Structure and preparation method of a flexible perovskite battery

A perovskite and battery technology, applied in the field of solar cells, can solve the problems of reducing bottom electrode resistance, poor heat resistance of flexible substrates, etc., to achieve the effects of reducing series resistance, increasing light absorption, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

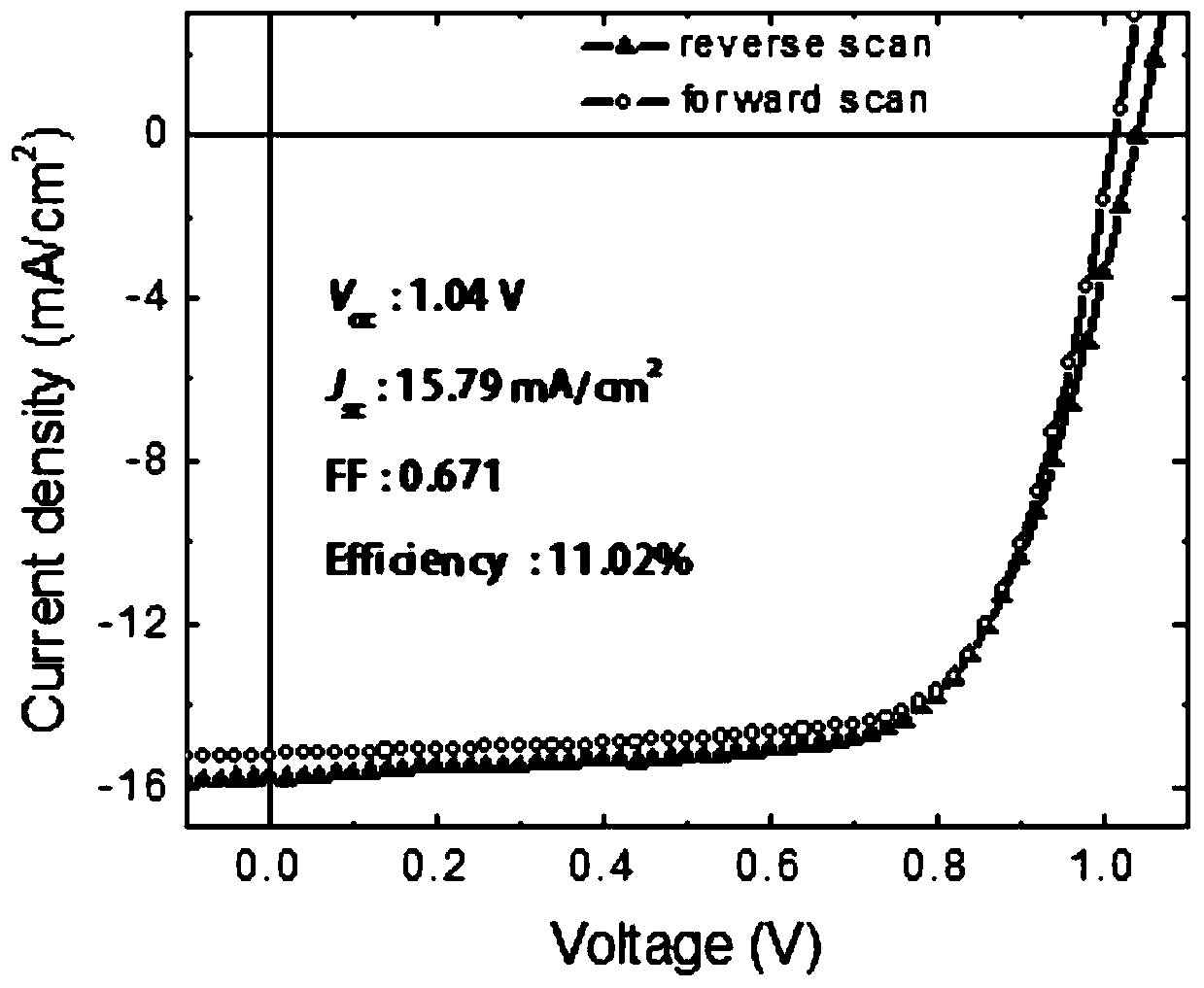

Examples

Embodiment 1

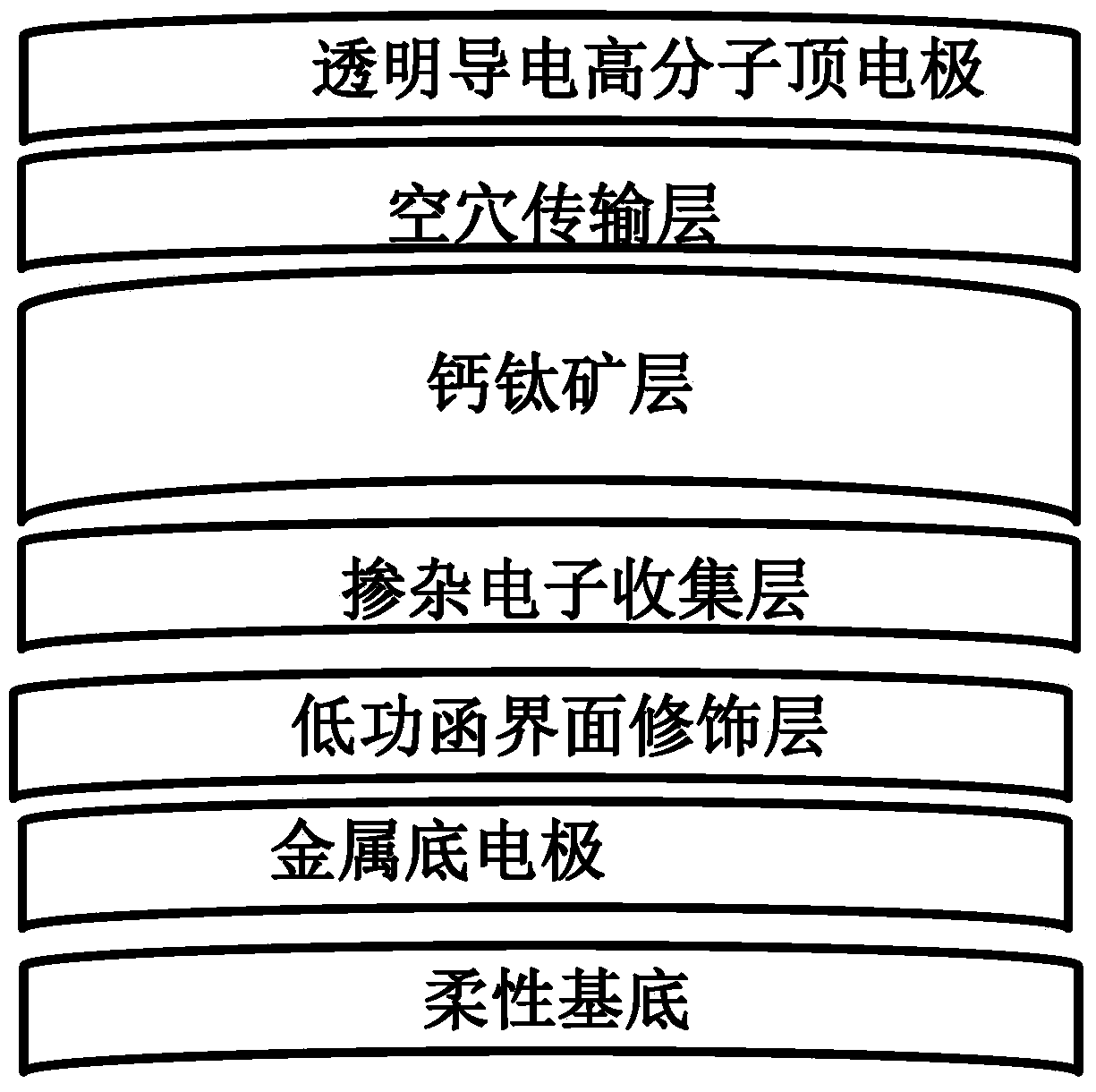

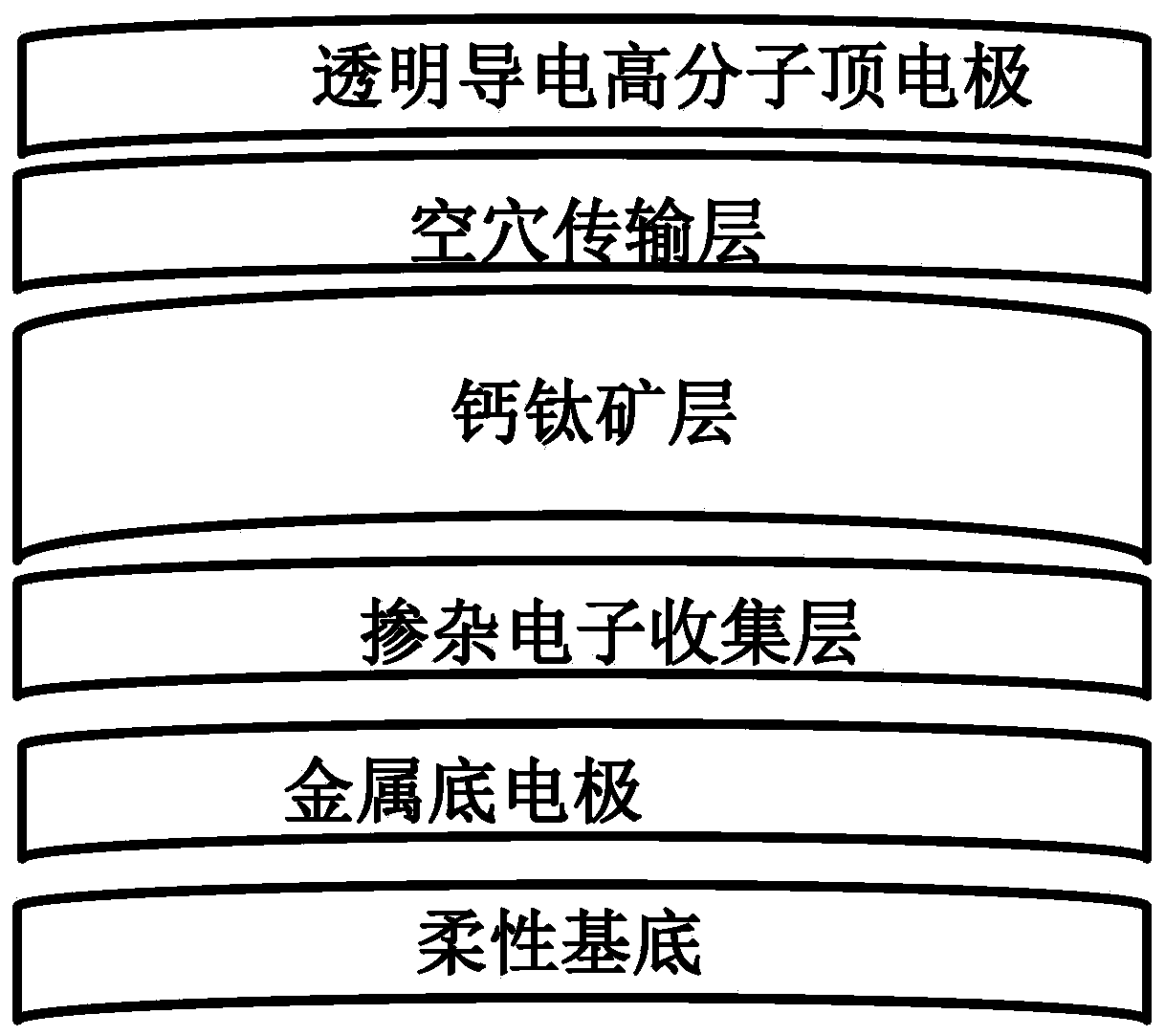

[0035] according to figure 1 structure, the preparation method of the flexible perovskite solar cell described in the present invention is as follows:

[0036] (1) Preparation of the bottom electrode: Deposit a layer of 70nm Ag electrode on a clean flexible substrate by thermal evaporation as the bottom electrode;

[0037] (2) Preparation of a low work function interface modification layer: a layer of PEIE with a thickness of 10 nm was obtained on a flexible substrate by spin coating, soaking, or spraying, and dried at 100 ° C for 10 min;

[0038] (3) Preparation of the doped electron collection layer: a layer of n-doped PCBM with a thickness of 70 nm was obtained on the PEIE by spin coating, soaking, and spraying, and dried at 80 ° C for 5 min;

