BiIo sensitized BiIO/TiO2 composite electrode material, preparation method and application thereof

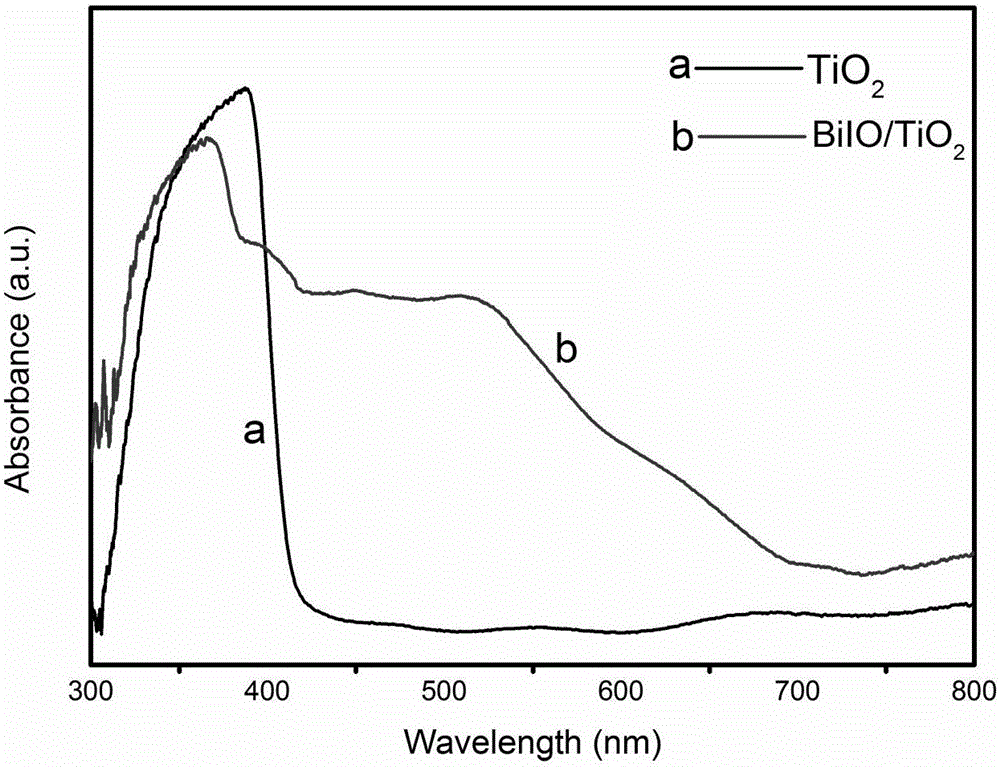

A composite electrode, mixed solution technology, applied in nanotechnology for materials and surface science, semiconductor/solid-state device manufacturing, circuits, etc. High, low visible light absorption efficiency, etc., to achieve practical and commercialization, broaden the spectral response range, and improve the photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] (1) BiIO / TiO sensitized by BiIO 2 The preparation method of the composite electrode material is as follows:

