Gas sensor

A gas sensor and sensor element technology, applied in instruments, scientific instruments, and material analysis using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as limiting fast calibration and fast measurement, and achieve small thermal mass, high duty cycle, Effect of Reducing Power Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following description of the figures, identical or identically acting elements are assigned the same reference numerals, so that their descriptions can be interchanged with one another in the different exemplary embodiments.

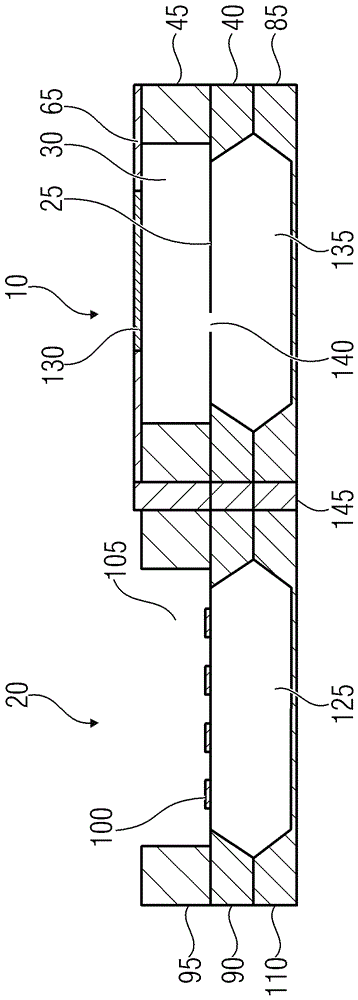

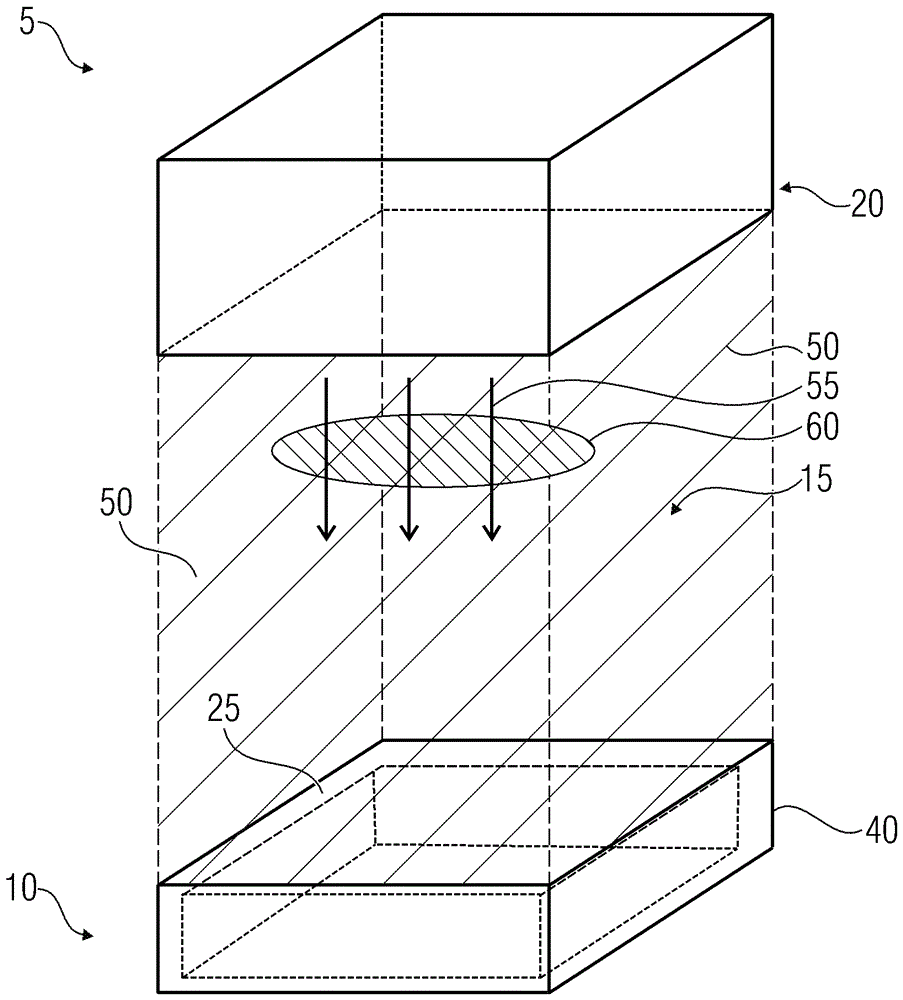

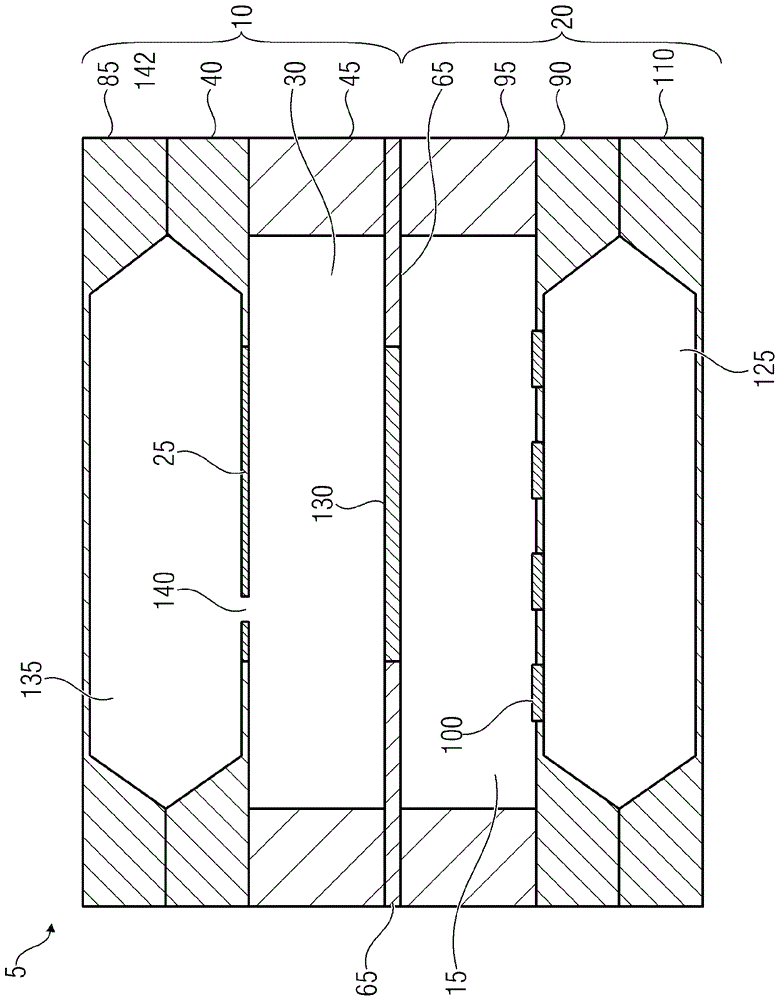

[0039] FIG. 1 a shows a gas sensor 5 with a sensor element 10 , a measuring chamber 15 and an emitter element 20 . The sensor element 10 has a MEMS membrane 25 which is arranged in a first substrate region 40 . The measuring chamber 15 is designed to accommodate a measuring gas 50 . Furthermore, according to one embodiment, the sensor element 10 and the emitter element 20 can have a hermetically closed connection such that a hermetically closed measuring chamber 15 is formed. This can prolong the lifetime of the emitter element 20 or the entire gas sensor since it operates in a protective atmosphere. The same effect can also be achieved by a housing surrounding the gas sensor. The MEMS membrane forms, for example, a micromechanical capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com