A food waste source classification and pretreatment system

A technology for kitchen waste and pretreatment, which is applied in the field of food waste source classification and pretreatment systems, can solve the problems of troublesome kitchen waste collection, low resource utilization rate, difficult transportation, etc. and social benefits, compact and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

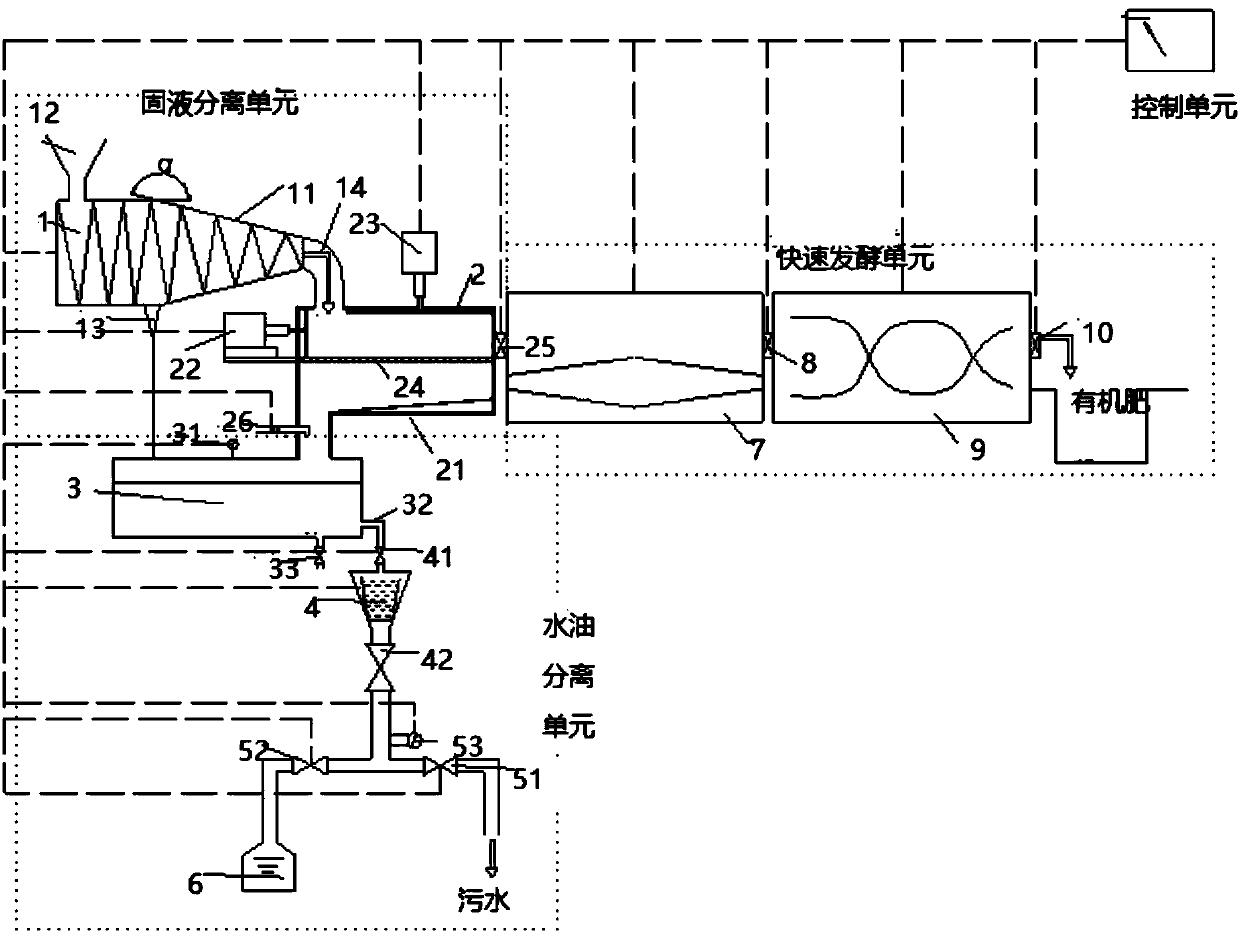

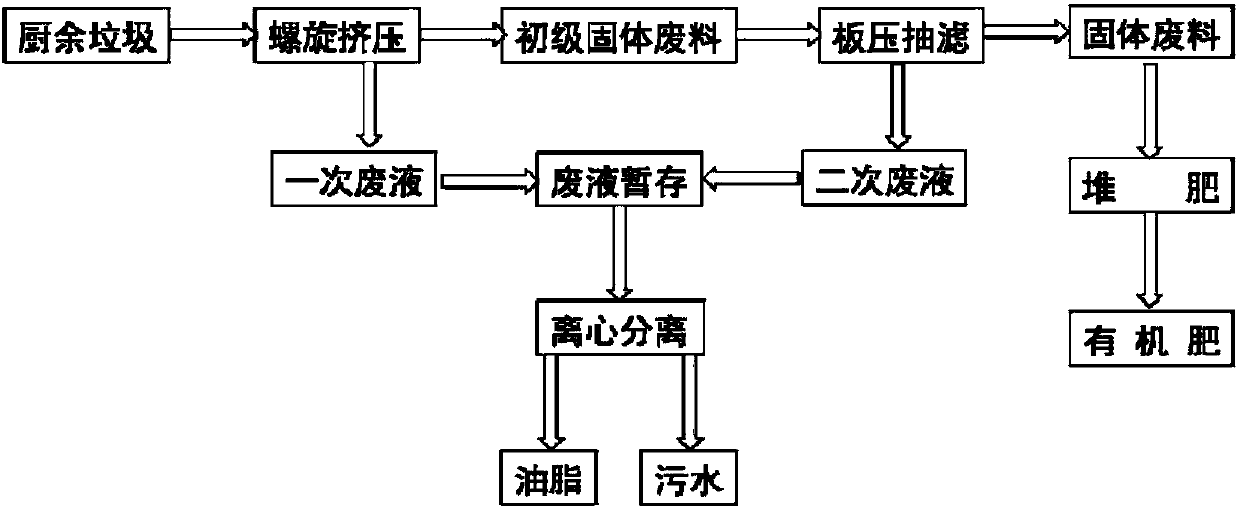

[0022] Such as figure 1 A food waste source classification and pretreatment system is shown, the system includes a solid-liquid separation unit, a rapid fermentation unit, a water-oil separation unit and a control unit, the solid-liquid separation unit, rapid fermentation unit, water-oil separation unit The power part and the movable components are automatically controlled by the control unit; the solid-liquid separation unit includes a screw extrusion device 1 and a plate pressure suction filtration device 2; the fast fermentation unit includes a solid storage tank 7 and a fast fermentation device 9; The water-oil separation unit includes a waste liquid storage tank 3 communicated with the screw extruding device 1 and the plate pressure suction filter device 2, a centrifugal separation device 4 communicated with the waste liquid outlet 32 of the waste liquid storage tank 3, and a centrifuge Viscosity responsive shunt device communicated with the discharge control valve 42 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com