Aluminum alloy anodic oxidation surface treatment process

A technology of anodizing and surface treatment, which is applied in the direction of anodizing, electrolytic coating, electrophoretic plating, etc., to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

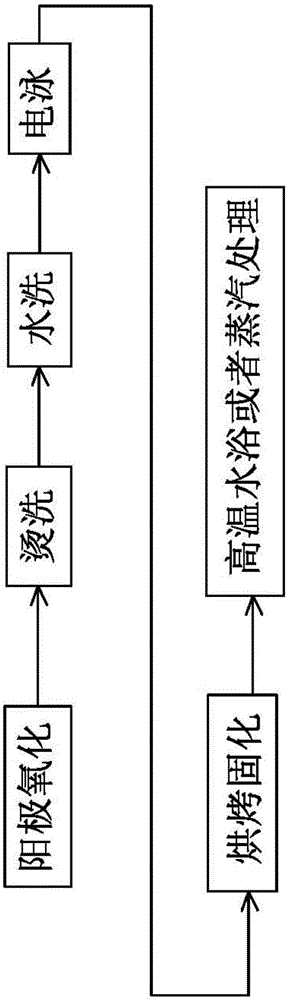

[0021] Test sample specification: 40*100*2mm EN AW 6401 (extrusion profile), the obtained sample number is A, and the sample number is A according to figure 1 The process steps shown are for treatment, anodizing: anodizing the metal to form an oxide film on the metal surface; scalding: immerse the anodized metal in a hot water tank for scalding for 5 minutes, the hot water tank is filled with pure water, and the water temperature is 50 °C; Water washing: immerse the scalded metal in a recovery tank for washing and soaking for 1 minute, the recovery tank contains pure water, the pH value of the pure water is less than 7.5; electrophoresis: immerse the washed metal in the electrophoresis tank for electrophoresis, the pH in the electrophoresis tank The value is controlled at 7.5; baking curing: bake the metal after electrophoresis, the baking curing temperature is 165 ° C, and the curing time is 20 minutes; high temperature water (steam) post-treatment: put the baked and cured coa...

Embodiment 2

[0023] Test sample specification: 40*100*2mm EN AW 6401 (extruded profile), the obtained sample number is B, and the sample number is B according to figure 1 The process steps shown are for treatment, anodizing: anodizing the metal to form an oxide film on the metal surface; scalding: immerse the anodized metal in a hot water tank for 6 minutes and scald it for 6 minutes. The hot water tank is filled with pure water, and the water temperature is 75 °C; Water washing: immerse the scalded metal in a recovery tank for washing and soaking for 2 minutes, the recovery tank contains pure water, the pH value of the pure water is less than 7.5; electrophoresis: immerse the washed metal in the electrophoresis tank for electrophoresis, the pH in the electrophoresis tank The value is controlled at 8; baking curing: bake the metal after electrophoresis, the baking curing temperature is 180 ° C, and the curing time is 30 minutes; high temperature water (steam) post-treatment: put the baked a...

Embodiment 3

[0025] Test sample specification: 40*100*2mm EN AW 6401 (extrusion profile), the obtained sample number is C, and the sample number is C according to figure 1 The process steps shown are for treatment, anodizing: anodizing the metal to form an oxide film on the metal surface; scalding: immerse the anodized metal in a hot water tank for scalding for 5.5 minutes, the hot water tank is filled with pure water, and the water temperature is 65 °C; Water washing: immerse the scalded metal in a recovery tank for washing and soaking for 1.5 minutes, the recovery tank contains pure water, the pH value of the pure water is less than 7.5; electrophoresis: immerse the washed metal in the electrophoresis tank for electrophoresis, the pH in the electrophoresis tank The value is controlled at 7.7; baking and curing: bake the metal after electrophoresis, the baking and curing temperature is 173 ° C, and the curing time is 25 minutes; high-temperature water (steam) post-treatment: put the baked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com