Parallel optical assembly

An optical component and laser technology, applied in optical components, light guides, optics, etc., can solve the problems of poor assembly accuracy of electrical connectors and optical connectors, complex coupling process, large package size, etc., to achieve small package size, avoid damage, Good thermal matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below, and it should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

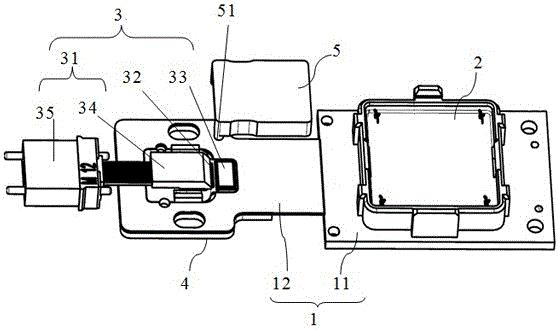

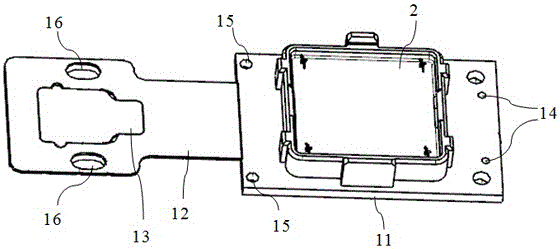

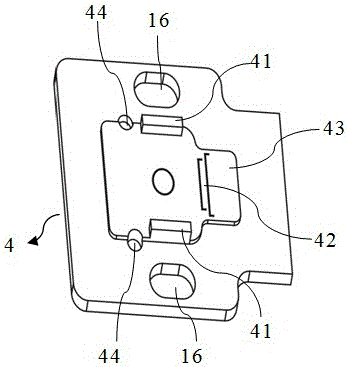

[0023] Such as Figure 1-Figure 4 As shown, the parallel optical assembly of this embodiment includes a PCB board 1, an electrical connector 2 and an optical connector 3 installed on the PCB board 1, and the optical connector 3 includes an FA fiber array assembly 31, a VCSEL laser or a PD detector 32 and Drive chip 33, PCB board 1 comprises rigid PCB board part 11 and flexible PCB board part 12, electrical connector 2 is arranged on the rigid PCB board part 11; The metal reinforcement plate 4 is provided with two parallel FA fixed bosses 41, a VCSEL laser or PD detector positioning identification area 42 and a drive chip positioning identification area 43, and the VCSEL laser or PD detector position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com