Manufacture method for earphone wires

A processing method and wire material technology, applied in cable/conductor manufacturing, electrical components, household components, etc., can solve problems such as easy position deviation, earphone scrapping, and earphone cable length not meeting the size requirements, so as to facilitate control and improve production Efficiency and pass rate, the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

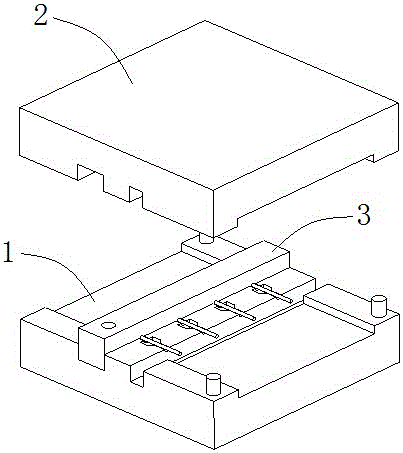

[0020] The present invention will be described in further detail below in conjunction with an injection mold for the tailpiece of the earphone used in the method of the present invention and the accompanying drawings.

[0021] During specific implementation: if figure 1 As shown, an injection mold for an earphone tailpiece includes a lower mold 1 and an upper mold 2 corresponding to the lower mold 1, and the side where the lower mold 1 and the upper mold 2 are bonded respectively have lower molds arranged symmetrically up and down. The casing groove and the upper casing groove, the lower casing groove and the corresponding upper casing groove are fastened together to form a casing hole consistent with the shape of the earphone casing; the casing hole also has a tail to be injected The tail gear injection cavity with the same shape as the tail gear, the tail gear injection cavity includes a lower cavity located on the lower sleeve groove of the lower mold 1, and an upper cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com