Novel mechanical transmission structure and device with mechanical transmission structure

A new type of mechanical transmission technology, applied in transmission devices, friction transmission devices, electromechanical devices, etc., can solve the problems of increasing elastic deformation of synchronous belts, affecting transmission efficiency and accuracy, and increasing power transmission delays, so as to improve transmission accuracy. and speed, easy installation and commissioning, fast power delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

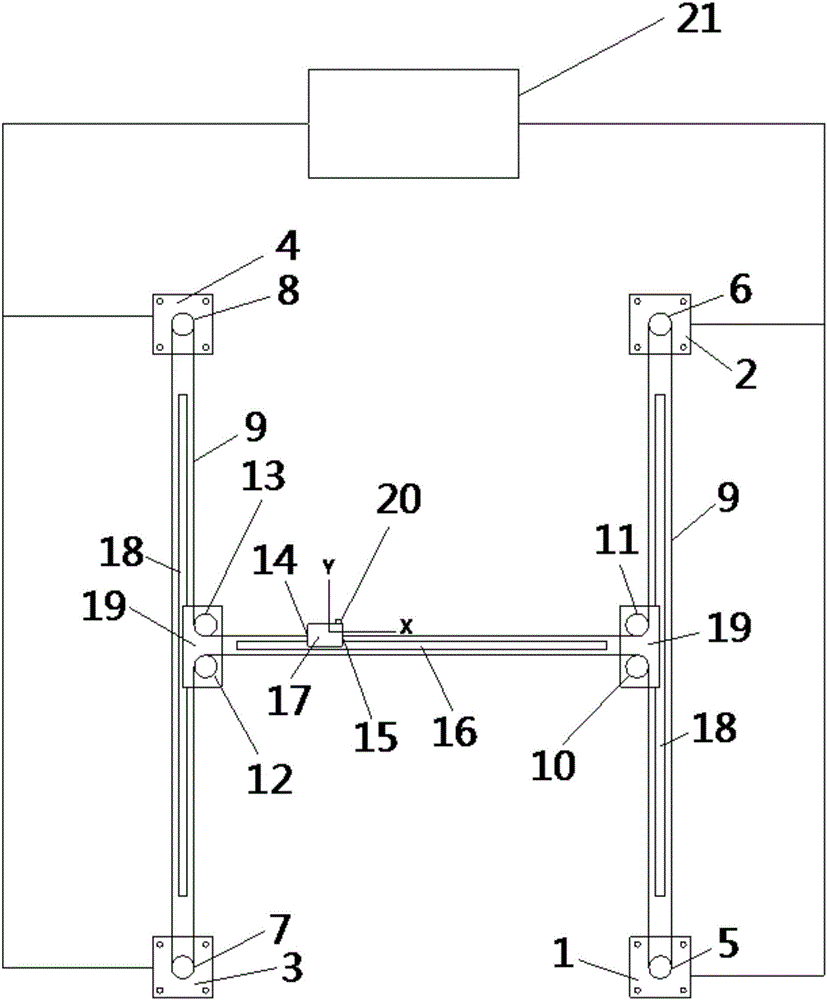

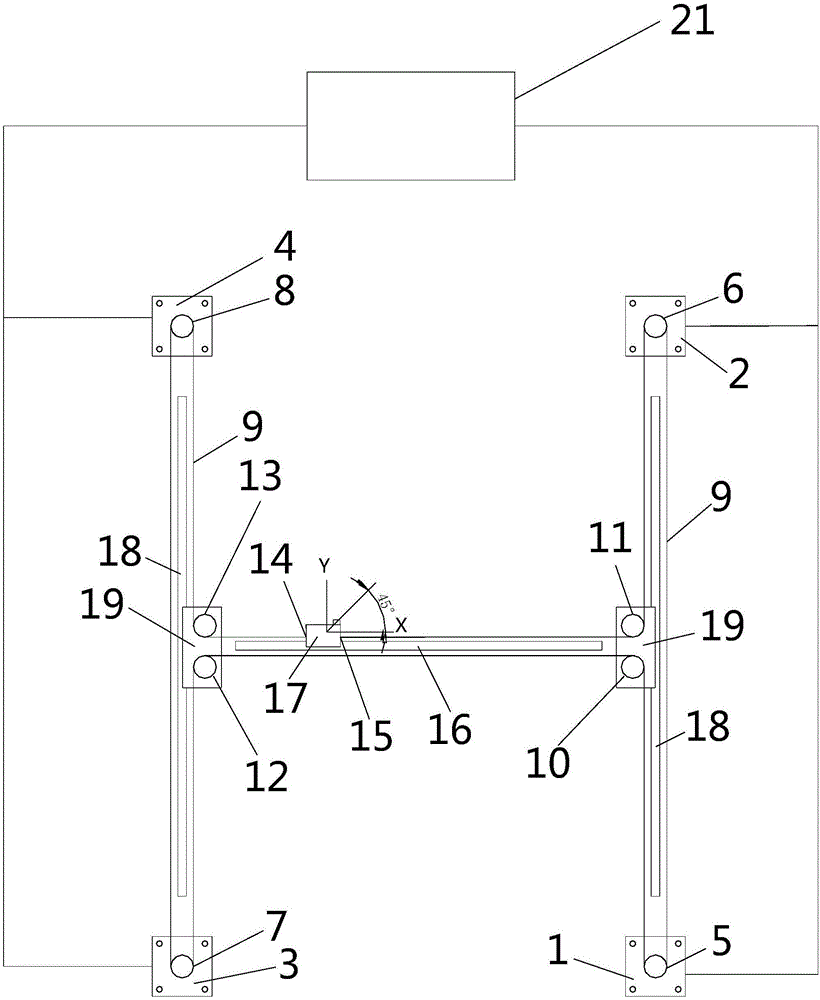

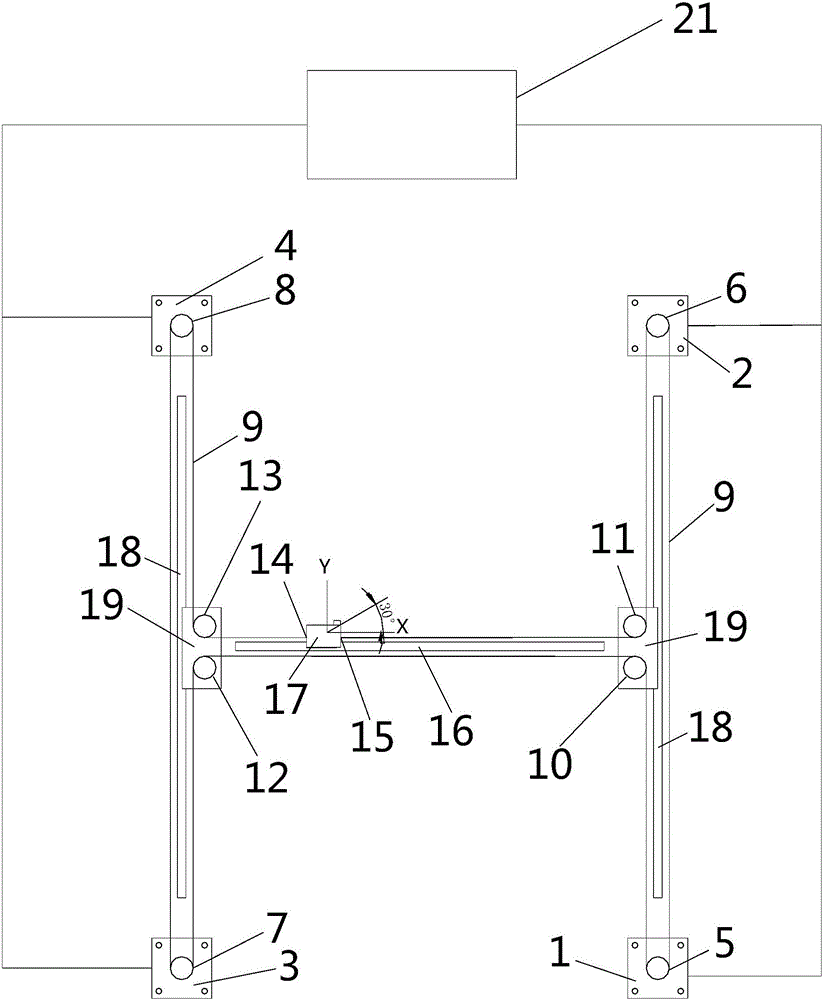

[0043] Embodiment 1: A kind of novel mechanical transmission structure, its structure is as figure 1 shown, including:

[0044] The Y-direction slide rails 18 located on the left and right sides have a Y-direction slide block 19 on each Y-direction slide rail 18; two Y-direction slide blocks 19 are fixedly connected to the two ends of the same X-direction slide rail 16, An X-direction slide block 17 is provided on the X-direction slide rail 16 , and the X-direction slide rail 16 is perpendicular to the Y-direction slide rail 18 .

[0045] The upper and lower ends of the left Y direction slide rail 18 are respectively provided with a fourth motor 4 and the third motor 3; the upper and lower ends of the right Y direction slide rail 18 are respectively provided with a second motor 2 and a second motor 2 A motor 1 .

[0046] Wherein, the first synchronous wheel 5 is installed on the first motor 1, the second synchronous wheel 6 is installed on the second motor 2, the 3rd synchro...

Embodiment 2

[0061] Embodiment 2: A device, on which a two-axis linkage mechanical structure of the X-axis and the Y-axis is installed. Wherein, the structure is the structure shown in Embodiment 1.

Embodiment 3

[0062] Embodiment 3: a 3D printer, the 3D printer has at least a two-axis and two-linkage structure. Wherein, the printer adopts the transmission structure shown in Embodiment 1, and the working module 20 on the printer is replaced by an extrusion head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com