Two-stage annular gap throttling device

A technology of annular gaps and throttling devices, which is applied in the direction of bearing assembly, bearings, shafts and bearings, etc., can solve the problems of difficult to arrange oil holes, cumbersome, narrowing the use range of throttles, etc., and achieve the effect of compact structure and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

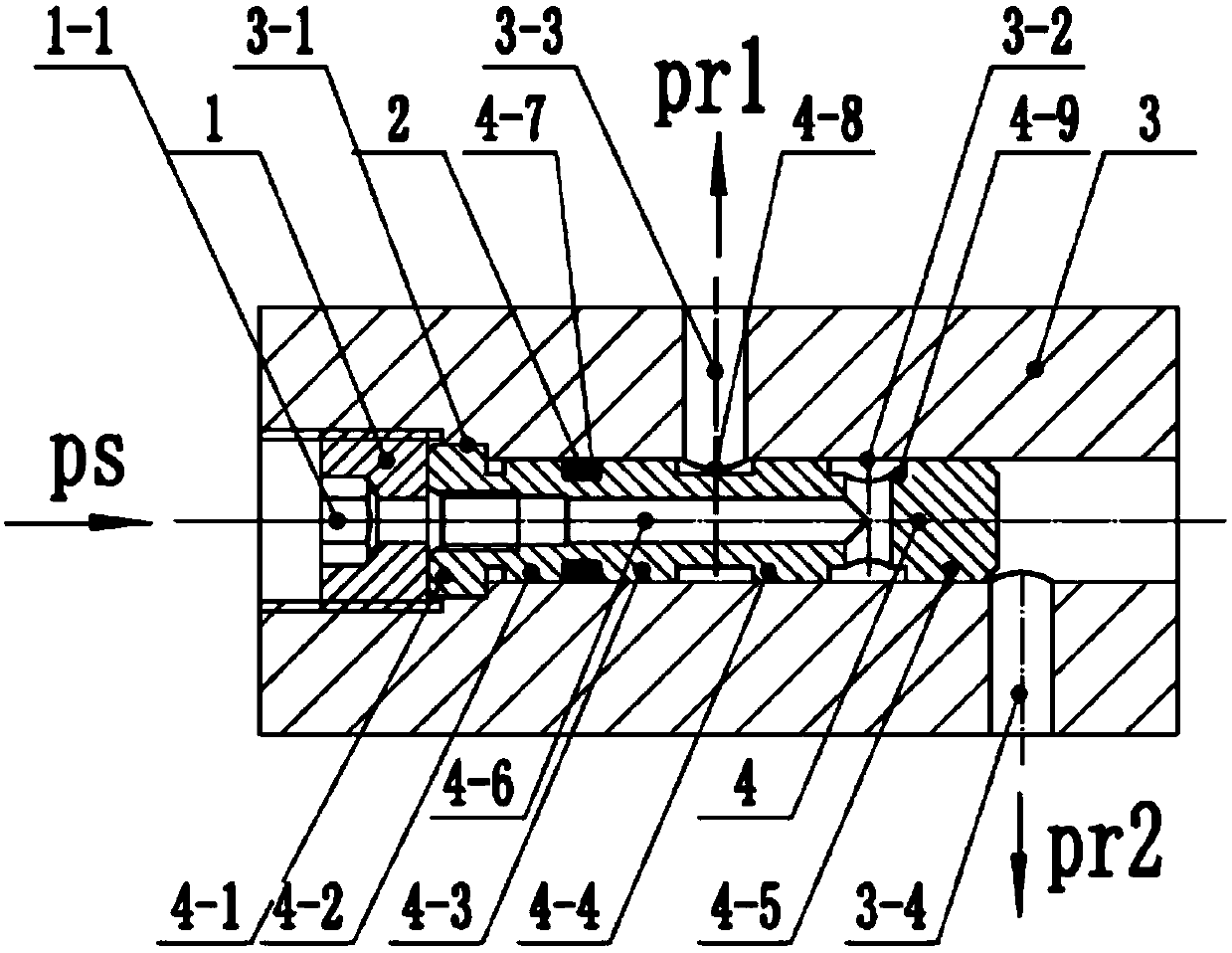

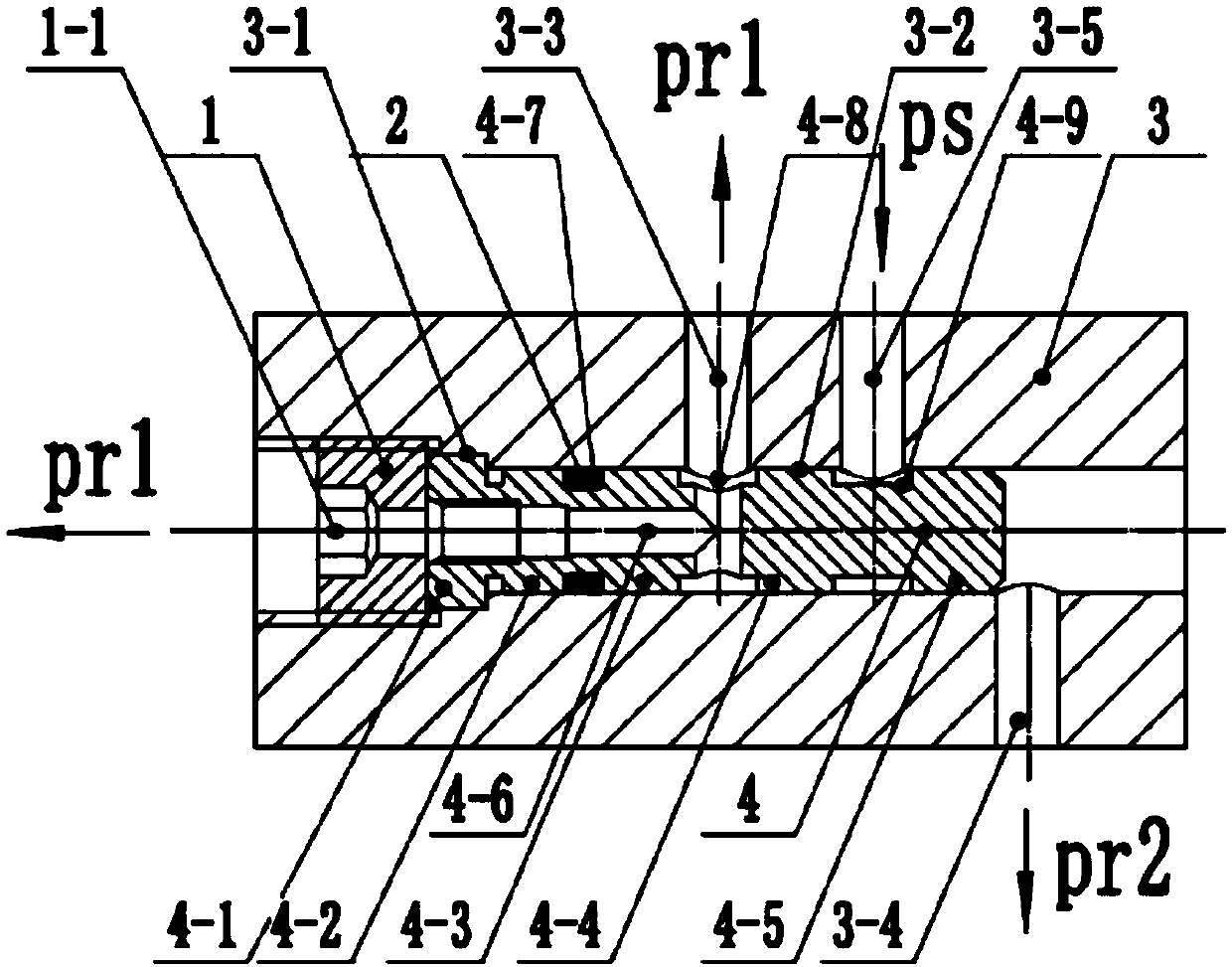

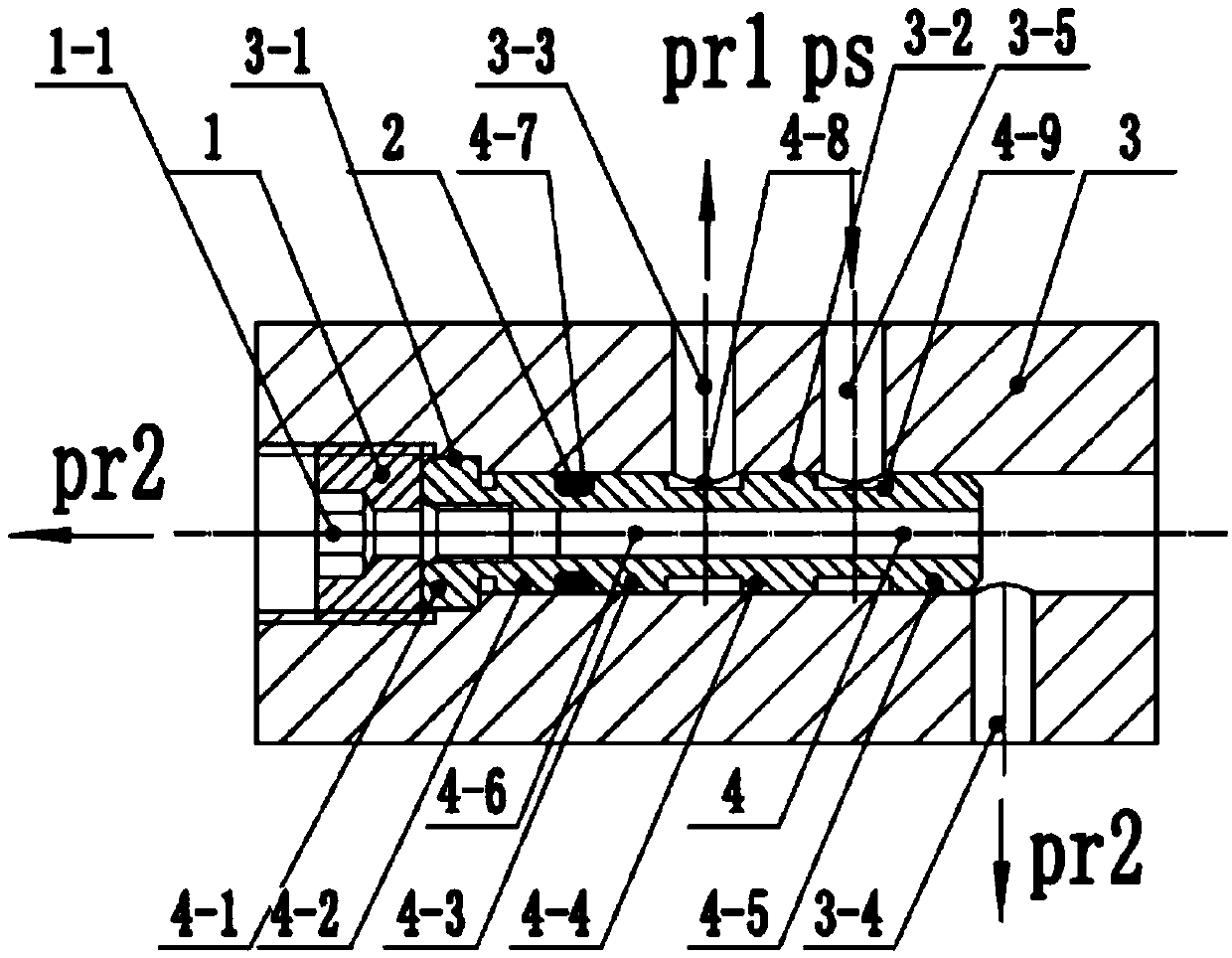

[0025] The first throttling section 4-4 and the second throttling section 4-5 of the throttle body 4 are machined with the same outer diameter and length, and the rear cavity 3-2 of the throttle mounting body 3 is Reaming process of the reamer, the first throttle section 4-4 and the second throttle section 4-5 and the rear cavity 3-2 respectively form a throttle gap, and the throttle gap is calculated according to the throttle liquid resistance of the opposite oil cavity Sure. The first installation section 4-2 and the second installation section 4-3 of the restrictor body 4 are machined with the same outer diameter and have the same outer diameter, and the installation gap between the rear cavity 3-2 and the rear cavity 3-2 is smaller than the throttling gap, about It is 1 / 7 ~ 1 / 15. After the sealing annular groove 4-7 of the restrictor body 4 is installed into the O-ring, it is axially pressed on the bottom of the front cavity 3-1 of the restrictor mounting body 3 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com