Method for producing astaxanthin

A production method, technology of astaxanthin, is applied to light irradiation. field, which can solve problems such as inability to judge astaxanthin production, failure to mention astaxanthin production stage, and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

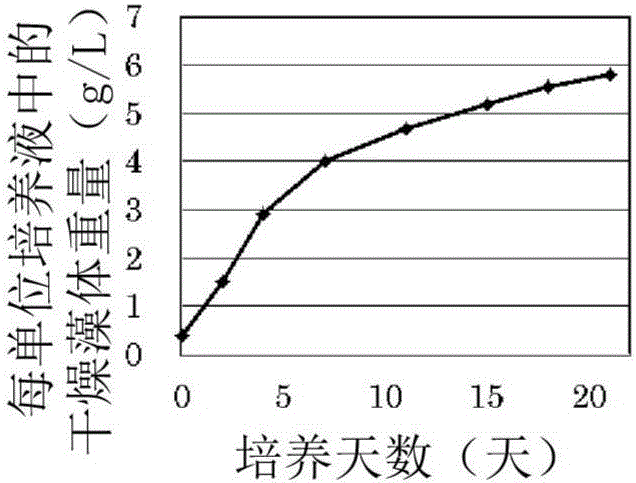

[0079] Culture of Haematococcus (proliferation culture)

[0080] 15 ml of culture solution of Haematococcus lacustrine (H. lacustris) NIES144 strain (preserved by the Microorganism System Preservation Facility of the National Institute of Environmental Research) and BG11 modified A medium (Table 1) containing planktonic cells with a cell number of 500,000 ) 750 ml into four transparent culture containers made of glass with an inner diameter of 50 mm and a height of 500 mm. The luminous flux density becomes 50μmol / m 2 Continuous light irradiation with a fluorescent lamp was carried out in a / s mode, and the air containing 1% carbon dioxide was passed through at 25° C., and cultured while stirring. As a result, the proliferation of planktonic cells was confirmed to be 450,000 / ml on the fifth day of culture.

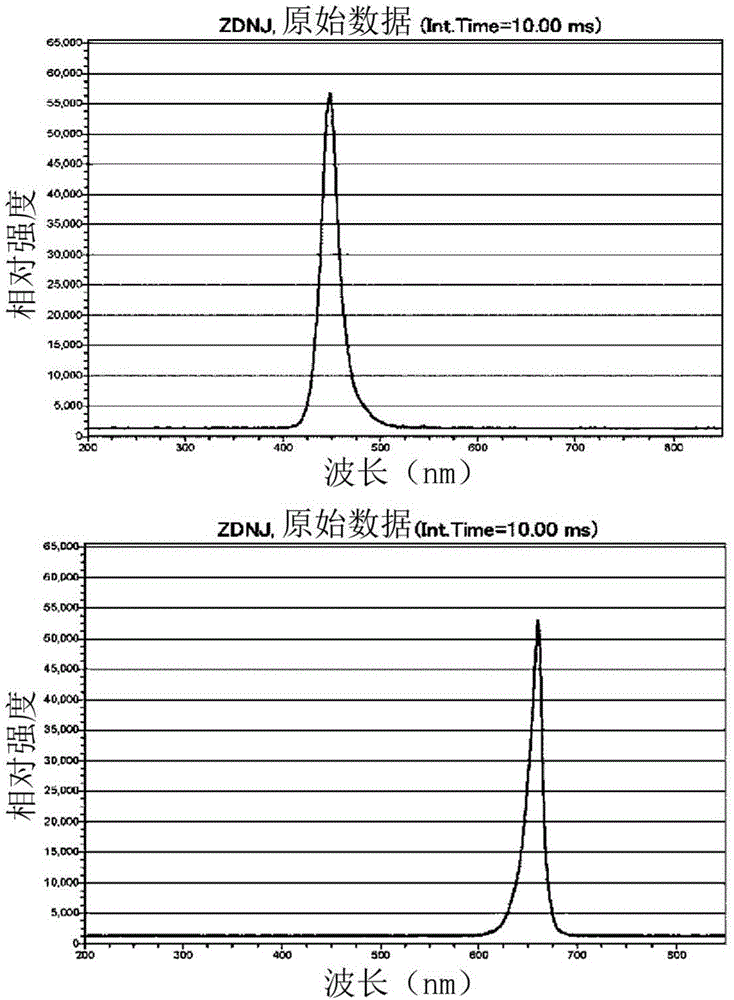

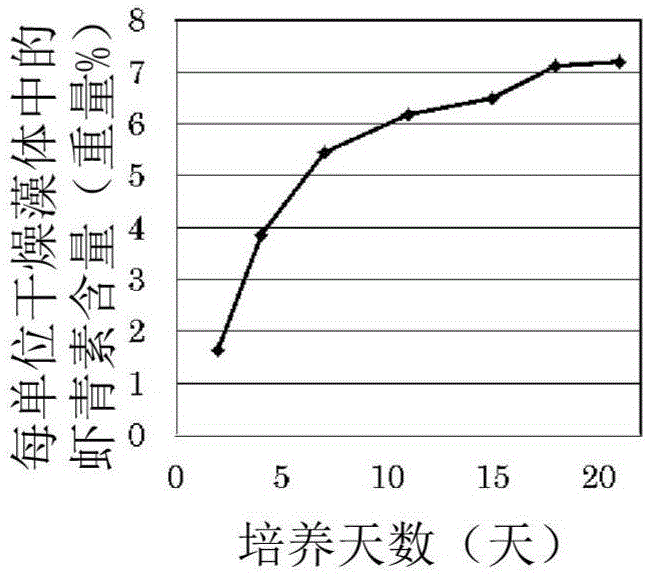

[0081] Cultivation of Haematococcus using various light sources (astaxanthin production culture)

[0082] Next, after adding sodium chloride to the culture solution so t...

Embodiment 2

[0092] Culture of Haematococcus (proliferation culture)

[0093] Inject 15 ml of culture solution of Haematococcus lacustrine (H. lacustris) NIES 144 strain containing 500,000 cells / ml of planktonic cells and 750 ml of BG11 modified B medium (Table 3) into a glass with an inner diameter of 50 mm and a height of 500 mm. in a transparent culture container. By using a blue LED with a wavelength of 450nm (luminous flux density 50μmol / m 2 / s), red light with a wavelength of 660nm (luminous flux density LED 30μmol / m 2 / s) while being continuously irradiated with light, at 25° C., air containing 1% carbon dioxide was blown, and cultured while stirring. As a result, proliferation of 360,000 planktonic cells / ml was confirmed on the fourth day of culture.

[0094] Cultivation of Haematococcus (Astaxanthin Production Cultivation)

[0095] Next, after adding sodium chloride to the culture solution so that the concentration of sodium chloride becomes 2g / L, by using blue light with a wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com