An automatic batching device and batching method

An automatic batching and feeding device technology, applied in mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve problems such as scattering, large errors, and affecting printing and dyeing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

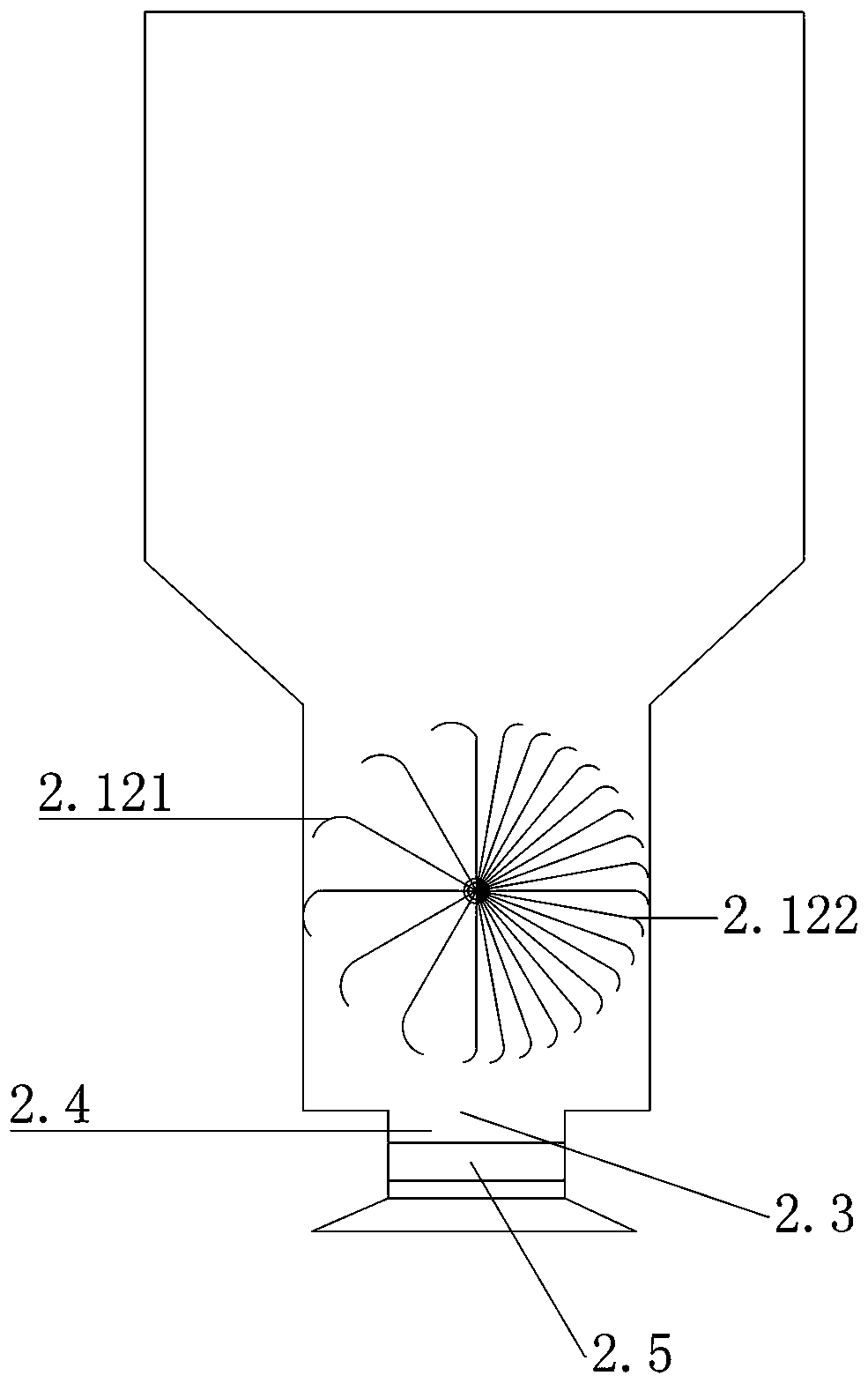

[0022] refer to Figure 1-3As shown, an automatic batching device of the present embodiment includes a liquid feeding device, a solid powder feeding device and a mixing device, the liquid feeding device includes a liquid storage tank 1, and the liquid storage tank 1 is provided with a liquid level gauge 1.1 and a The liquid outlet 1.2, the liquid outlet 1.2 is connected with the liquid outlet pipe 1.3, the liquid outlet pipe 1.3 is provided with a flow control meter 1.4 and a booster pump 1.5, through the interaction of the liquid level gauge 1.1, the flow control meter 1.4 and the booster pump 1.5 Cooperate to realize the quantitative feeding of the liquid; the solid powder feeding device includes a powder storage tank 2 and a weighing device 3, the width of the lower end of the powder storage tank 2 is smaller than that of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com