Method for increasing fermentation unit of acarbose

A technology of acarbose and unit, which is applied in the field of medicine and can solve the problems of uncontrolled light duration and intensity and low fermentation unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 light condition test

[0016] (1) Seed bottle seed culture

[0017] Each cultured fresh slant was inoculated into a 500m Erlenmeyer flask with a seed medium loading of 20%, and was shaken on a shaker at a speed of 250r / min for 48 hours at a temperature of 27°C to obtain a shaker flask seed solution;

[0018] (2) Shake flask fermentation

[0019] Connect the cultured mother bottle seed solution to a 500m1 Erlenmeyer flask with a fermentation medium loading of 10% according to a 15% inoculum amount, and shake and cultivate at a speed of 250r / min for 168h at a temperature of 27°C;

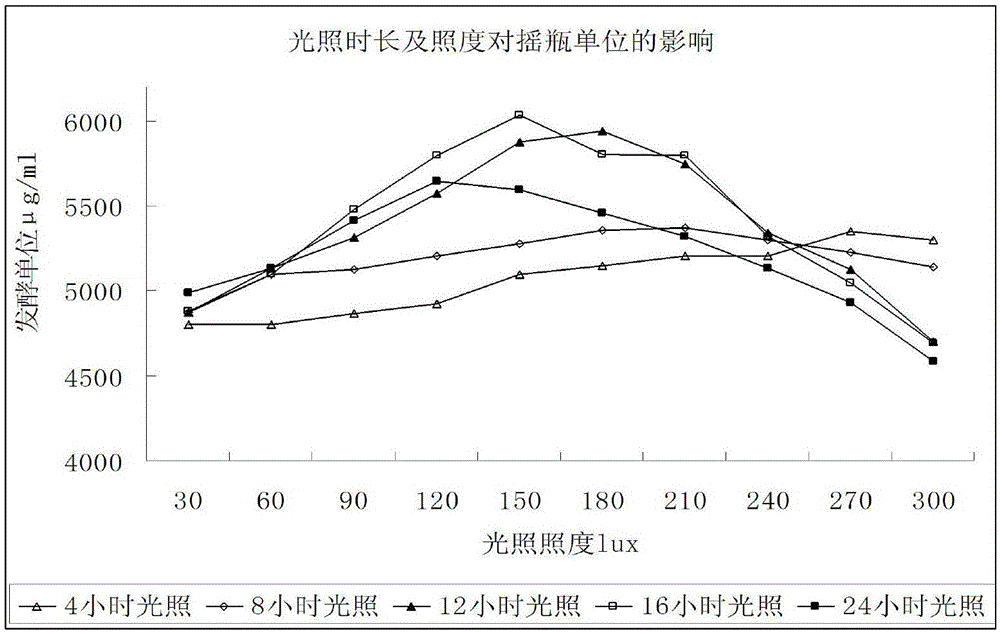

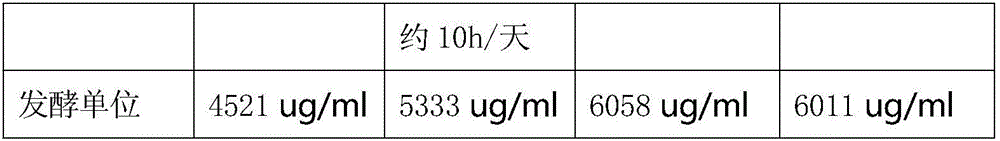

[0020] See the experimental results figure 1 ,Depend on figure 1 It can be seen that during the cultivation of Actinoplanes sp. on the slant, incandescent lamps are used as the light source, the illumination time is controlled at 12-20h / day, and the illumination is 120-180lux, and the best is 12-16h / day, and the illumination is 150-180lux.

Embodiment 2

[0021] Embodiment 2 comparative experiment

[0022] Prepare slant medium, and its substratum is composed as follows: sucrose 30g / L, peptone 5g / L, KC10.5g / L, KH2P041.0g / L, L-tyrosine 1g / L, MgS040.5g / L, agar 20g / L, the solvent is water, and the initial pH is 7.0. Sterilize at 121°C for 30 minutes.

[0023] Prepare seed bottle culture medium, the culture medium composition is as follows: starch 10g / L, soybean cake powder 10g / L, CaCO 3 2g / L, glycerin 20g / L, solvent is water, initial pH is 7.0. Sterilize at 121°C for 30 minutes.

[0024] Prepare fermentation shake flask culture medium, the culture medium composition is as follows: maltose 60g / L, glucose 20g / L, soybean cake powder 15g / L, FeCl 3 0.2g / L, CaCl 2 2g / L, CaCO 3 4g / L, sodium glutamate 2g / L, KH2P04 1g / L, the solvent is water and the initial pH is 7.0. Sterilize at 121°C for 30 minutes.

[0025] Slant strain preparation: Aseptically transfer the low-temperature glycerol tube strain to fresh, sterile slant medium. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com