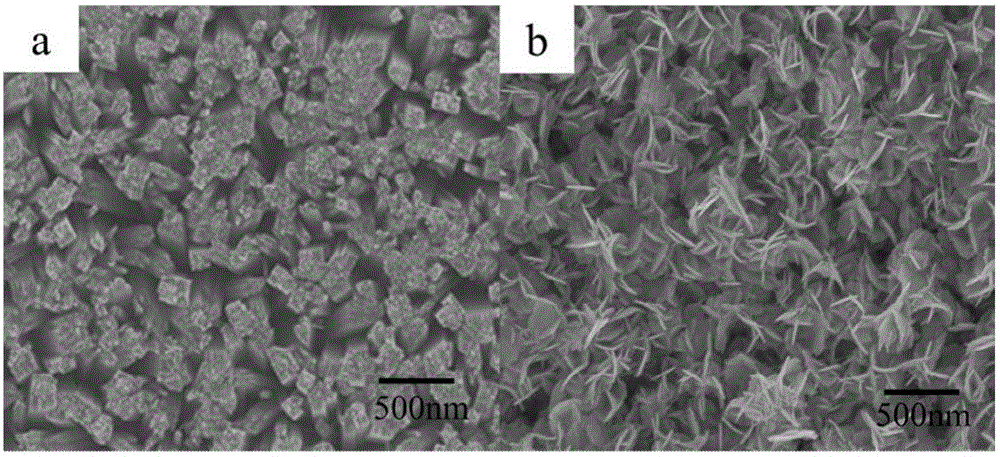

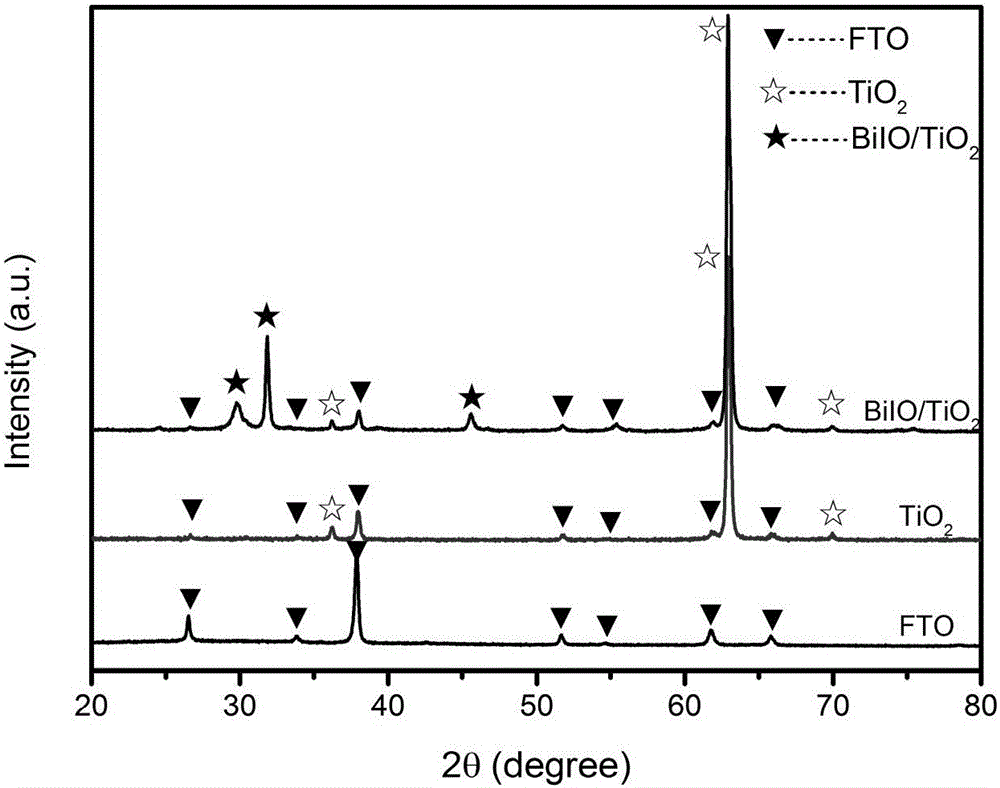

[0026] 1) TiO 2 Preparation of the nanorod array: 30 mL of hydrochloric acid with a concentration of 18% by volume and 0.5 mL of tetra-n-butyl titanate with a concentration of 98% by mass were mixed together, and stirred for 5 minutes to obtain a mixed solution. Transfer fluorine-doped tin dioxide conductive glass (its square resistance is 20 ohms) and 8mL of the above mixed solution to a high-pressure reactor (its inner lining volume is 15mL), and lean the conductive surface of the conductive glass against the inner lining of the reactor , under the condition of 150℃, hydrothermal reaction for 20h, cooled to room temperature, rinsed with deionized water, dried, and the obtained intermediate product was named TiO 2 nanorod arrays.

[0027] 2) BiIO sensitization treatment: After dispersing 0.002mol of bismuth nitrate pentahydrate into 20mL of ethylene glycol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com