Automatic drilling and detecting machine for lampholder manufacturing

A detection machine and automatic technology, applied in the direction of boring/drilling, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of low efficiency of manual assisted conduction, damage to lamp holder, small size of wire hole 103, etc. Achieve the effect of ensuring preparation efficiency and finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

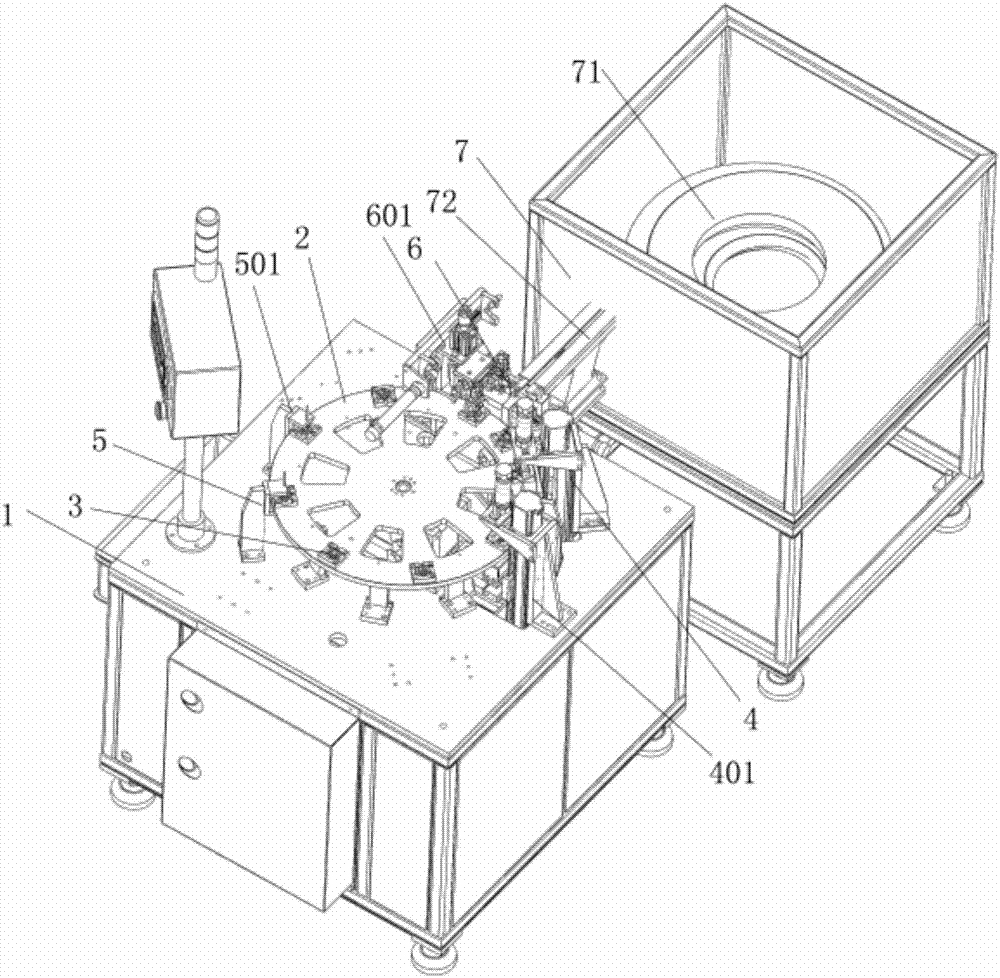

[0047] see figure 1 , 3 , 4, 5, 6, this embodiment shows an automatic drilling inspection machine for lamp holder preparation:

[0048] It includes an index plate 2 rotatably arranged on the frame 1, a number of carriers 3 uniformly arranged on the index plate 2, distributed around the index plate 2 and corresponding to and matched with the carriers 3 The used drilling assembly a 4, drilling assembly b401, detection assembly a 5, and detection assembly b 501;

[0049] In this embodiment, the number of carriers 3 is not limited, and the number of carriers 3 can be set according to production needs;

[0050] The indexing plate 2 is also correspondingly provided with a feeding assembly 7, and the frame 1 is provided with a feeding assembly 6 used in conjunction with the feeding assembly 7 and the carrier 3 provided on the indexing plate 2 respectively, and the frame 1 A blanking assembly 601 used in conjunction with the index plate 2 is also provided.

