Silicon/carbon nano composite fiber and application thereof

A carbon nanocomposite, composite nanofiber technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as decline, electrode material structure crushing capacity, and unsatisfactory performance. Deactivation and loss of electrical contact, improving structural and electrochemical stability, preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

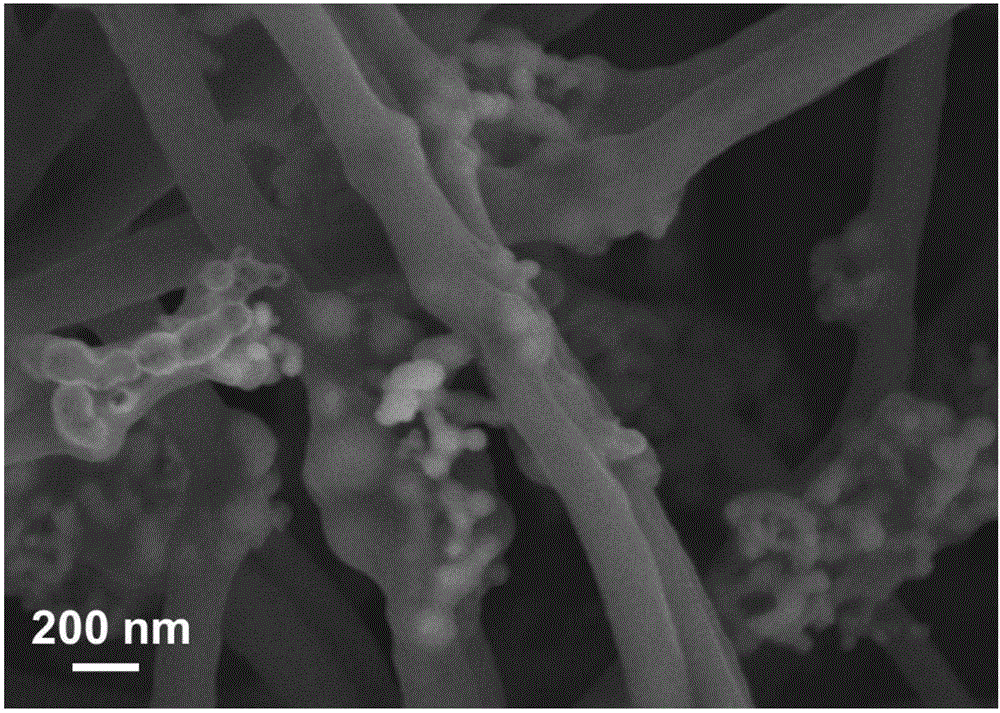

[0037] (1) Disperse 200 mg of silicon nanoparticles into 400 mL of ethanol / water mixed solution, where the volume ratio of ethanol to water is 4:1 (V:V). Add 4.0 mL of concentrated ammonia water and 2.0 g of ethyl orthosilicate dropwise to the mixed solution. The mixed solution was stirred at room temperature for 12 h, then centrifuged, washed with ethanol three times, and dried at 80 °C to obtain Si@SiO with a core-shell structure. 2 particles.

[0038] (2) Use an electronic balance to take 0.2g of Pingpingjia O and dissolve it in 5g of N-N dimethylformamide, put it in a 20mL sample bottle, heat and stir at 60°C until it is completely dissolved. Then take 0.2 g Si@SiO with a balance 2 , 0.4g of polyacrylonitrile was dissolved in the mixed solution, the sample bottle was sealed with a parafilm, stirred at 60°C for 24 h, and ultrasonically dispersed at room temperature for 1 h to obtain a uniformly dispersed spinning solution. Cut out an aluminum foil paper with a size of 40...

