Roller bit with roller pull-off prevention alarm apparatus

A technology of early warning device and roller cone bit, which is used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of reduced bearing capacity, failure of anti-separation effect, plastic deformation of circlip grooves, etc., and achieves reduction in width and depth. , The effect of reducing drilling cost and increasing bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

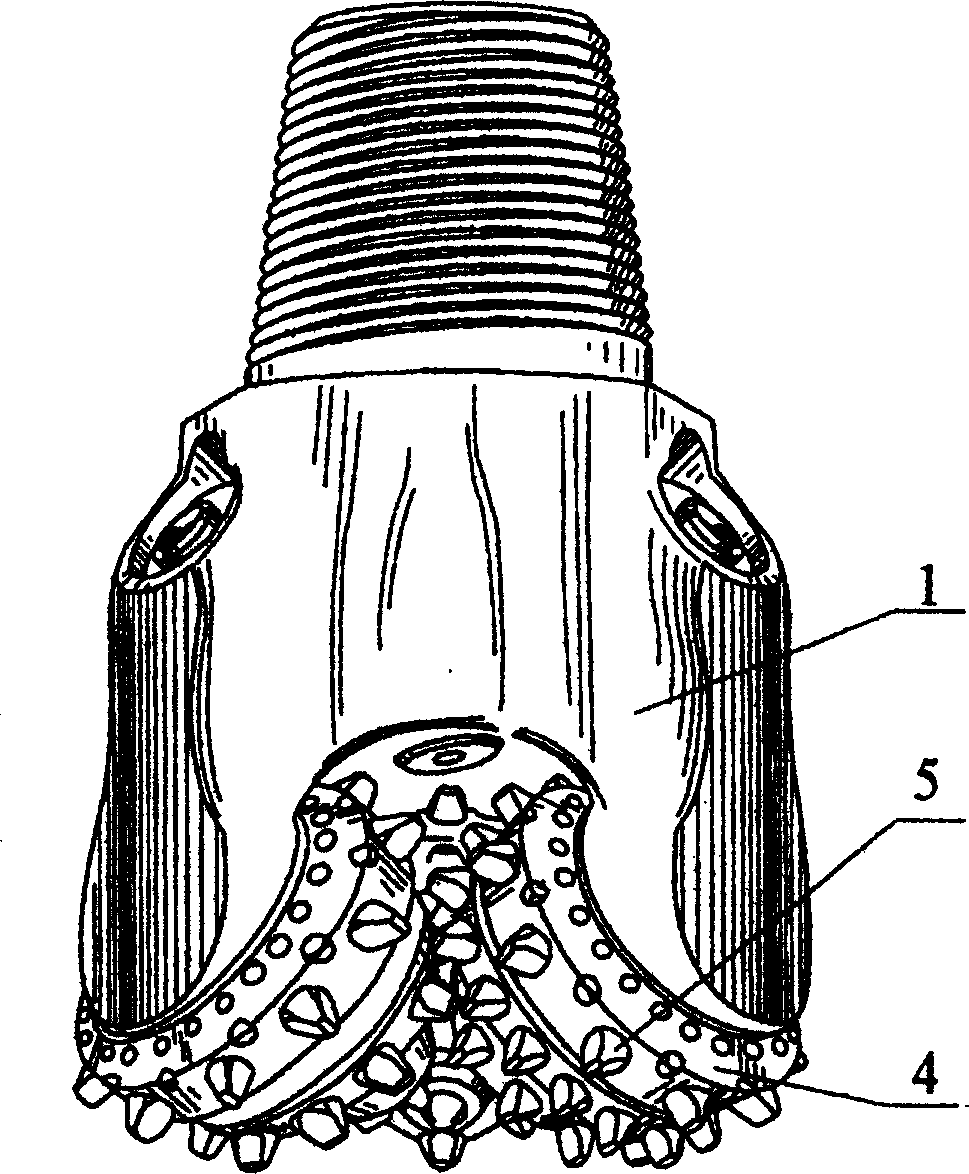

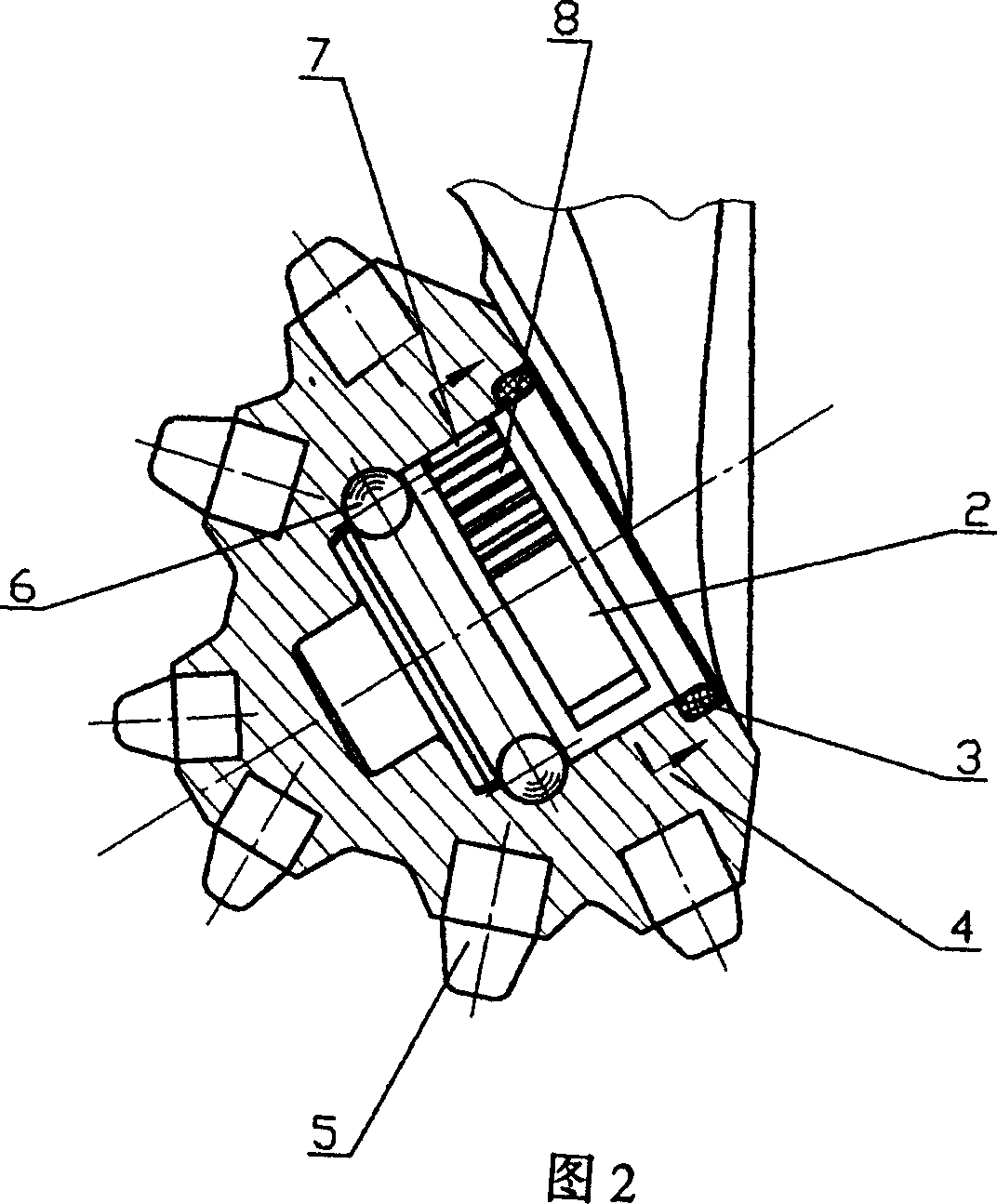

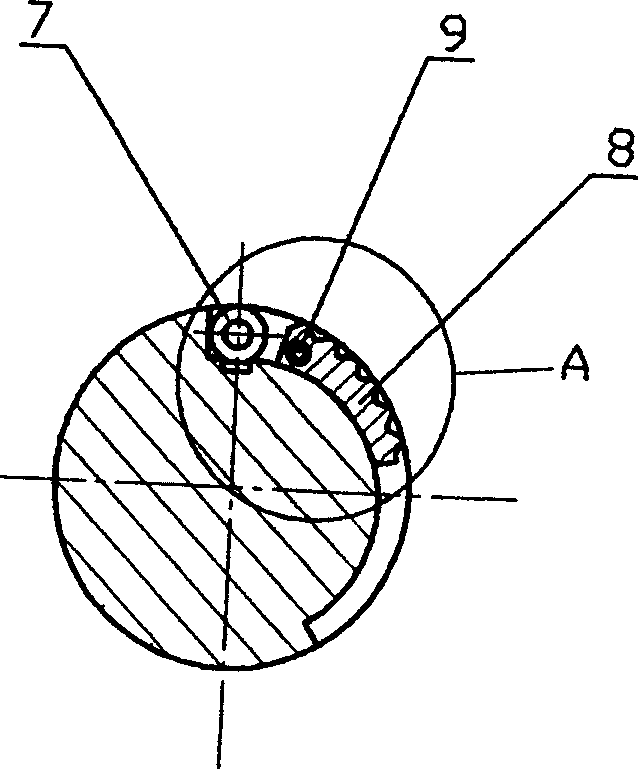

[0030] The components of the roller cone bit are the same as those of the existing roller cone bit, mainly consisting of a bit body (1) and a roller cone (4), teeth (5) are arranged on the roller cone (4), and the teeth (5) of the roller cone (4) The inner hole is installed on the claw journal (2) of the drill bit body (1), and cooperates with each other to form a gear claw bearing pair. The roller cone bits can be single cone bits, double cone bits, triple cone bits or multi-cone bits, figure 1 A schematic diagram of a tricone bit is shown. Teeth (5) can be inlaid or milled. There is a sealing ring (3) and a locking device (6) for positioning and anti-loosening between the bearing pairs of the gear teeth and claws. The locking device can be a steel ball locking device, or a circlip or other types of locking devices. The locking device (6) shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com