High pressure water cooling method and device applied to low pressure casting technology

A low-pressure casting and water-cooling device technology, which is applied in the field of high-pressure water cooling and devices used in low-pressure casting processes, can solve the problems of increasing production costs of manufacturers, reducing the service life of casting molds, and poor cooling effects, etc., so as to reduce production costs , Improve mechanical performance, facilitate assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and a preferred embodiment of the present invention.

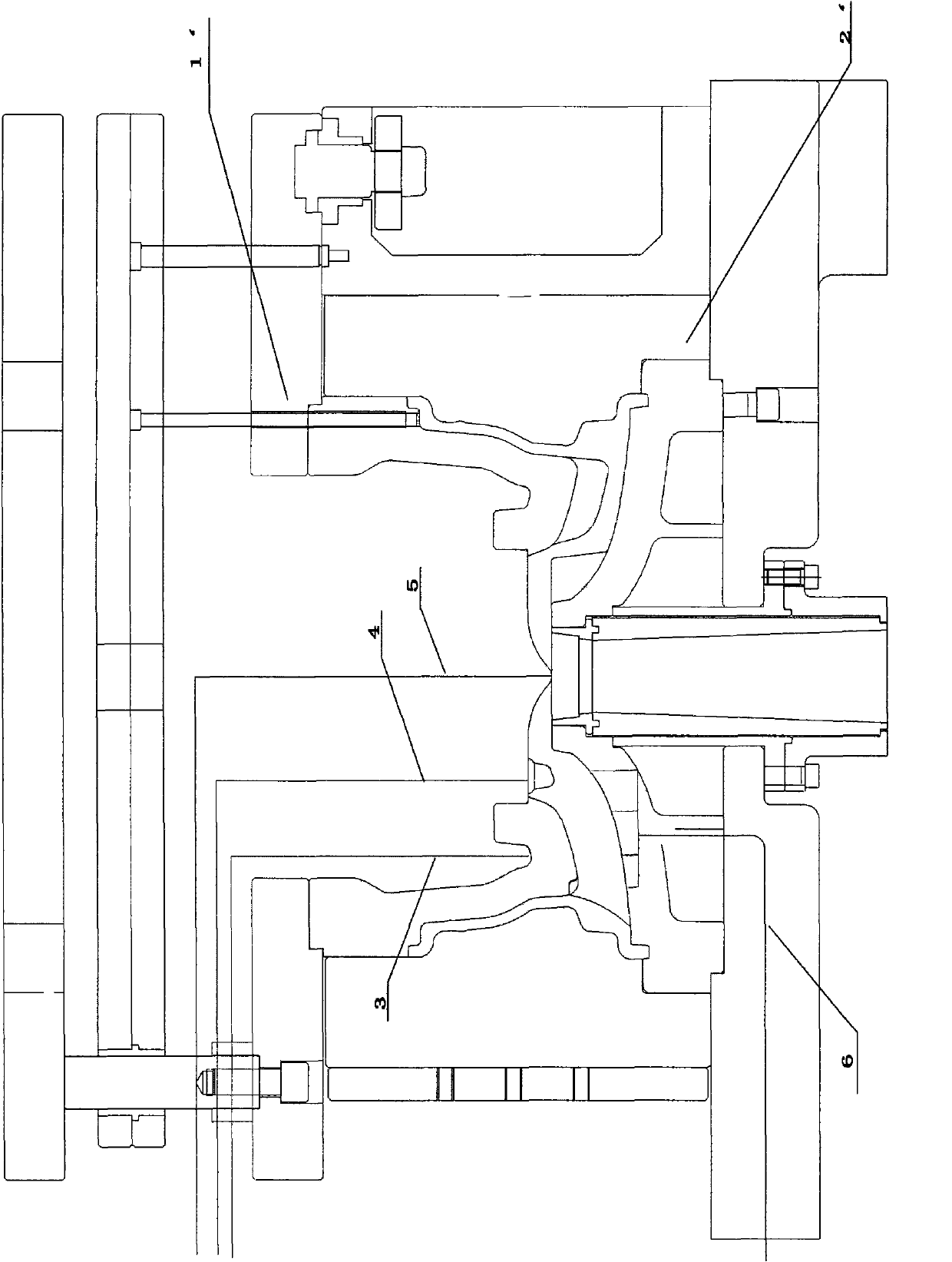

[0028] This embodiment relates to a low-pressure casting process for aluminum alloy automobile wheels. In this process, the casting (namely, the aluminum alloy automobile wheel) is cooled by a high-pressure water cooling method. The high-pressure water cooling method is realized by a high-pressure water cooling device. Such as Figure 3-4 The high-pressure water cooling device includes upper and lower mold water cooling plates 7 and 8 fixedly arranged on the inner sides of the upper mold 1 and the lower mold 2 of the casting mould, respectively, at the corresponding hub PCD positions. The upper mold water cooling plate 7 and the lower mold water cooling plate 8 are both The disc-shaped component has a hollow inner cavity, and two cooling water input ports and two cooling water output ports ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com