Castor oil base containing antibacterial UV coating and preparation method and application thereof

A castor oil-based coating technology, applied in the coating field, can solve problems such as single performance, and achieve the effects of fast curing speed, little environmental pollution, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of traditional antibacterial photocuring coating:

[0054] ①Sequentially add 51g of water-based polyurethane acrylate, 10g of trimethylolpropane triacrylate diluent, 8g of tripropylene glycol diacrylate diluent and 14g of ethyl acetate solvent, and disperse at 1000r / min for 30min;

[0055] ② Then add 0.5g of acrylic resin leveling agent and 2.5g of photoinitiator, and disperse at 800r / min for 30min;

[0056] ③ Slowly add 2g of nano-silver antibacterial additive at 400r / min, and continue to disperse for 30min;

[0057] ④ Finally, add 12g of butyl acetate solvent to Iwata 2# cup and adjust the viscosity to 20s at 25°C to obtain the traditional antibacterial light-curing coating.

Embodiment 2

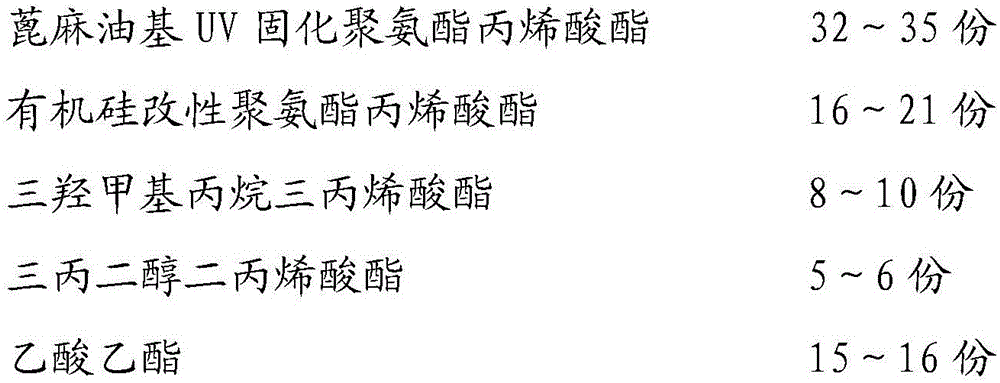

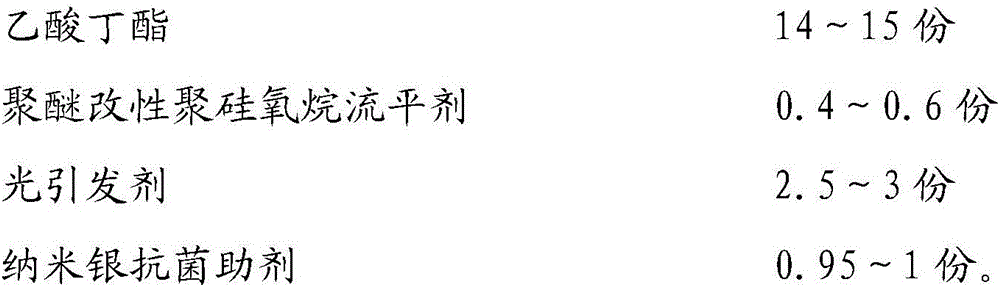

[0059] A kind of antibacterial UV paint containing castor oil base, it is prepared by following component distribution ratio and preparation method:

[0060] S1, preparation of castor oil-based UV curing polyurethane acrylate:

[0061] S11. Mix and stir 5.8 mol of polyethylene glycol, 1.5 mol of polyester diol and 1 mol of castor oil evenly and raise the temperature to 115°C, dehydrate under reduced pressure for 2.5 hours and then cool down to 75°C, then add 1 mol of isoflurane respectively Ketone diisocyanate and the bismuth laurate catalyst of 0.002mol, the drop rate is controlled to be dropped within 1.5h, and the reaction is 3h to obtain the mixed solution M;

[0062] S12, 0.3mol of N,N-dimethylformamide is dissolved in 2mol of bisphenol A solvent and 0.3mol of 2,2-dimethylolpropionic acid solvent and then mixed with 3mol of butanone to obtain a mixed Solution N;

[0063] S13. Add the mixed solution N prepared in the step S12 into the mixed solution M prepared in the ste...

