Wood modifier, and preparation method and application thereof

A improver, wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of human hazards, toxicity accumulation, high toxicity, etc., and achieve the effect of improving the heat-resistant dimensional stability and humidity-resistant dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The wood improver is made up of the following materials in parts by weight:

[0033] 23-26 parts of sodium carboxymethylcellulose at pH 4.5; 3-4 parts of gum arabic; 4-5 parts of octyl 2-cyanoacrylate; 35-37 parts of ethanol; 1-2 parts of ammonium polyphosphate-boric acid Zinc composite flame retardant, in which the weight of ammonium polyphosphate is twice that of zinc borate, the degree of polymerization of ammonium polyphosphate is 23-25, the phosphorus content is 30%, and the nitrogen content is 16%; 0.2-0.3 parts of citric acid 18-19 parts of water; 0.06-0.08 parts of benzoic acid; 13-15 parts of polylactide-glycolide with a molecular weight of 6000-8000; 0.03-0.04 parts of benzalkonium chloride.

[0034] The wood improver is prepared according to the following production procedures, comprising the following steps:

[0035] 1) Add ethanol and water to the reaction kettle, then add sodium carboxymethylcellulose, stir at a speed of 300 rpm for 30 minutes or continue...

Embodiment 2

[0049] The wood improver is made up of the following materials in parts by weight:

[0050] 26 parts of sodium carboxymethyl cellulose with a pH of 4.5; 3 parts of gum arabic; 4 parts of octyl cyanoacrylate; 37 parts of ethanol; 1 part of ammonium polyphosphate-zinc borate composite flame retardant, wherein ammonium polyphosphate The weight is twice that of zinc borate, the degree of polymerization of ammonium polyphosphate is 23-25, the phosphorus content is 30%, and the nitrogen content is 16%; 0.2 parts of citric acid; 19 parts of water; 0.07 parts of benzoic acid; 13 parts Polylactide-glycolide with a molecular weight of 6000-8000; 0.03 parts of benzalkonium chloride.

[0051] The preparation method of the wood improver and the method of using the wood improver to improve wood are the same as in Example 1.

Embodiment 3

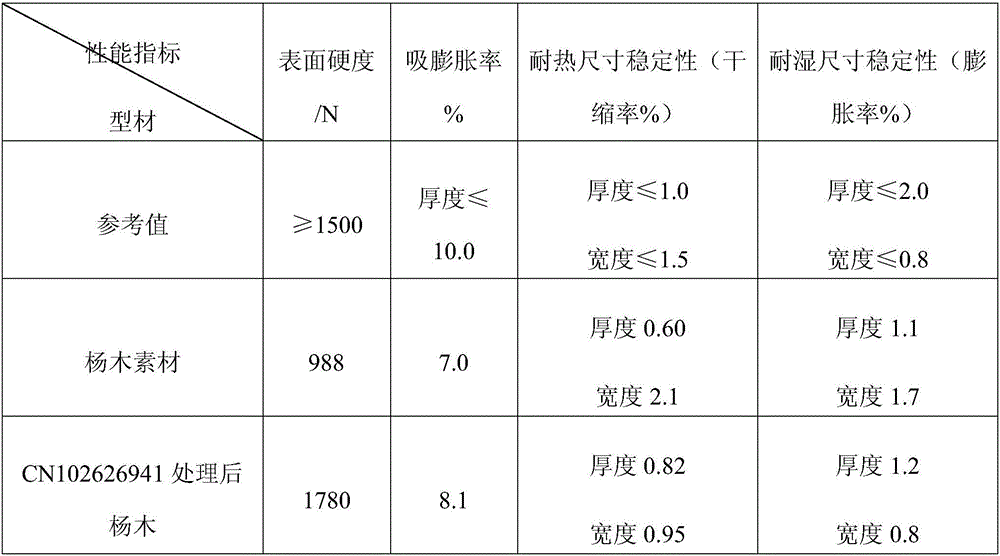

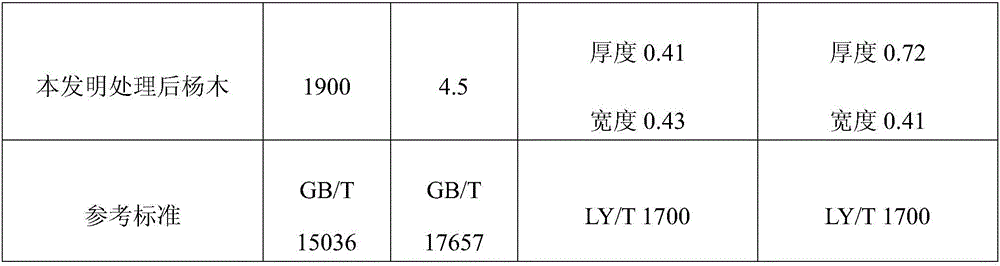

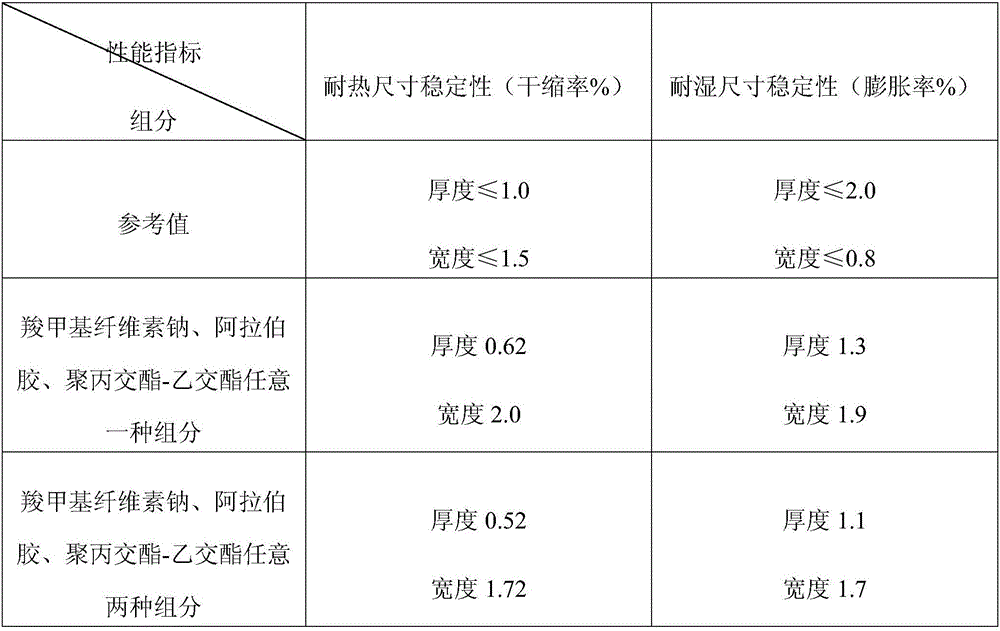

[0053] With reference to the evaluation method of the embodiment in CN102626941, the modified wood of the present invention is evaluated for performance, and the results are as follows in Table 1:

[0054] Table 1 Comparison results of performance evaluation of wood improver of the present invention

[0055]

[0056]

[0057] The above results show that the profile obtained through the technical solution of the present invention has excellent physical properties, overcomes the shortcoming of the fast-growing material itself being soft, and has good heat-resistant / humid dimensional stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com