Catalytic pyrolysis method of biomass and/or coal

A biomass and catalyst technology, applied in the field of catalytic pyrolysis of biomass and/or coal, can solve problems such as control of unfavorable conditions, and achieve the effects of optimizing conversion conditions, simple process, and simplifying component composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Catalyst preparation: 28ml K 3 PO 4 Add the saturated aqueous solution of 20g of γ-Al with a particle size of 1-2mm dropwise 2 o 3 On the granules, the dropwise addition is completed and dried naturally for 24 hours, then dried at 125°C for 12 hours, then transferred to a muffle furnace for 700°C roasting for 8 hours, and cooled in a desiccator to obtain γ-Al 2 o 3 potassium salt catalyst.

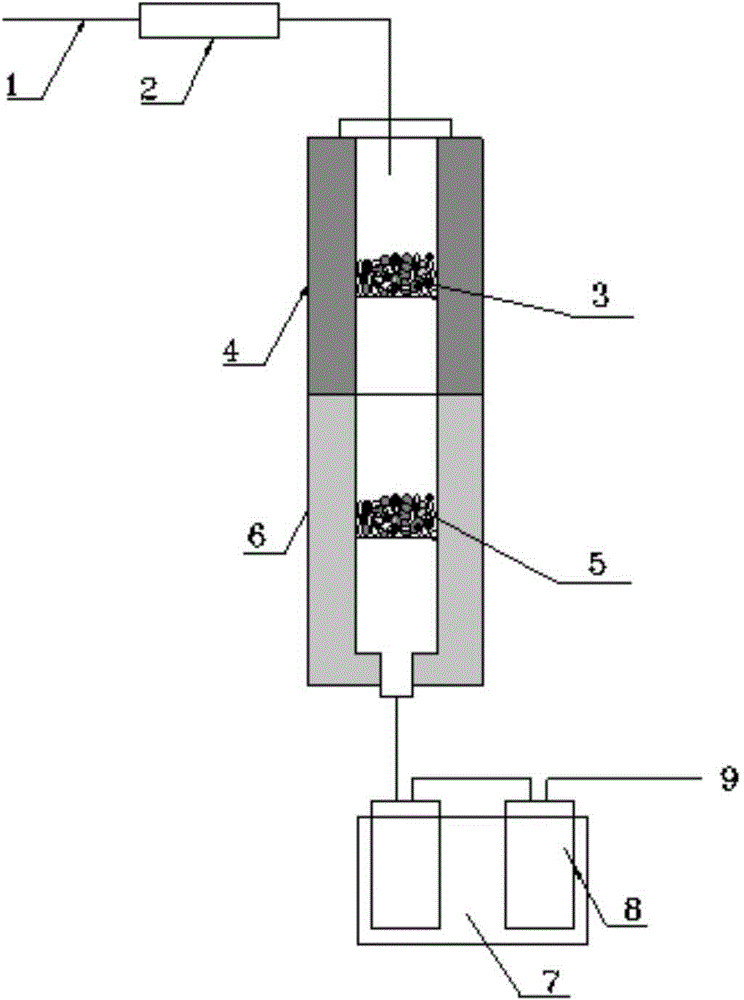

[0037] Catalytic pyrolysis of biomass and / or coal: put 15g of pine wood powder with a particle size of less than 2mm into the first constant temperature zone 4 of the fixed bed reactor, and place 15g of catalyst in the second constant temperature zone 6 of the fixed bed reactor, and pyrolyze the obtained The high-temperature gas-phase product flows out from the outlet of the tubular reactor and enters the low-temperature condensation unit 7, where it is cooled and collected in a liquid phase. The heating rate is 20°C / min, the temperature in the first constant temperature zone 4...

Embodiment 2

[0039] Catalyst preparation: 30ml KH 2 PO 4 Add the saturated aqueous solution of 20g of γ-Al with a particle size of 1-2mm dropwise 2 o 3 On the granules, the dropwise addition is completed and dried naturally for 12 hours, then dried at 140°C for 8 hours, then transferred to a muffle furnace for 800°C roasting for 9 hours, and cooled in a desiccator to obtain γ-Al 2 o 3 potassium salt catalyst.

[0040] Catalytic pyrolysis of biomass and / or coal: put 15g of rice husks with a particle size of less than 1mm into the first constant temperature zone 4 of the fixed bed reactor, and place 15g of catalyst in the second constant temperature zone 6 of the fixed bed reactor, and pyrolyze the obtained The high-temperature gas-phase product flows out from the outlet of the tubular reactor and enters the low-temperature condensation unit 7, where it is cooled and collected in a liquid phase. The heating rate is 9°C / min, the temperature in the first constant temperature zone 4 is con...

Embodiment 3

[0042] Catalyst preparation: 30ml Na 2 HPO 4 Add the saturated aqueous solution of 20g of γ-Al with a particle size of 1-2mm dropwise 2 o 3 On the granules, the dropwise addition is completed and dried naturally for 24 hours, then dried at 150°C for 10 hours, then transferred to a muffle furnace for 600°C and roasted for 10 hours, and cooled in a desiccator to obtain γ-Al 2 o 3 sodium salt catalyst.

[0043] Catalytic pyrolysis of biomass and / or coal: Put 20g of Huolinhe coal with particle size less than 1.5mm into zone 4 of the first constant temperature zone of the fixed bed reactor, and place 5g of catalyst in the second constant temperature zone 6 of the fixed bed reactor , The high-temperature gas-phase product obtained by pyrolysis flows out from the outlet of the tubular reactor and enters the low-temperature condensation unit 7, and is cooled to become a liquid phase and collected. The heating rate is 30°C / min, the temperature in the first constant temperature zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com