Photoetching vacuum clamp for perforated ceramic chip of thin-film circuit

A thin-film circuit and vacuum clamp technology, applied in microlithography exposure equipment, optics, optomechanical equipment, etc., can solve the vacuum adsorption failure, affect the dimensional stability of high-frequency circuits, and cannot complete the matching of substrate and lithography patterns. To solve problems such as position work, to achieve the effect of convenient clamping, convenient gas path and sealing processing, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

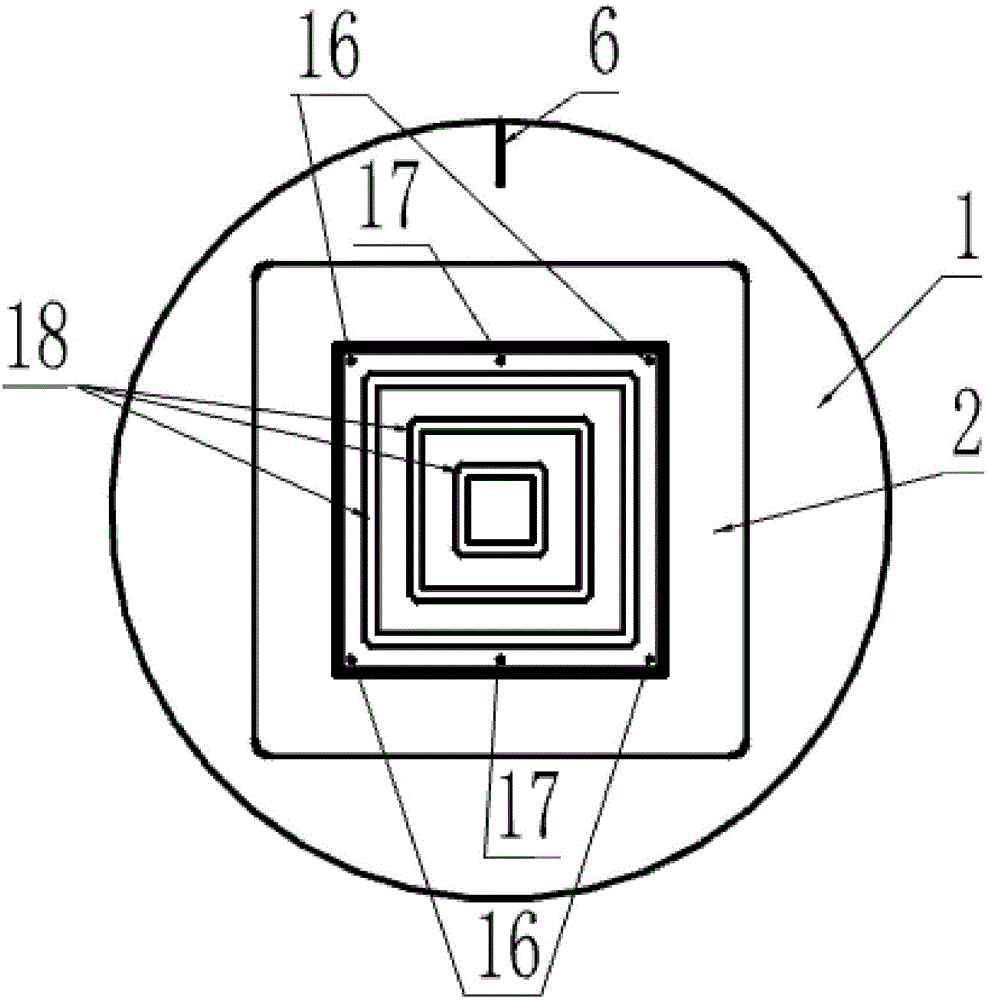

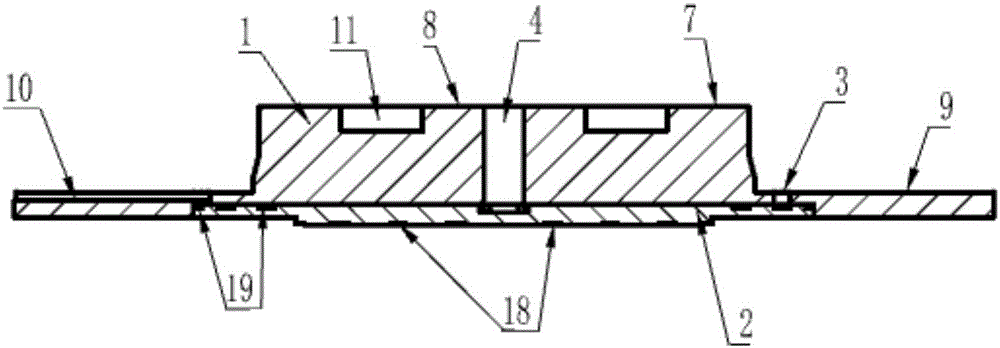

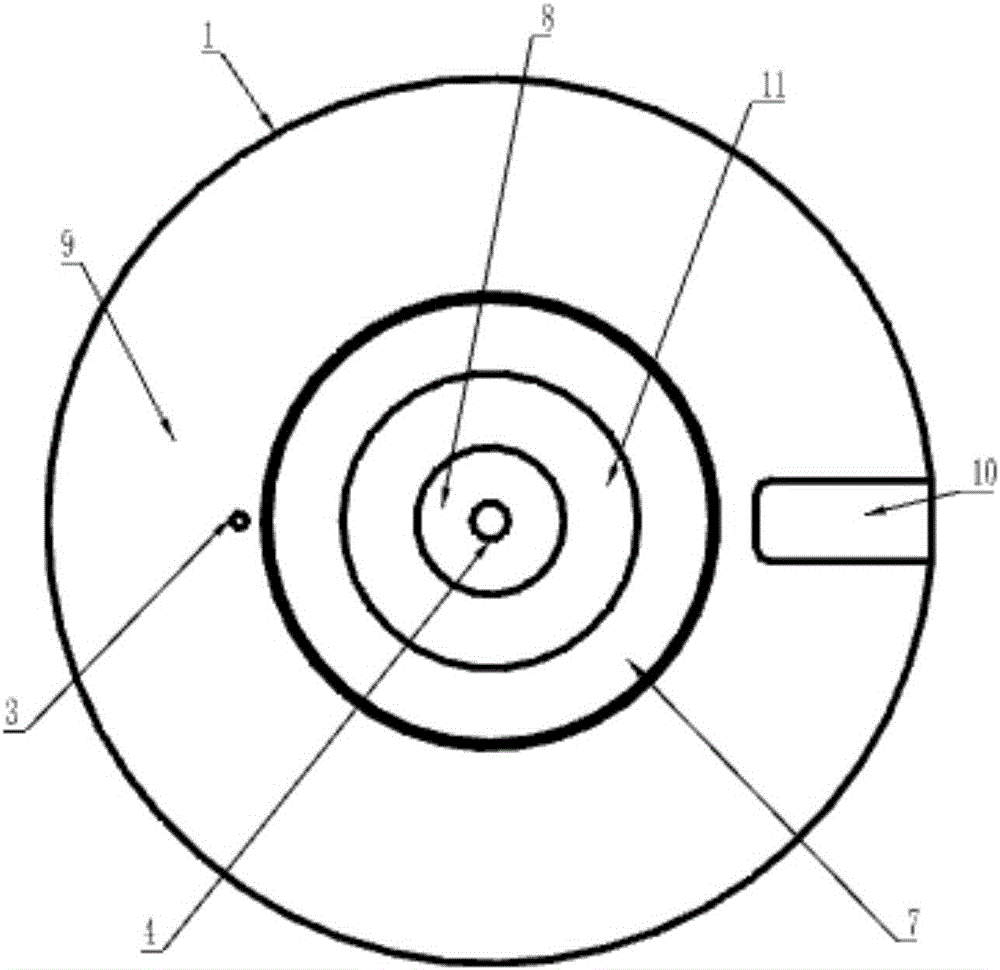

[0022] exist Figure 1-Figure 5 In the shown embodiment, a vacuum fixture for photolithography of a thin film circuit ceramic sheet with holes includes: an alignment shunt chassis 1 and its alignment marking line 6 located on the bisector of the circumferential angle, and the alignment shunt chassis 1 1. The adsorption table 2 in the lower end of the chassis is installed in the groove 5. The counter-distribution chassis 1 is formed with two circular planes consisting of three concentric circular platforms with different diameters. The center of the circular platform is formed with an air guide hole 4 and grooves 11 located on both sides of the air guide hole 4 and the adsorption surface 7 and sealing surface formed by it. 8, wherein the grooves 11 located on both sides of the air guide hole 4 form two air paths that are airtight with the vacuum equipment; the side of the adjacent root of the flange ring surface 9 connected to the concentric circle platform is provided with a mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com