FBAR (Film Bulk Acoustic Resonator) and preparation method thereof

A resonator and monocrystalline silicon technology, which is applied in the field of FBAR and its preparation based on MEMS micromachining technology, can solve the problem of high process cost, achieve simple device structure, reduce size and cost, and realize the effect of single-chip intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

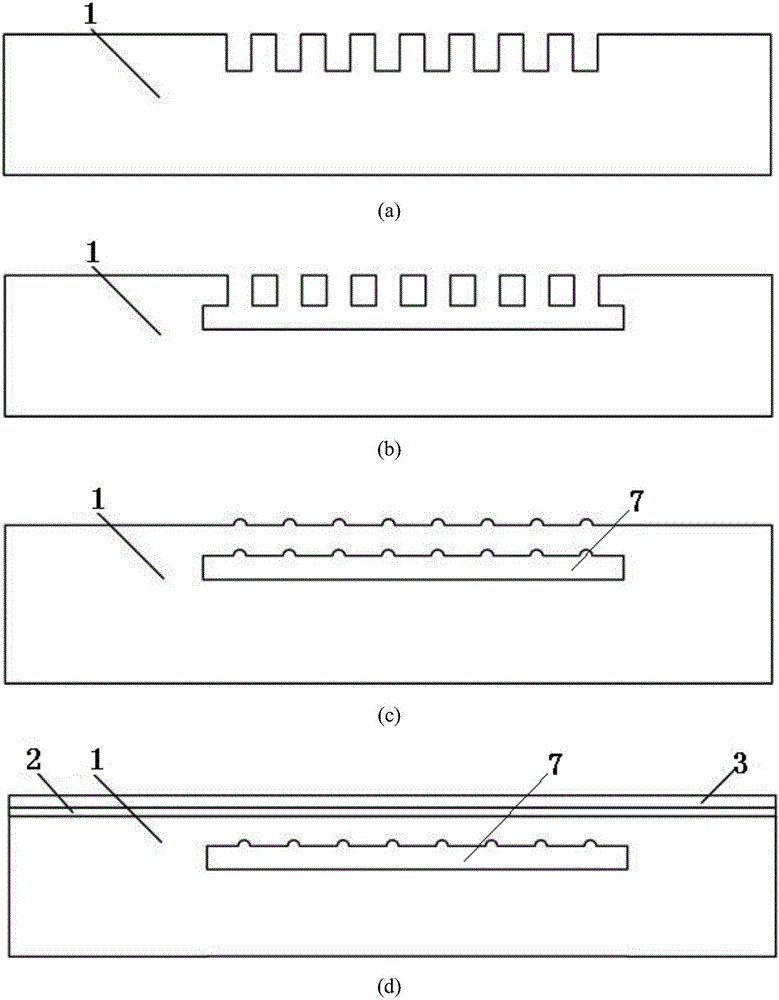

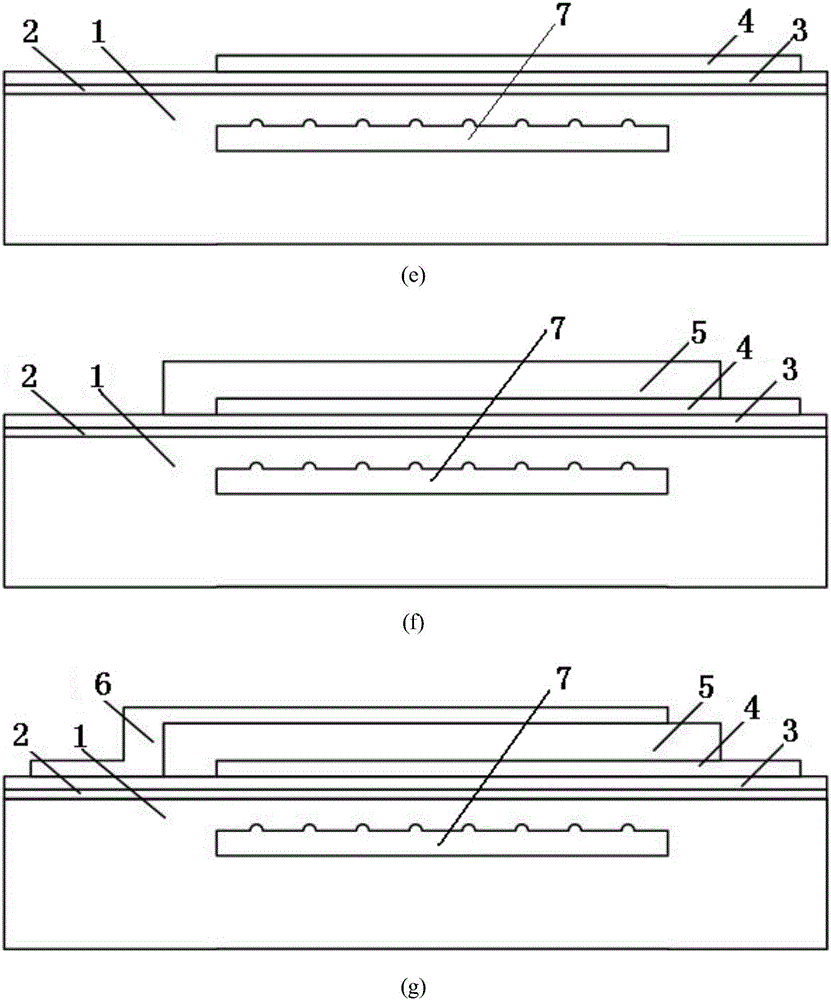

[0021] Such as figure 1 As shown, the FBAR resonator provided by the present invention is prepared through the following steps:

[0022] (a) N-type (100) single crystal silicon is used as the substrate, and shallow grooves are etched on the single crystal silicon substrate 1 by an anisotropic reactive ion etching (RIE) process;

[0023] (b) While protecting the sidewall of the shallow groove of the single crystal silicon substrate 1, perform isotropic etching on the single crystal silicon substrate to prepare for the encapsulation process of the next epitaxial single crystal silicon cavity;

[0024] (c) Epitaxial growth of single crystal silicon, forming a sealed cavity 7 inside the single crystal silicon substrate, and the height of cavity 7 is about 5 μm;

[0025] (d) sequentially growing silicon dioxide 2 and silicon nitride 3 on the upper surface of the single crystal silicon substrate 1, and forming contact holes by photolithography and etching;

[0026] (e) Sputtering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com