Facility for producing piercing plug

一种制造设备、轧制机的技术,应用在穿孔轧制用顶头的制造设备领域,能够解决覆膜剥离等问题,达到提高顶头寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

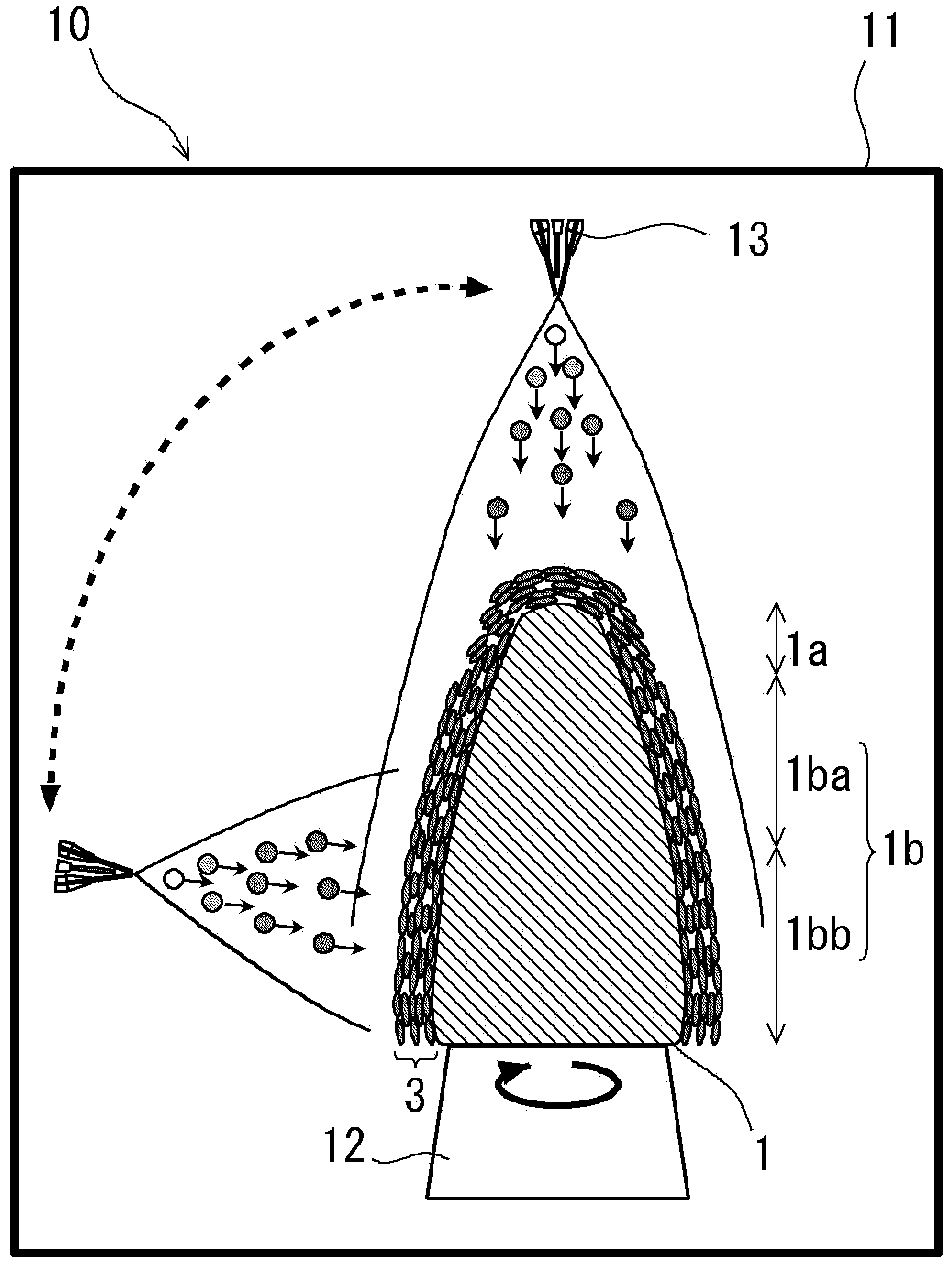

[0069] Figure 7It is a schematic diagram showing the manufacturing equipment of the plug with an arc sprayed coating as the first embodiment of the present invention. The manufacturing facility of the first embodiment shown in the same figure uses the figure 1 , figure 2 The configurations of the manufacturing facilities of Conventional Examples 1 and 2 shown are based on it, and redundant descriptions are appropriately omitted.