[0039] (4) Preparation of perovskite light-absorbing layer: the perovskite light-absorbing layer was prepared on n-doped PCBM by anti-solvent method, and dried at 100°C for 10 minutes to obtain a perovskite layer with a thickness of...

Embodiment 2

[0044] according to figure 1structure, the preparation method of the flexible perovskite solar cell described in the present invention is as follows:

[0045] (1) Preparation of the bottom electrode: Deposit a layer of 50nm Ag electrode on a clean flexible substrate by thermal evaporation as the bottom electrode;

[0046] (2) Preparation of a low work function interface modification layer: A layer of PEIE with a thickness of 5 nm was obtained on a flexible substrate by spin coating, soaking, or spraying, and dried at 70°C for 10 min;

[0047] (3) Preparation of the doped electron collection layer: a layer of n-doped PCBM with a thickness of 50 nm was obtained on the PEIE by spin coating, soaking, and spraying, and dried at 80 ° C for 10 min;

[0048] (4) Preparation of perovskite light-absorbing layer: The perovskite light-absorbing layer was prepared on n-doped PCBM by anti-solvent method, and dried at 90°C for 10 minutes to obtain a perovskite layer with a thickness of abou...

Embodiment 3

[0052] according to figure 1 structure, the preparation method of the flexible perovskite solar cell described in the present invention is as follows:

[0053] (1) Preparation of the bottom electrode: Deposit a layer of 100nm Ag electrode on a clean flexible substrate by thermal evaporation as the bottom electrode;

[0054] (2) Preparation of a low work function interface modification layer: A layer of PEIE with a thickness of 15 nm was obtained on a flexible substrate by spin coating, soaking, or spraying, and dried at 100 ° C for 5 min;

[0055] (3) Preparation of the doped electron collection layer: a layer of n-doped PCBM with a thickness of 80 nm was obtained on the PEIE by spin coating, soaking, and spraying, and dried at 100 ° C for 5 min;

[0056] (4) Preparation of perovskite light-absorbing layer: The perovskite light-absorbing layer was prepared on n-doped PCBM by anti-solvent method, and dried at 110°C for 5 minutes to obtain a perovskite layer with a thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com