Intelligent heat-color light-dimming energy-saving glass and manufacturing method thereof

An intelligent dimming and energy-saving glass technology, applied in the direction of parallel glass structure, optics, nonlinear optics, etc., can solve the problems of long annealing temperature, reduced effective absorption rate of radiation rays by the film layer, and prolonged annealing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

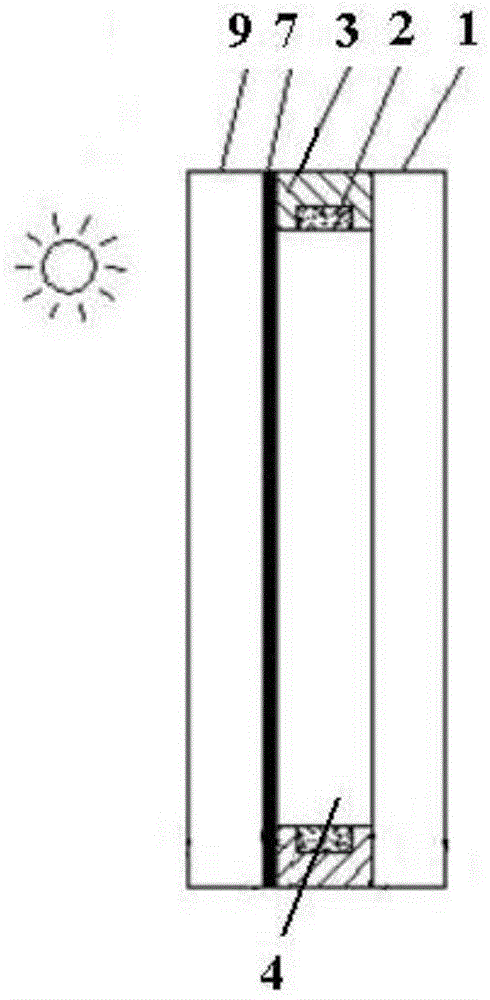

[0073] combine figure 1 As mentioned above, the structure of the energy-saving glass in this embodiment is as follows: the first glass layer (10mm physically tempered glass substrate), the frame (and sealant) filled with molecular sieves, the second glass layer (4mm physically tempered glass substrate), Film (0.76mm transparent PVB), thermochromic smart film layer (located on the side of the third glass layer facing the film), third glass layer (4mm physically tempered glass substrate).

[0074] The preparation method is as follows:

[0075] (1) A glass substrate is provided. Physically toughen two pieces of 4mm ordinary float glass to form a glass substrate with a surface stress of 100MPa (respectively the second glass layer and the third glass layer), and physically toughen a piece of 10mm ordinary float glass to form a glass substrate with a surface stress of 100MPa sheet (first glass layer).

[0076] (2) Deposit the film layer. G / SixNy(30nm) / VOx(120nm) / SixNy(150nm) is ...

Embodiment 2

[0083] Compared with Example 1, the difference is that the second and third glass layers are 4mm semi-tempered glass substrates, the first glass layer is a 5mm physically tempered glass substrate, and the thermochromic intelligent film layer is deposited on the second glass layer On the surface of the substrate, the deposited film structure is G / ITO (150nm) / VOx (150nm) / SixNy (50nm). x=2.15 of VOx, where x is the average number of atoms. Annealing time 55s. In the process of preparing the interlayer, the third glass layer, 0.76mmPVB, and the second coated glass layer are stacked in sequence, and the film surface is located on the top (that is, the last thermochromatic intelligent film layer is located on the side of the sealed hollow cavity). Then adopt vacuum method to carry out high-temperature and high-pressure molding to form a glass composite body.

Embodiment 3

[0085]Compared with Example 1, the difference is that the second and third glass layers are common 4mm float glass, and the thermochromatic intelligent film layer is deposited on the second glass layer substrate surface, and the film layer structure is G / SixNy (80nm ) / NiCrOx(1nm) / VOx(30nm) / NiCrOx(15nm) / SixNy(150nm). In VOx, x=1.75, where x is the average number of atoms. Annealing time 135s. In the process of preparing the interlayer, the third glass layer, 0.76mm PVB, and the second coated glass layer are stacked in sequence. The film surface is adjacent to the PVB film, and then the glass composite is formed by high temperature and high pressure forming by rolling. The thermochromatic intelligent film layer is located in the second The second glass layer faces the side of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface stress | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com