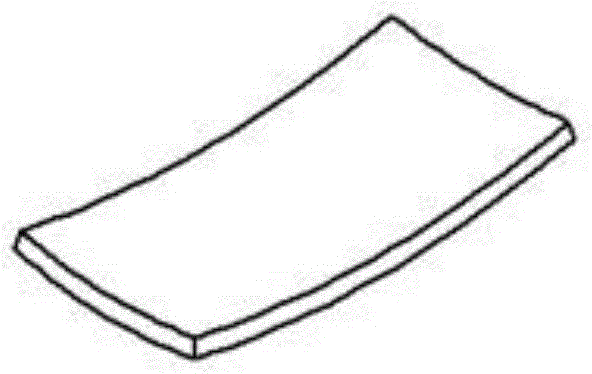

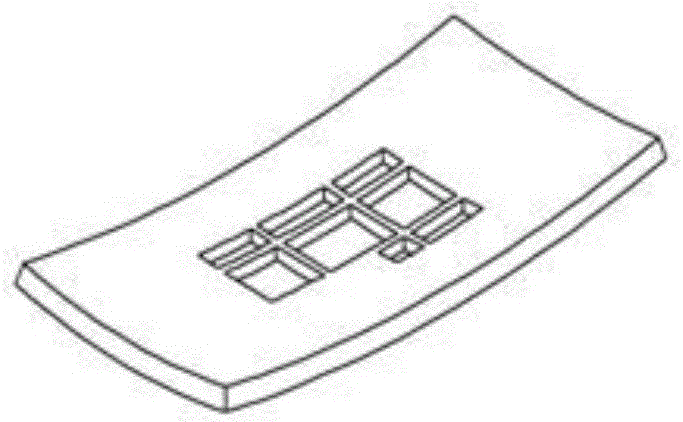

[0033] refer to Figure 1a , Figure 1b , Figure 1c , Figure 1d , Figure 4 ,in Figure 1a — Figure 1d It is a schematic structural diagram of the manufacturing process of high-reinforced aluminum alloy siding, a high-reinforced aluminum alloy siding, which is a double-curvature siding with I-shaped or T-shaped high-reinforced strips. The specific steps of the method are as follows:

[0034] Step 1. Predict the amount of springback according to the target shape, sheet thickness and material parameters of the high-reinforced aluminum alloy panel, obtain the surface data of the upper and lower multi-point molds through calculation, and automatically adjust the upper and lower multi-point molds 1 and 4 Profile;

[0035] The specific steps are as follows:

[0036] 11) Forming preparation process

[0037] According to the size and maximum thickness of the integral wall panel parts to be manufactured, with the machining allowance left in the periphery and thickness directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com