Grinding wheel clamping mechanism and grinding wheel finishing device using clamping mechanism

A clamping mechanism and grinding wheel technology, applied in the parts of grinding machine tools, abrasive surface adjustment devices, grinding racks, etc. The sharpness of the mouth, the effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

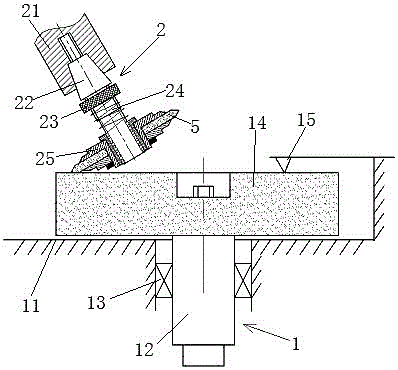

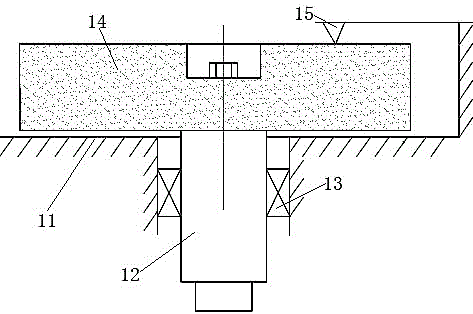

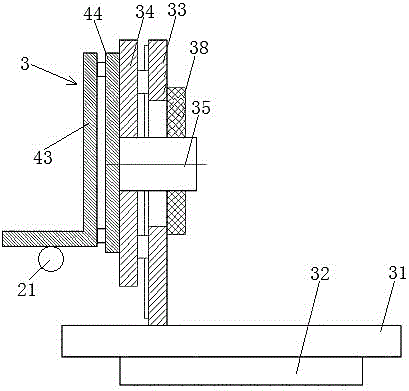

[0031] The specific embodiment of grinding wheel dressing device of the present invention, as Figure 1 to Figure 5 As shown, it includes a grinding host system 1 and a workpiece clamping and feeding system. The workpiece clamping and feeding system includes a grinding wheel clamping mechanism 2 for clamping the grinding wheel to be trimmed, and a three-dimensional slide for driving the grinding wheel to move three-dimensionally in the XYZ direction. Table 3 and the fast-moving mechanism 4 for driving the grinding wheel to fast-forward and fast-rewind.

[0032] The grinding machine system 1 includes a grinding machine body 11 , a grinding machine main shaft 12 , a bearing 13 , a grinding disc 14 (ie, a working wheel), and an online disc repairing mechanism 15 . The main body 11 of the grinding machine is made of cast iron, which is stable and shock-abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com