Lifting equipment for electronic element bearing tray

A technology of electronic components and lifting equipment, which is applied in the field of lifting equipment that can lift and transfer electronic component carrying trays, can solve the problems of difficult assembly or maintenance, complex mechanisms and pipelines, and high construction costs, so as to reduce waiting time and reduce costs , the effect of streamlining the overall organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Before the elevating device of the electronic component carrying tray of the present invention is described in detail in this embodiment, it should be noted that in the following description, similar components will be denoted by the same component symbols.

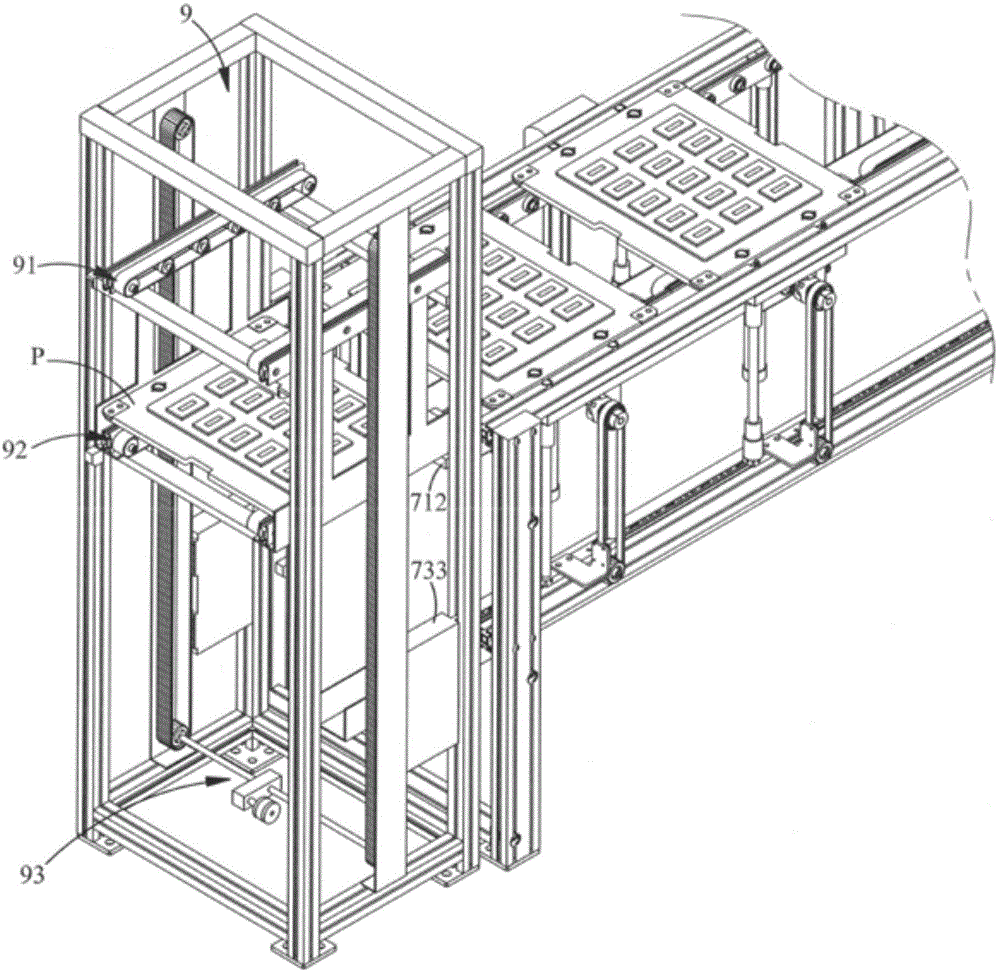

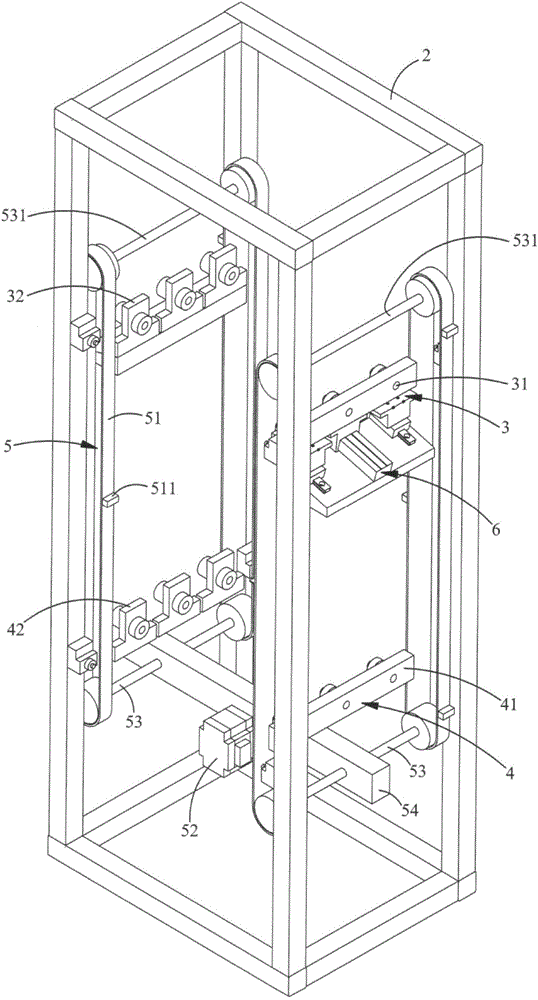

