Chain adjuster assembly and motorcycle thereof

A regulator and chain technology, used in vehicle parts, vehicle gearboxes, chain/belt drives, etc., can solve the problems of unreliable limit, affect limit accuracy, poor versatility, etc., and reduce mold costs and materials. High cost and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

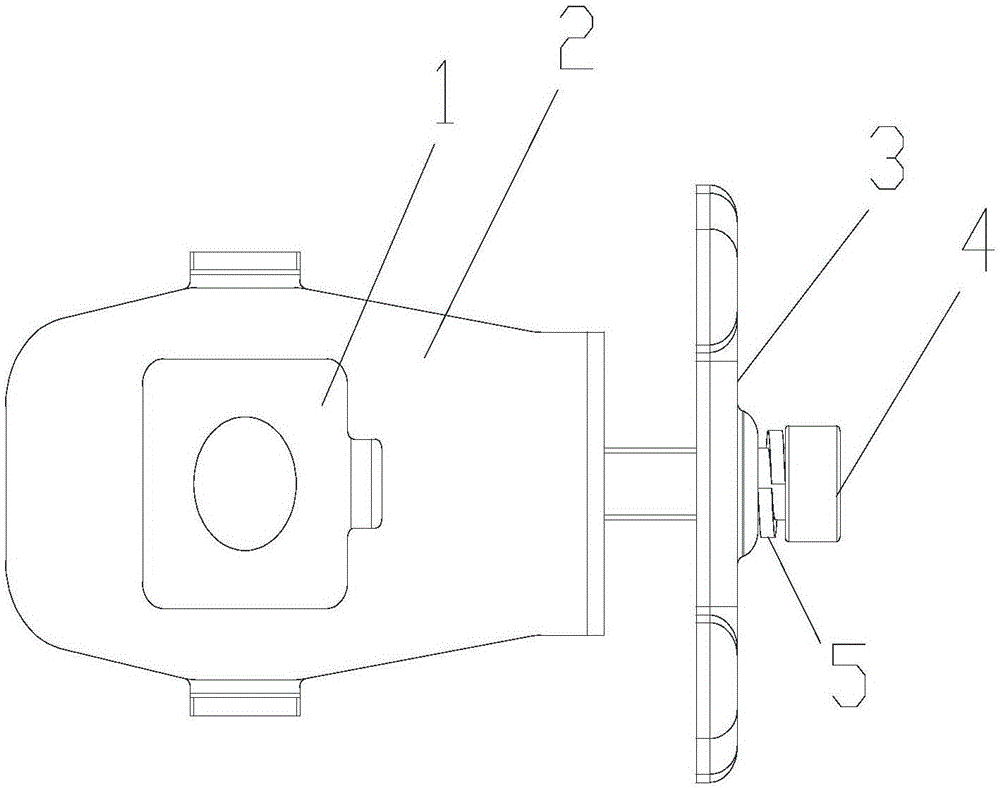

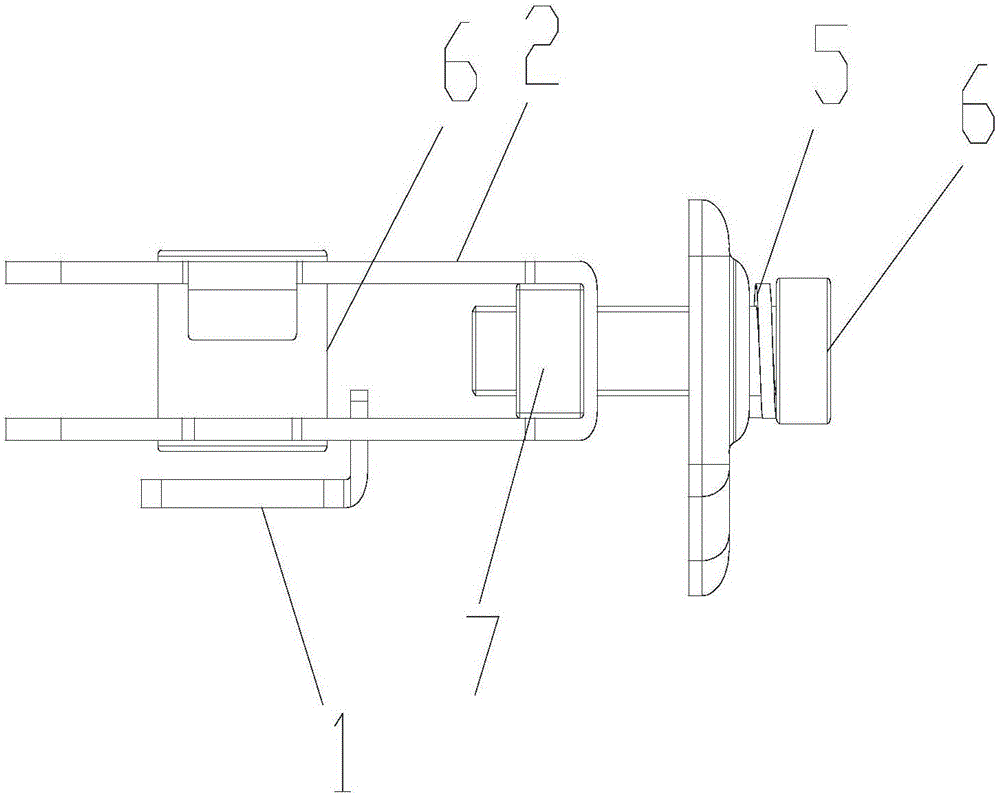

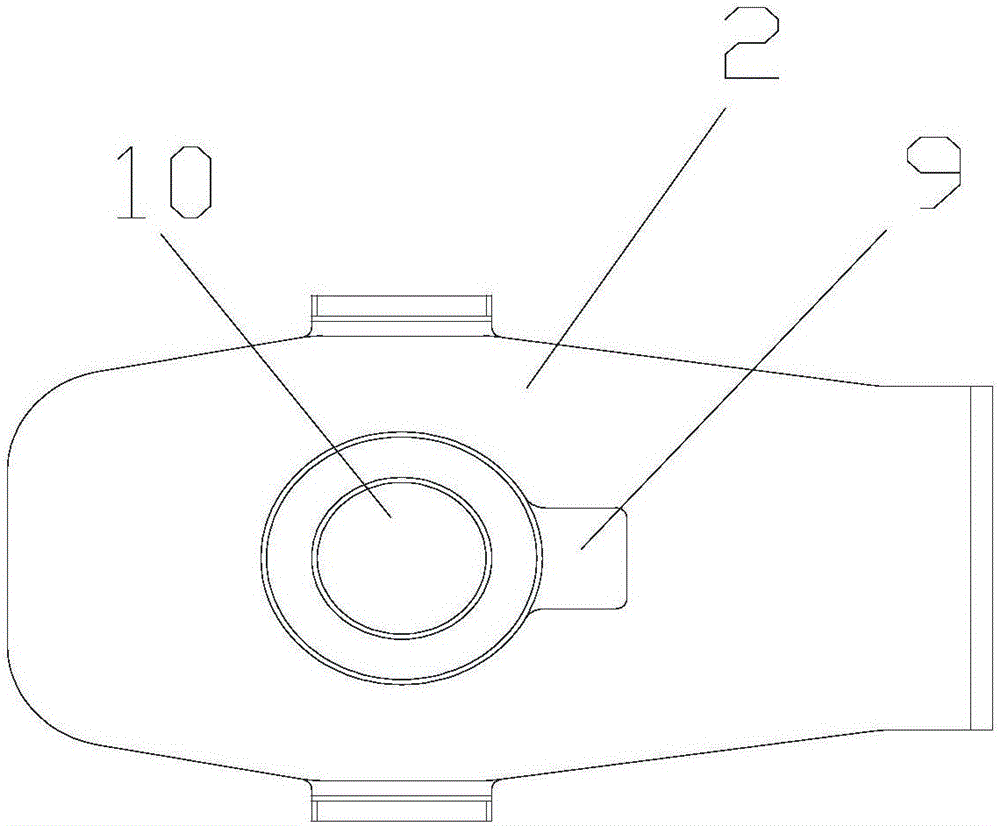

[0025] figure 1 It is a schematic diagram of the structure of the present invention; as shown in the figure: the chain adjuster assembly of this embodiment includes a flat fork and a chain adjustment assembly installed in the side tube 11 of the flat fork. Adjuster main body 2 with hole 10 and sliding fit with the side tube 11 of the flat fork, a position adjustment mechanism for driving the adjuster main body 2 to move longitudinally along the side tube 11, and the adjuster hanging plate 1 for indicating the position of the axle, the adjuster The hanging plate 1 is provided with a limit lug 8, and the lateral sides of the limit lug 8 cooperate with the regulator main body 2 to limit its rotation around the axis of the axle through hole 10. The bending surface of the existing hanging plate 1 is along a flat surface. The vertical setting of the fork and the contact of the flat fork are used to limit the position. The angle error of the bending will affect the accuracy of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com