Embodiment 3

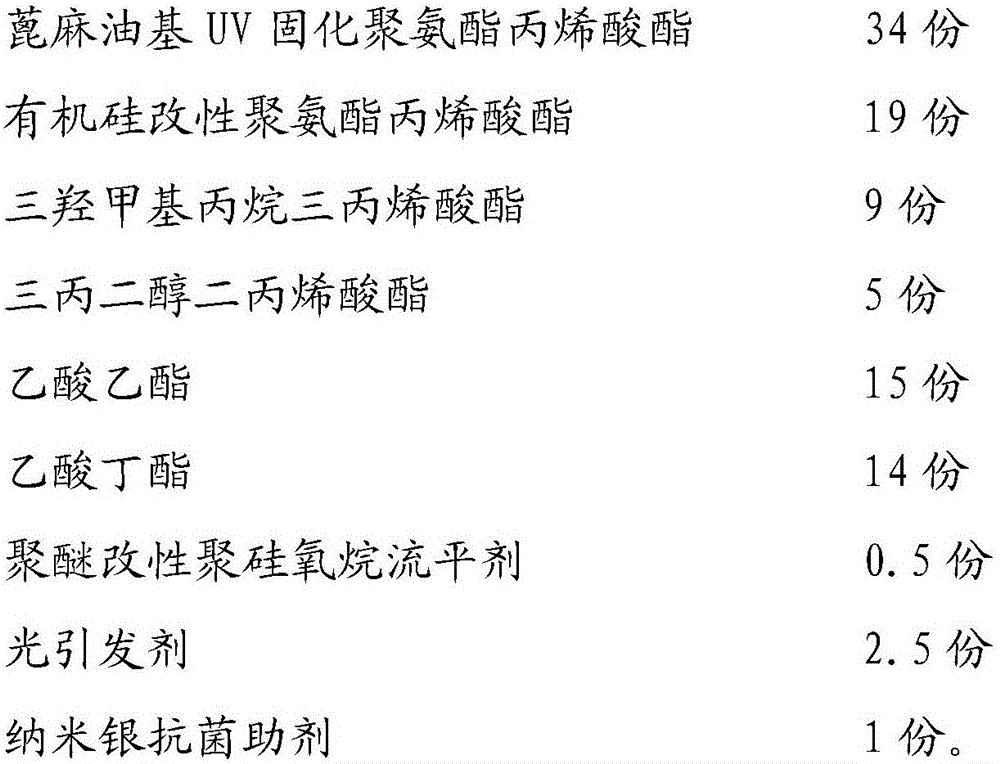

[0076] A kind of antibacterial UV paint containing castor oil base, it is prepared by following component distribution ratio and preparation method:

[0077] S1, preparation of castor oil-based UV curing polyurethane acrylate:

[0078] S11. Mix and stir 5.5 mol of polyethylene glycol, 2 mol of polyester diol and 1 mol of castor oil, and heat up to 110°C, dehydrate under reduced pressure for 3 hours, then cool down to 72°C, and then add 1mol of isophorone two The bismuth laurate catalyst of isocyanate and 0.002mol, the drop rate is controlled to drop in 1.5h, react 2.5h, obtain mixed solution M;

[0079] S12. Dissolve 0.3mol of N,N-dimethylformamide in 3mol of bisphenol A solvent and 0.3mol of 2,2-dimethylolpropionic acid solvent and mix with 2mol of butanone to obtain a mixed Solution N;

[0080] S13. Add the mixed solution N prepared in the step S12 into the mixed solution M prepared in the step S11, and continue the reaction. When the content of the isocyanate group reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com