Procambarus-clarkii environment-friendly sinking puffing feed and preparing method

A technology of Crayfish and extruded feed, applied in the field of feed, can solve the problems of unsatisfactory cultivation specifications, easy to cause water pollution, low survival rate of cultivation, etc., so as to improve feed utilization efficiency, improve digestion and utilization efficiency, and reduce ammonia nitrogen. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

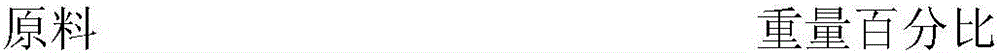

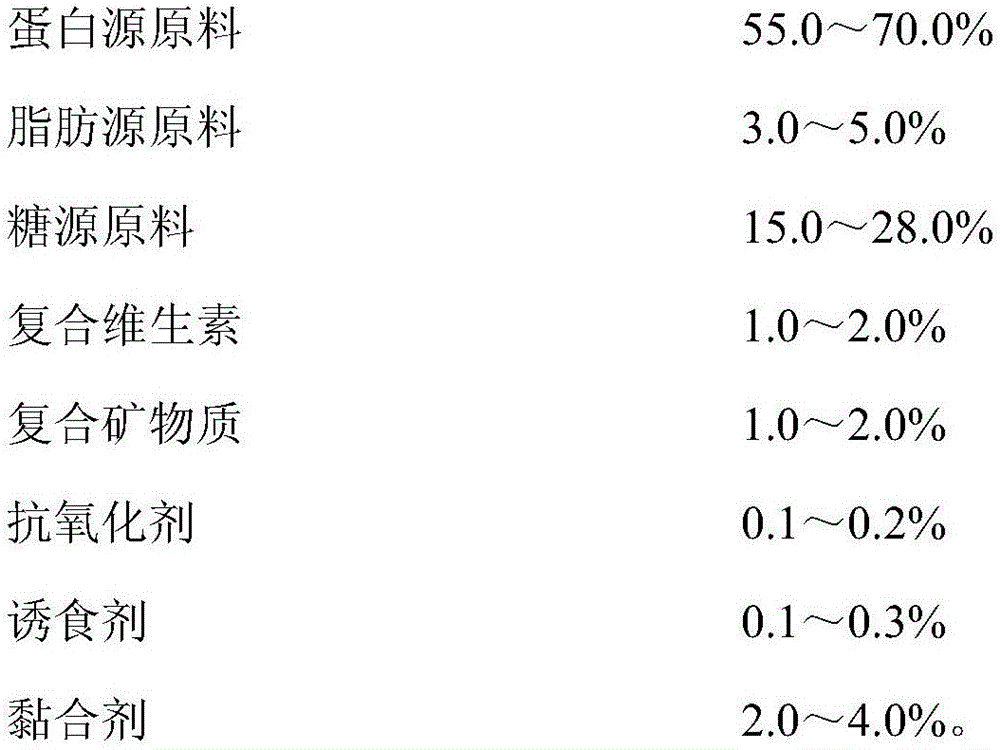

Method used

Image

Examples

Embodiment 1

[0038] According to formula 1 shown in Table 1, extruded pellet feed and ordinary ring die pellet feed were prepared, and 4.17 to 8.34 g of Procambarus clarkii were fed for 40 days under the aquaculture water environment of 17 to 25 ° C. The feed coefficient of the extruded feed group was 0.96, and the specific Weight gain rate (SGR,%d ~1 ) 4.88, weight gain rate (WG,%) 604.83%, survival rate 89.17%; common ring die pellet feed group feed coefficient 1.38, specific weight gain rate (SGR,%d ~1 ) 4.46, weight gain rate (WG, %) 496.31%, survival rate 77.92%, each parameter extruded feed breeding effect is significantly higher than ordinary ring die pellet feed.

[0039] The preparation method of extruded pellet feed is:

[0040] 1) Weigh the feed raw materials in said parts by weight, stir and mix all the raw materials separately, grind the powdery raw materials (protein source raw materials, sugar source raw materials, compound vitamins, compound mineral salts, antioxidants and...

Embodiment 2

[0044] According to formula 2 shown in Table 1, extruded pellet feed and ordinary ring die pellet feed were prepared, and 4.17-8.34 g of Procambarus clarkii were fed for 40 days under the culture water environment of 17-25°C. The feed coefficient of the extruded feed group was 1.04, and the specific Weight gain rate (SGR,%d ~1 ) 4.76, weight gain rate (WG,%) 572.52%, survival rate 90.83%; common ring die pellet feed group feed coefficient 1.46, specific weight gain rate (SGR,%d ~1 ) 4.42, weight gain rate (WG, %) 486.76%, survival rate 74.58%, each parameter puffed feed breeding effect is significantly higher than ordinary ring die pellet feed.

[0045] The preparation method of the expanded pellet feed and the ring die pellet feed is the same as in Example 1.

Embodiment 3

[0047] According to formula 3 shown in Table 1, extruded pellet feed and ordinary ring die pellet feed were prepared, and 4.17-8.34 g of Procambarus clarkii were fed for 40 days under the aquaculture water environment of 17-25 ° C. The feed coefficient of the extruded feed group was 1.06, and the specific Weight gain rate (SGR,%d ~1 ) 4.67, weight gain rate (WG,%) 547.27%, survival rate 91.25%; common ring die pellet feed group feed coefficient 1.45, specific weight gain rate (SGR,%d ~1 ) 4.29, weight gain rate (WG, %) 457.18%, survival rate 73.75%, each parameter extruded feed breeding effect is significantly higher than ordinary ring die pellet feed.

[0048] The preparation method of the expanded pellet feed and the ring die pellet feed is the same as in Example 1.

[0049] Feed coefficient ratio (FCR) = feed amount / (final body weight ~ initial body weight);

[0050] Specific growth rate (specific growth ratio, SGR) = (ln final body weight - ln initial body weight) / days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com