Embodiment 2

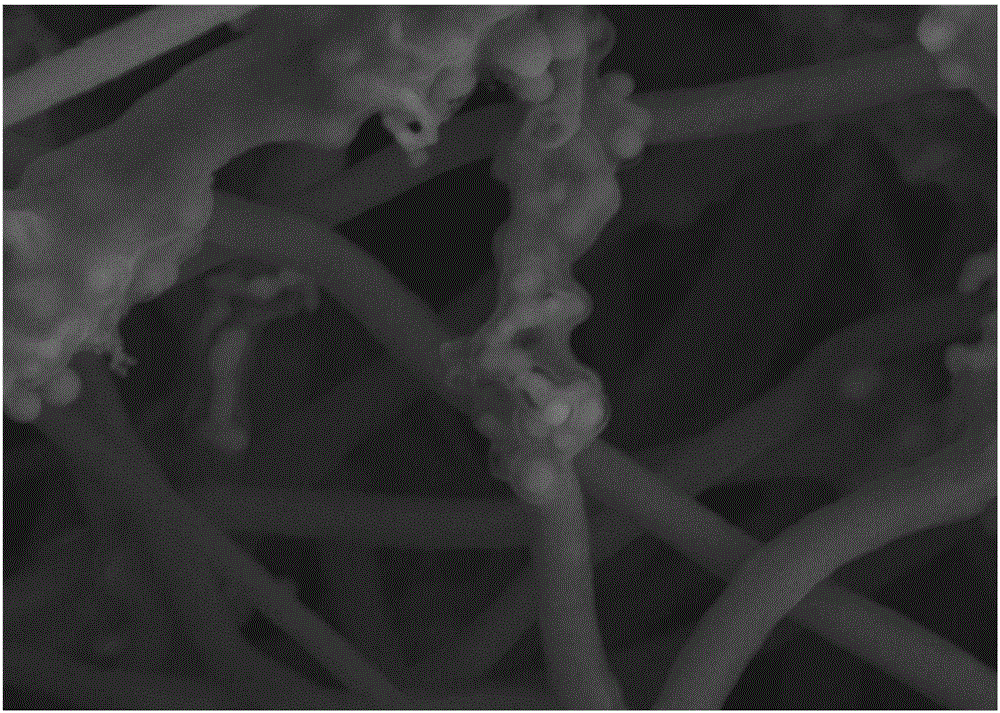

[0044] (1) Disperse 200 mg of silicon nanoparticles into 400 mL of ethanol / water mixed solution, where the volume ratio of ethanol to water is 4:1 (V:V). Add 4.0 mL of concentrated ammonia water and 2.0 g of ethyl orthosilicate dropwise to the mixed solution. The mixed solution was stirred at room temperature for 12 h, then centrifuged, washed with ethanol three times, and dried at 80 °C to obtain Si@SiO2 particles with a core-shell structure.

[0045] (2) Dissolve 0.2 g of Pingpinga O in 5 g of N-N dimethylformamide with an electronic balance, place it in a 20 mL sample bottle, and heat and stir at 60°C until completely dissolved. Afterwards, 0.2 g Si@SiO2 and 0.4 g polyacrylonitrile were dissolved in the mixed solution with a balance, and the sample bottle was sealed with a parafilm, stirred at 60°C for 24 hours, and ultrasonically dispersed at room temperature for 1 hour to obtain a uniformly dispersed spinning solution. Cut out an aluminum foil paper with a size of 40 cm ...

Embodiment 3

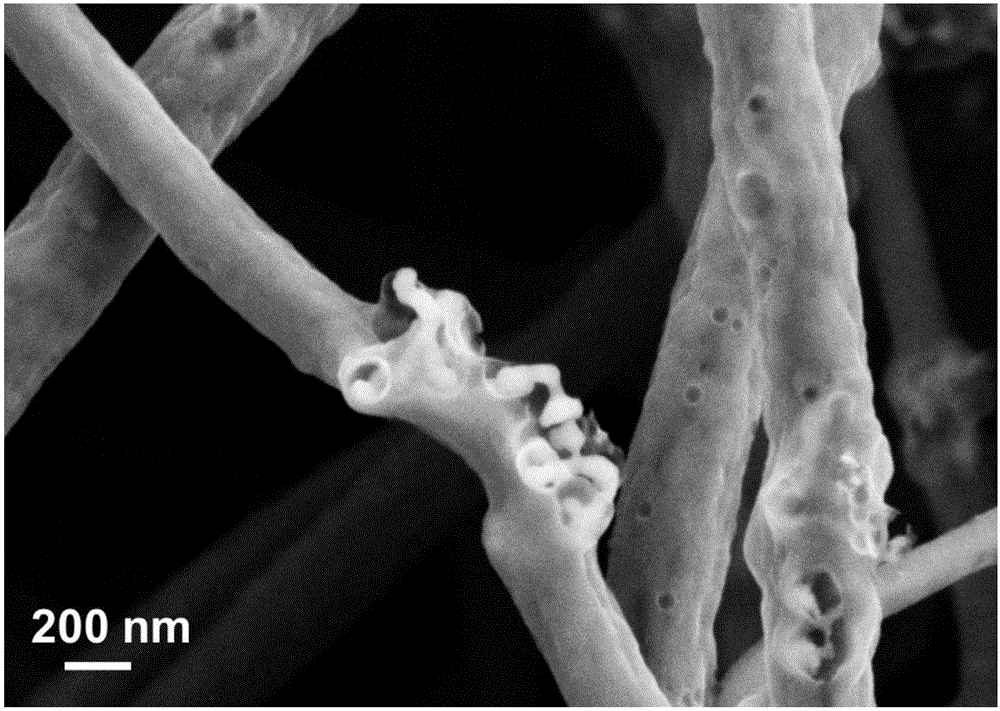

[0052] (1) Disperse 200 mg of silicon nanoparticles into 400 mL of ethanol / water mixed solution, where the volume ratio of ethanol to water is 4:1 (V:V). Add 4.0 mL of concentrated ammonia water and 2.0 g of ethyl orthosilicate dropwise to the mixed solution. The mixed solution was stirred at room temperature for 12 h, then centrifuged, washed with ethanol three times, and dried at 80 °C to obtain Si@SiO with a core-shell structure. 2 particles.

[0053] (2) Dissolve 0.2 g of Pingpinga O in 5 g of N-N dimethylformamide with an electronic balance, place it in a 20 mL sample bottle, and heat and stir at 60°C until completely dissolved. Then take 0.2g Si@SiO with a balance 2 , 0.4 g of polyacrylonitrile was dissolved in the mixed solution, the sample bottle was sealed with a parafilm, stirred at 60 °C for 24 hours, and ultrasonically dispersed at room temperature for 1 h to obtain a uniformly dispersed spinning solution. Cut out an aluminum foil paper with a size of 40 cm × 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com