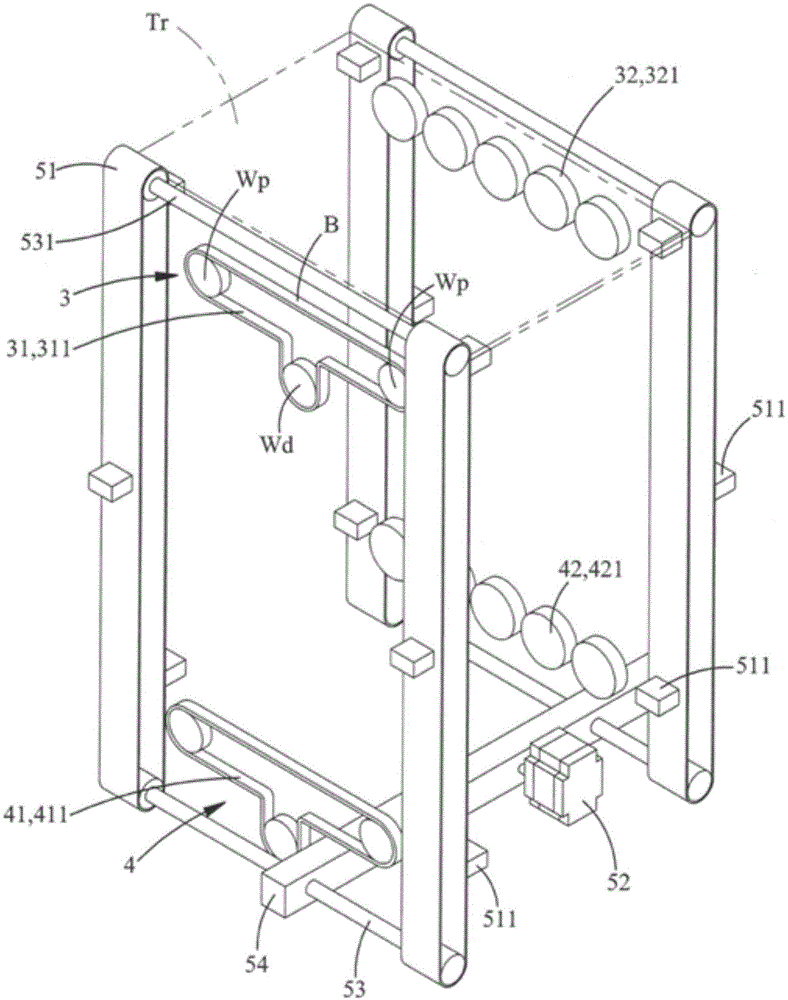

[0079] Please also see Figure 2A and Figure 2B , Figure 2A is a perspective view of the first embodiment of the present invention, Figure 2B It is self Figure 2A The schematic perspective view on the right side is used to show the upper conveying module 3, the lower conveying module 4 and the belt lifting module 5 of the first embodiment of the present invention from another angle, wherein in order to show the details of each module more clearly And save fixed frame 2 and retraction mechanism 6. The elevating device of the electronic component carrying tray of this embodiment is used to drive a conventional electronic component carrying tray Tr (shown by a phantom line) to rise or fall, and the electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com