Manufacturing technology for membrane wall of steel tube of ultra-supercritical large boiler

A large-scale boiler, ultra-supercritical technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A manufacturing process of an ultra-supercritical large-scale boiler steel tube membrane wall, comprising the following steps:

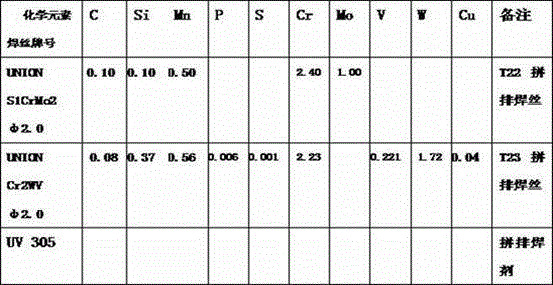

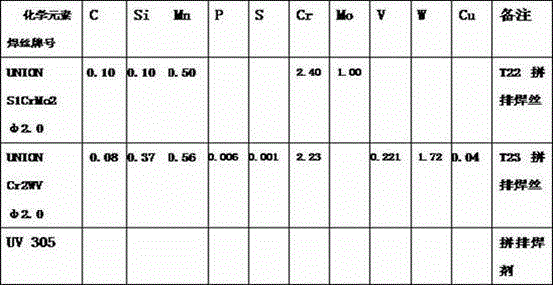

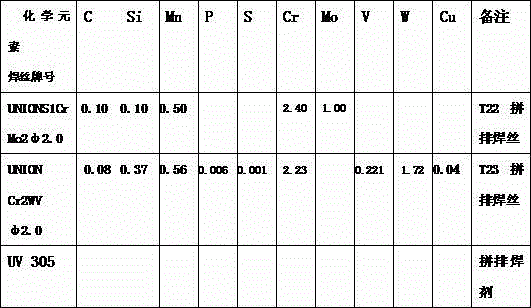

[0013] 1 、 Selection of welded materials: According to the chemical composition and mechanical properties of SA213-T22 and SA213-T23 pipes, the chemical composition of welding materials for SA213-T22 and SA213-T23 pipes and SA387Gr22 flat steel is shown in Table 1:

[0014] Chemical composition of welding materials (%) Table 1

[0015]

[0016] 2. Selection of welded welding specifications: SA213-T22 and SA213-T23 pipes are low-alloy heat-resistant steels. The materials have certain hardenability and the welding stress of the welded fillet joints is relatively large. In order to avoid welding cold cracks, welding The preheating temperature is 150°C; in order to ensure the quality of the rows of bends, the tempering treatment is adopted at 720±10°C after welding; the welding specification is based on the conventional φ2.0 welding wire;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com