Common-mode inductor applying high-stability ultra-crystalline magnetic core and manufacturing method of common-mode inductor

A common-mode inductance and high-stability technology, which is applied in the direction of inductance with magnetic core, inductance/transformer/magnet manufacturing, fixed inductors, etc., can solve the problem of poor temperature stability, weak electromagnetic shielding ability, and stable temperature Poor performance and other problems, to achieve the effect of low saturation magnetic induction, excellent heat dissipation performance, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

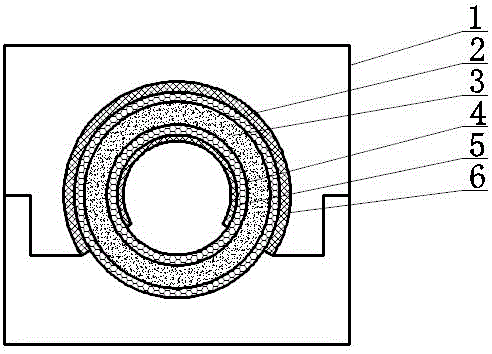

[0034] A common-mode inductor that uses a high-stability ultrafine-crystalline magnetic core, using a special ultrafine-crystalline magnetic core 3, using a specific ceramic skeleton 2, applying an aluminum alloy fully-enclosed shield 1, and applying heat conduction Insulating material 4; the ultramicrocrystalline magnetic core 3 is sealed in the ceramic frame 2 by epoxy resin, the surface of the winding 6 and the gap between the winding 6 and the ceramic frame 2 are filled with a thermally conductive insulating material 4, and the thermally conductive insulating material 4 is also packaged with a ring Oxygen resin; aluminum alloy shielding cover 1 sets the entire neutralization transformer except the shielding cover 1, and adopts a fully enclosed structure.

[0035] The method for manufacturing a common-mode inductor using a high-stability ultramicrocrystalline magnetic core includes the following steps:

[0036] 1) Selection and preparation of various components

[0037] ①T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com