Technological process for achieving size miniaturization of inclusion in Si deoxidized steel

A technology of process flow and inclusions, which is applied in the field of process flow to realize the miniaturization of inclusions in Si deoxidized steel. It can solve the problems that the deformation performance is not conducive to the miniaturization of inclusions, and the synergy has not been studied, so as to achieve miniaturization. , Improve the effect of drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

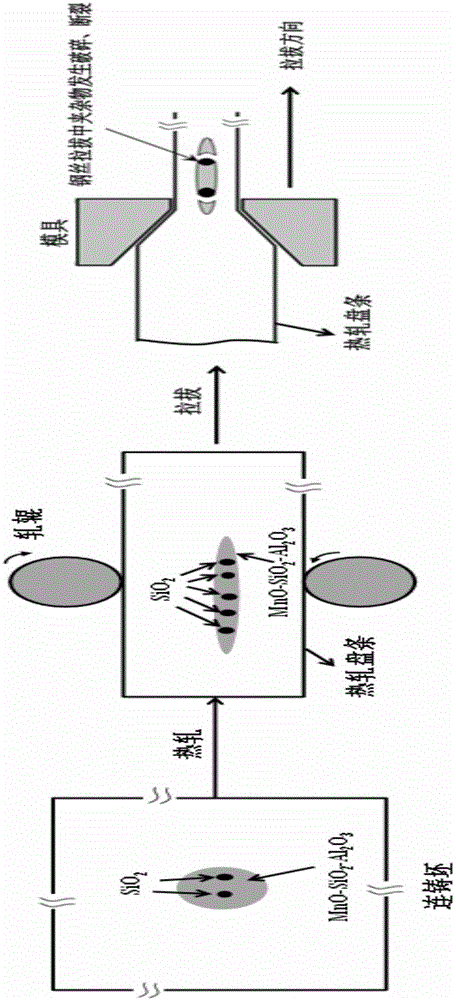

[0018] (1) Add low-aluminum ferrosilicon and low-aluminum ferromanganese to the ladle for about 1 / 5~2 / 5 of the time when the steel is tapped from the converter / electric furnace;

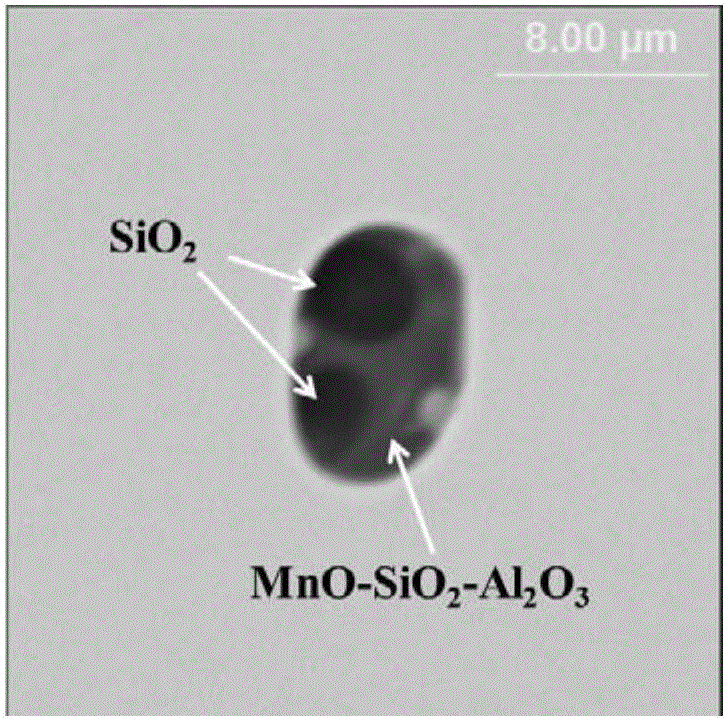

[0019] (2) During ladle refining, the slag must be controlled at the same time with an alkalinity of about 0.5~1.0, Al 2 o 3 The content is controlled at 0~10wt%, (Fe t O+MnO)<2wt%;

[0020] (3) The oxygen concentration in the ladle during refining and in the tundish during pouring is controlled below 0.5%: argon gas must be injected into the ladle during refining to ensure a slightly positive pressure atmosphere in the furnace, and Ar gas must be injected into the tundish before pouring. ~20min and continuous flow of Ar gas for sealing operation during the whole pouring process;

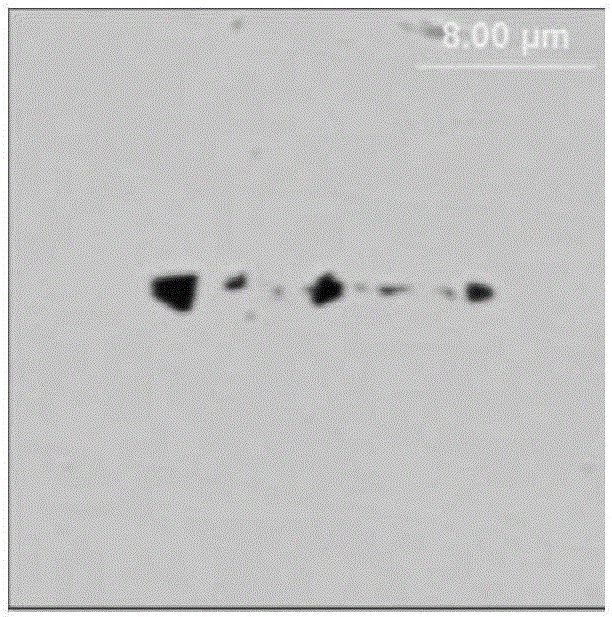

[0021] (4) Large-section continuous casting slabs are used for continuous casting, and the continuous casting slabs are heated to 1100~1270°C before hot rolling and kept for a long time (3~10 hours) before hot rolling; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com