[0070] Such as Figure 7 As shown, the manufacturing facility of this embodiment includes an arc spraying device 10 and a shot blasting device (not shown) arranged in the preceding stage of the arc spraying device 10 . The shot blasting device is the same as that of the manufacturing facilities of the above-mentioned conventional example 1 and example 2.

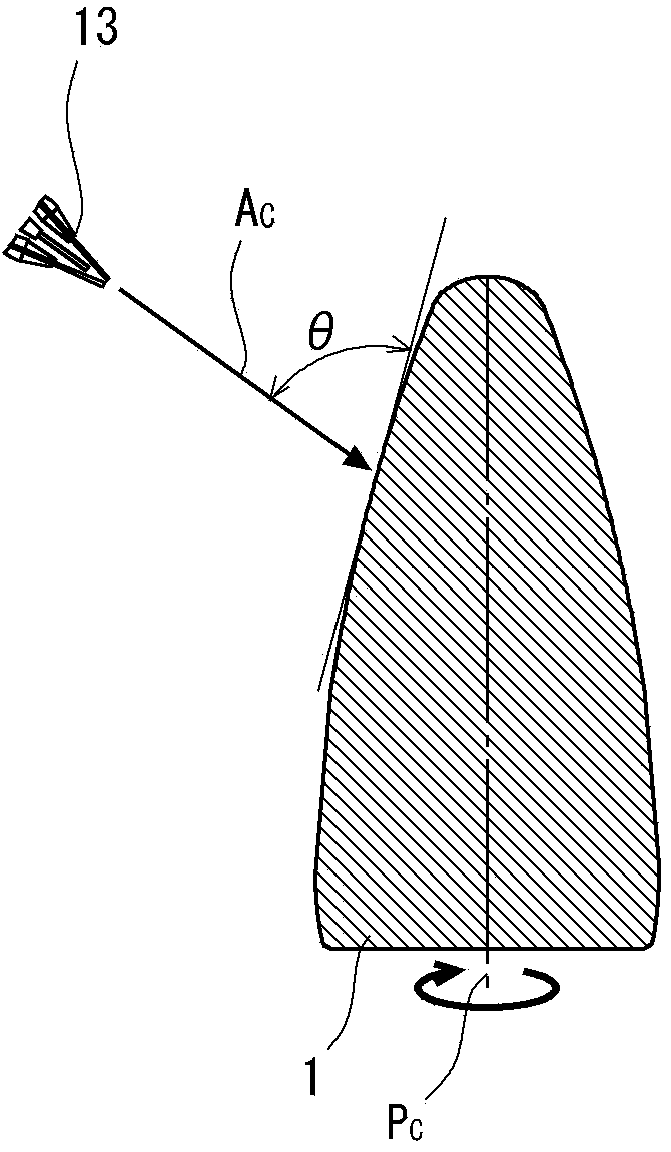

[0071] In this embodiment, the outer surface of the base material of the plug 1 is divided into two regions along the axial direction of the plug 1 . Figure 7 An example of being divided i...