[0051] The feeding as...

Embodiment 2

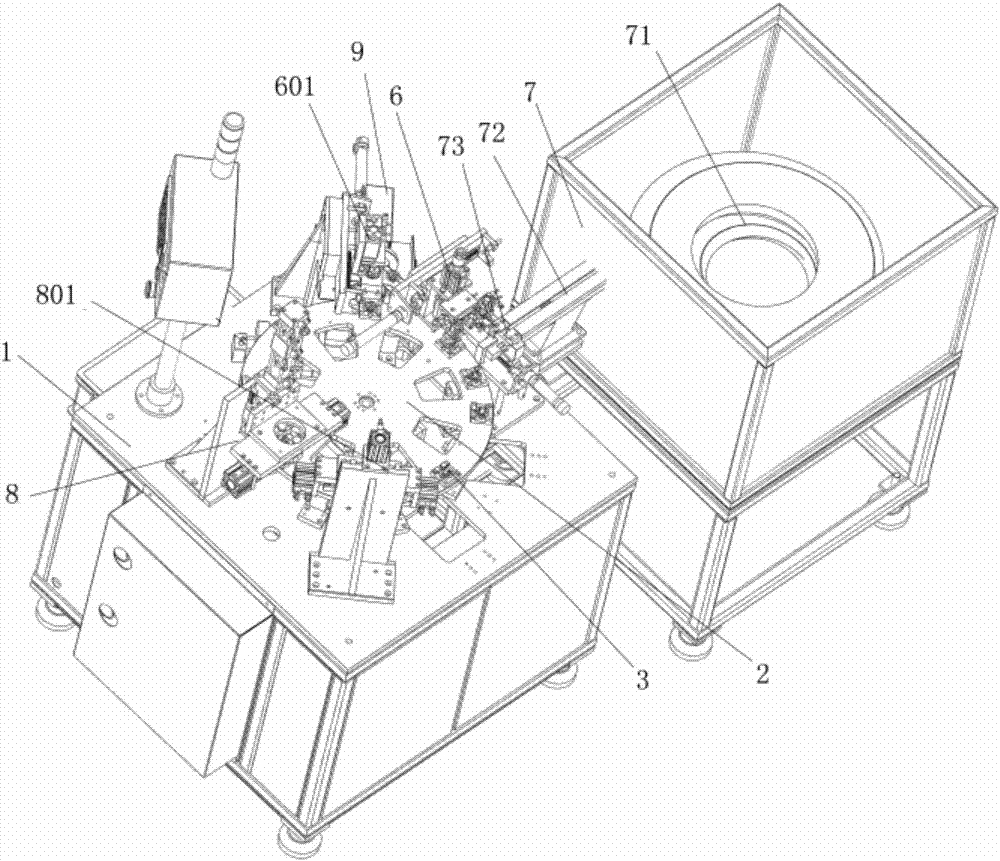

[0066] refer to figure 2 , 3 , 4, 7, 8, this embodiment shows an automatic deburring inspection machine for lamp holder preparation:

[0067] It includes an index plate 2 rotatably arranged on the frame 1, a number of carriers 3 uniformly arranged on the index plate 2, distributed around the index plate 2 and corresponding to and matched with the carriers 3 The deburring assembly a 8 and the deburring assembly b 801 used, the index plate 2 is also provided with the feed assembly 7 correspondingly, and the frame 1 is provided with the carrier 3 that is respectively arranged on the feed assembly 7 and the index plate 2 The feeding assembly 6 used in conjunction with the frame 1 is also provided with the unloading assembly 601 used in conjunction with the index plate 2 and the detection assembly c 9 used in conjunction with the unloading assembly 601 .

[0068] In this embodiment, the number of carriers 3 is not limited, and the number of carriers 3 can be set according to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com