Silicon-based composite and preparation method thereof and lithium ion battery with silicon-based composite

A technology of silicon-based composite materials and lithium-ion batteries, applied in the field of electrochemistry, can solve problems such as unfavorable industrial production, affecting practical applications, and cumbersome preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A preparation method for a silicon-based composite negative electrode material for a lithium ion battery, comprising the steps of:

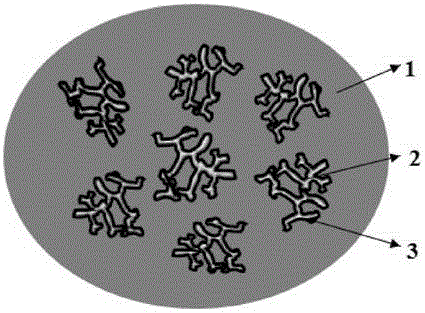

[0081] (1) Mix SiO with a median particle size of 50nm and metal magnesium powder of 5μm at a mass ratio of 1:1, put it into a VC machine, set the frequency to 20HZ, and set the time to 1h. Then put the mixed material in a heat treatment furnace, pass in argon, raise the temperature to 650°C, react for 3h, soak the reacted product in 1mol / L HCl solution for 2h, centrifuge, suction filter, and dry at 80°C Dendritic nano-silicon is obtained with an average particle size of 35 nm.

[0082] (2) Put the dendritic nano-silicon in the rotary furnace, feed methane gas, the flow rate is 0.3L / min, control the rotational speed of the rotary furnace to 0.8rpm, then raise the temperature to 800°C, keep it for 3h, and obtain the carbon-coated dendritic nano-silicon silicon.

[0083] (3) Disperse carbon-coated dendritic nano-silicon, mix it with phenol...

Embodiment 2

[0091] A preparation method for a lithium-ion battery nano-silicon-based composite negative electrode material, comprising the steps of:

[0092] (1) Mix SiO with a median particle size of 50nm and metal sodium powder of 10μm at a mass ratio of 1:1, put it into a VC machine, set the frequency to 20HZ, and set the time to 1h. Then put the mixed material in a heat treatment furnace, pass in argon, raise the temperature to 650°C, react for 3h, soak the reacted product in 1mol / L HCl solution for 2h, centrifuge, suction filter, and dry at 80°C Dendritic nano-silicon is obtained with an average particle size of 50 nm.

[0093] (2) Put the dendritic nano-silicon in the rotary furnace, feed methane gas, the flow rate is 0.3L / min, control the rotational speed of the rotary furnace to 0.8rpm, then raise the temperature to 800°C, keep it for 3h, and obtain the carbon-coated dendritic nano-silicon silicon.

[0094] (3) Disperse carbon-coated dendritic nano-silicon, mix it with pitch pow...

Embodiment 3

[0097] A preparation method for a lithium-ion battery nano-silicon-based composite negative electrode material, comprising the steps of:

[0098] (1) SiO with a median particle size of 20nm 2 Mix it with 20μm metal magnesium powder at a mass ratio of 1:1, put it into a VC machine, set the frequency to 20HZ, and set the time to 1h. Then put the mixed material in a heat treatment furnace, pass in argon, raise the temperature to 700°C, react for 3h, soak the reacted product in 0.5mol / L HCl solution for 2h, centrifuge, suction filter, and bake at 80°C Dry to obtain dendritic nano-silicon with an average particle size of 36nm.

[0099] (2) Place dendritic nano-silicon in a rotary furnace, feed acetylene gas at a flow rate of 0.3L / min, control the rotational speed of the rotary furnace at 0.8rpm, then raise the temperature to 800°C, and keep it for 3h to obtain carbon-coated dendritic nano-silicon silicon.

[0100] (3) Disperse the carbon-coated dendritic nano-silicon, mix it wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com