A cold-resistant aluminum alloy cable

A technology of aluminum alloy and aluminum alloy conductors, which is applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of cable icing, influence, and increase in cable weight, and achieve the effects of simple structure, avoiding accumulation, and little structural change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

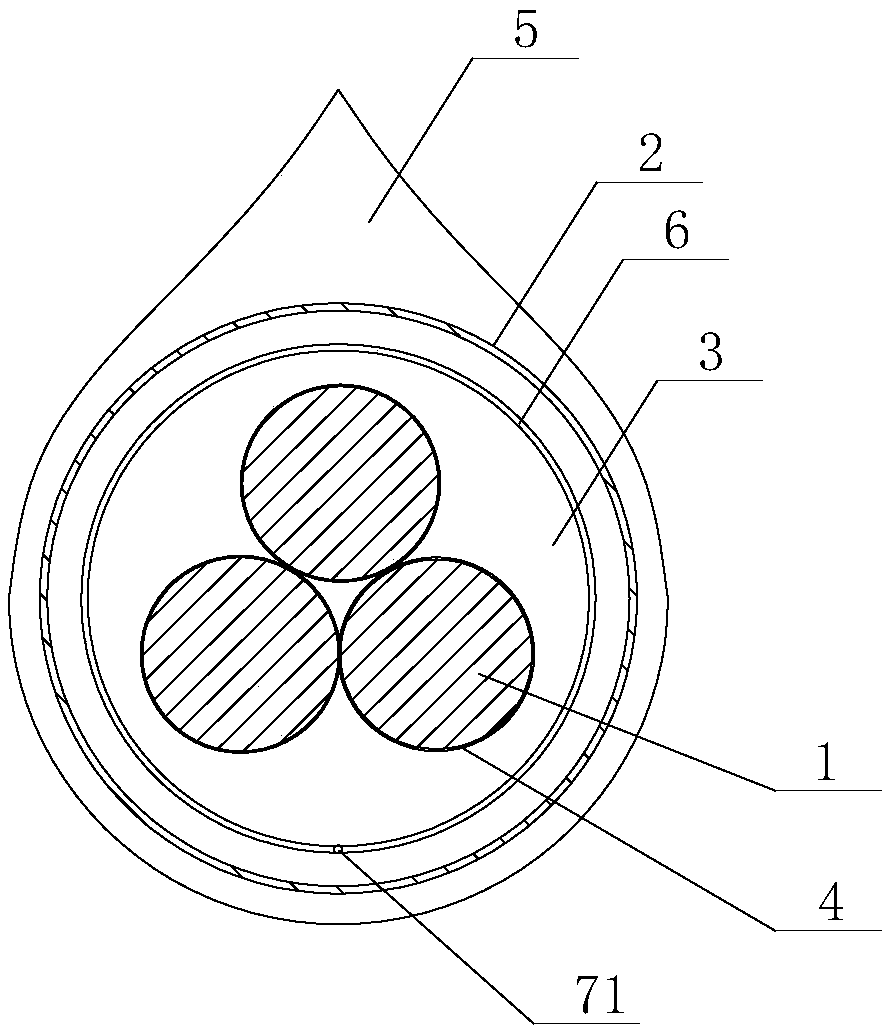

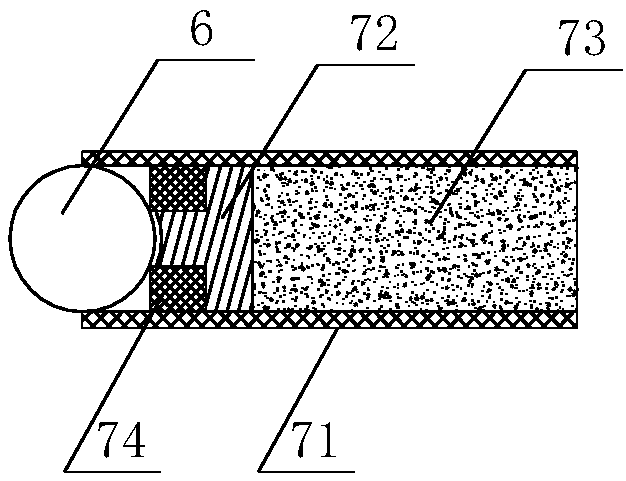

[0017] Such as figure 1 , figure 2 with image 3 As shown: the present invention provides a cold-resistant aluminum alloy cable, which includes three aluminum alloy wires 1 arranged in an equilateral triangle, a shielding layer 2 coated on the outside of the aluminum alloy wires 1, and an aluminum alloy wire 1 and the shielding layer filled 2 The filling layer 3 in the gap, the shielding layer 2 is made of steel strip, the filling layer 3 is made of asbestos fiber filler, the outer surface of the aluminum alloy wire 1 is wrapped with an insulating layer 4, the material of the insulating layer 4 is polyvinyl chloride, the thickness is not greater than 1mm, and the shielding The outer side of the layer 2 is provided with an insulating outer layer 5, the material of the insulating outer layer 5 is polyvinyl chloride, and the cross section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com