no. 2 Embodiment approach >

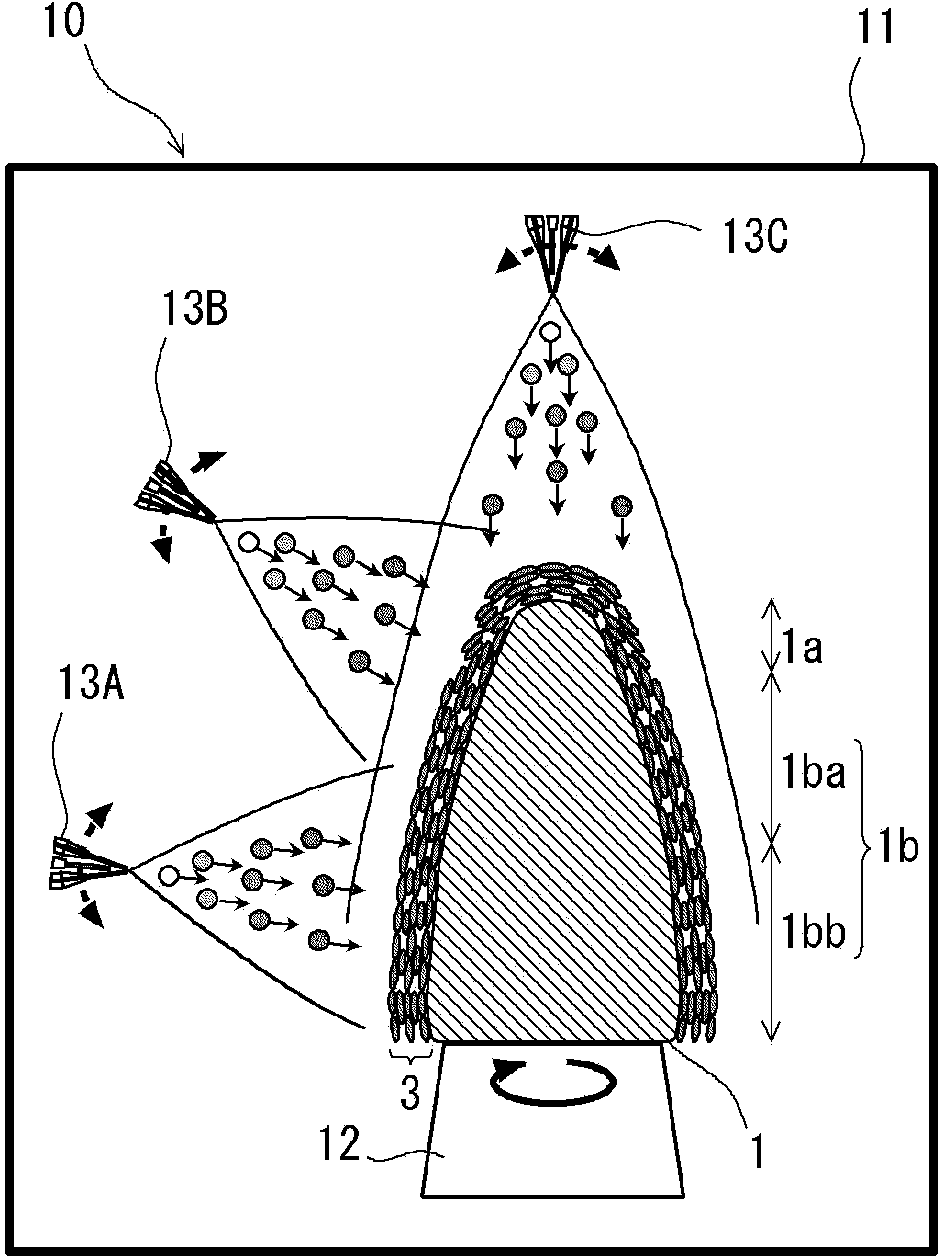

[0085] Figure 8 It is a schematic diagram showing the manufacturing equipment of the plug with an arc sprayed coating as the second embodiment of the present invention. The manufacturing equipment of the second embodiment shown in the same figure and the Figure 7 Compared with the manufacturing facility of the first embodiment shown, the configuration differs in the following points.

[0086] The manufacturing facility of this embodiment increases the number of regions obtained by dividing the outer surface of the base material of the plug 1 . That is, in this embodiment, the base material outer surface of the plug 1 is divided into three regions along the axial direction of the plug 1 . Figure 8 An example of being divided into a tip end portion 1a, a main body front half 1ba, and a main body rear half 1bb is shown in .

[0087] The arc spraying apparatus 10 in this embodiment has three spraying chambers 11A, 11B, and 11C for forming the coating 3 , the number of which ...

Embodiment

[0100] In order to confirm the effect of the present invention, a test was performed in which a plug for piercing and rolling was manufactured, and the manufactured plug was mounted on a piercer to perform piercing and rolling. The test conditions are as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com